Understanding the inner workings of a chainsaw is essential for proper care and effective operation. Having access to clear visual references of its components can make a world of difference when diagnosing issues or performing maintenance tasks. Knowing the location and function of each part helps in ensuring your tool remains in top working condition.

In this guide, we will explore how to navigate through technical diagrams, highlighting key components and providing useful tips for performing repairs or replacements. Whether you’re a seasoned professional or a novice, this information will assist you in extending the life of your equipment and preventing costly mistakes.

Regular upkeep is crucial for maintaining performance and safety. By gaining familiarity with each section of your tool, you can address any issues quickly, ensuring your chainsaw operates efficiently with minimal downtime.

Understanding the Chainsaw Components

Each tool used for cutting and logging consists of numerous interconnected parts that work together to achieve optimal performance. Understanding the layout and function of each individual piece is crucial for troubleshooting, maintenance, and repairs. Familiarity with your tool’s components allows for quicker identification of issues and better decision-making when it comes to replacements or adjustments.

Key Elements of a Cutting Tool

At the heart of every chainsaw are its engine, drive system, and cutting assembly. These systems are responsible for converting fuel into power, transferring that energy to the chain, and enabling the cutting action. The engine typically includes components like the cylinder, carburetor, and spark plug, each playing a vital role in ensuring smooth operation.

Fuel and Lubrication Systems

Proper fuel and lubrication systems are essential for preventing wear and tear on internal components. A well-maintained fuel system ensures efficient combustion, while lubrication reduces friction between moving parts. Regular checks of these systems can prevent common issues such as overheating or excessive vibration, contributing to the longevity of the tool.

How to Read the Parts Diagram

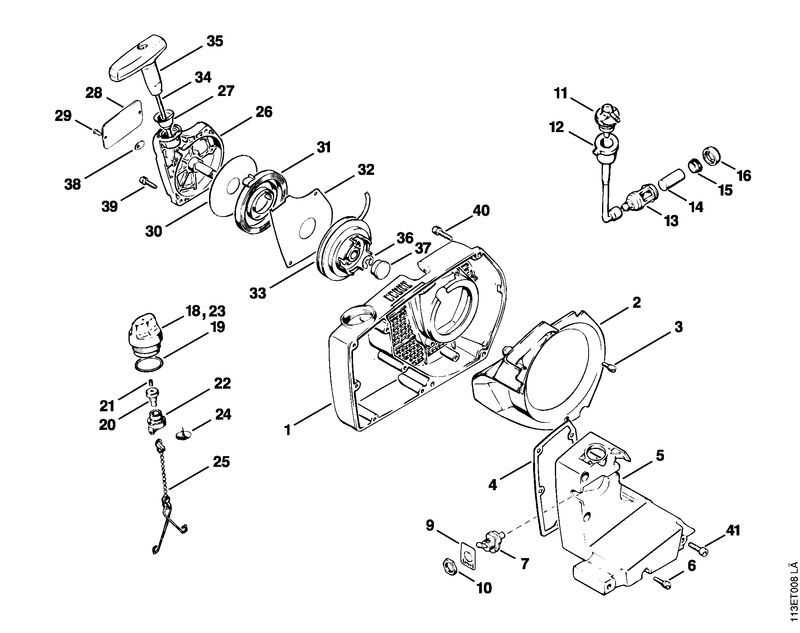

Being able to understand technical diagrams is an essential skill when maintaining and repairing equipment. These illustrations provide a clear overview of all the individual components, showing how they are interconnected and how each part functions within the system. Reading these visuals can help pinpoint the source of a problem and guide you in making the right fixes or replacements.

To effectively interpret such a diagram, follow these basic steps:

- Identify the key legend – Most diagrams feature a legend that explains the symbols and numbers used. This is crucial for understanding the meaning of each label and the reference numbers corresponding to the parts.

- Understand the layout – Components are often grouped by their function. Pay attention to how each section is organized, such as the engine components or the cutting assembly.

- Locate the reference numbers – Each part in the diagram is usually assigned a unique reference number, which corresponds to its listing in the manual. These numbers make it easier to find the exact replacement or part you need.

By following these steps, you’ll be able to navigate technical illustrations more effectively and ensure that you make informed decisions when handling maintenance tasks.

Common Repairs for Chainsaw Models

Chainsaws, like all mechanical tools, require regular maintenance and occasional repairs to ensure they operate at peak performance. Common issues typically arise in areas such as the engine, fuel system, or cutting assembly. Recognizing these problems early and addressing them promptly can prevent larger, more expensive failures.

One of the most frequent repairs involves the fuel system. Over time, the carburetor or fuel lines can become clogged, leading to poor engine performance or failure to start. Replacing a worn-out fuel filter or cleaning the carburetor can restore the tool’s power and efficiency.

Another common repair is replacing the drive components, including the clutch and sprocket. These parts endure significant wear from continuous use, leading to decreased cutting speed or power transfer. Regular inspection and timely replacement of these parts will help maintain smooth operation.

Finally, the cutting assembly itself, including the chain and guide bar, may need attention. Overuse or improper lubrication can cause the chain to stretch or the bar to wear unevenly, affecting performance. Regular sharpening of the chain and proper maintenance of the bar can significantly extend the life of these components.

Parts Replacement Tips and Tricks

Replacing worn or damaged components is an essential part of keeping your equipment functioning properly. Whether you’re a professional or a hobbyist, knowing the right approach to part replacement can save you time, money, and effort. With the correct techniques, you can ensure that each component performs optimally for the long term.

Tip 1: Always use high-quality replacement components. While it may be tempting to opt for cheaper alternatives, using genuine or high-quality parts ensures compatibility and longevity. Poor-quality parts can cause further damage and affect the overall performance of your tool.

Tip 2: Before replacing any component, take the time to clean the area thoroughly. Dirt and debris can interfere with the fitting of new parts, leading to unnecessary wear. Clean the surrounding parts with a soft cloth and ensure the area is free from any buildup.

Tip 3: Keep track of any specific torque requirements. Some parts, like the engine or handle assembly, require precise torque when being installed. Using a torque wrench can help you avoid over-tightening or under-tightening, which could damage the components.

Tip 4: Always refer to the user manual or a detailed guide when replacing components. Understanding the assembly process ensures that you don’t miss any crucial steps. If you’re unsure, watching tutorial videos or consulting a professional can prevent mistakes.

Maintaining Your Chainsaw

Proper maintenance is key to ensuring the longevity and efficiency of your chainsaw. Regular care not only keeps your equipment running smoothly but also helps avoid unexpected breakdowns during use. A well-maintained chainsaw operates more safely and effectively, saving you both time and money in repairs.

Routine Cleaning and Lubrication

One of the simplest and most effective ways to maintain your tool is through routine cleaning. After each use, wipe down the chainsaw, removing dirt, debris, and sap that can accumulate. Ensure that the chain is properly lubricated to minimize wear and friction during operation. Proper lubrication reduces the chance of overheating and extends the life of the cutting components.

Inspecting and Replacing Worn Parts

Regularly check for signs of wear on critical components such as the chain, bar, and spark plug. If the chain becomes dull or the bar is damaged, replace them promptly to maintain cutting performance. Likewise, inspect the fuel and air filters, as well as the spark plug, ensuring they are clean and in good condition. Regular part replacement ensures your tool operates at peak efficiency.

Tip: Always refer to the user manual for specific maintenance intervals and procedures for your model. Following the manufacturer’s recommendations will help you avoid mistakes and ensure that your chainsaw stays in top working order.