When working with any machinery, it’s crucial to have a clear understanding of its individual components and how they function together. Knowing the layout and structure of each part helps improve both maintenance and troubleshooting. Proper knowledge can extend the life of your equipment and ensure smooth operation during use.

Identifying each component of the chainsaw is an essential step in performing repairs or replacements. With the right resources, you can identify issues early and make the necessary adjustments without professional help. This process becomes much easier when you have access to an organized guide that breaks down all parts.

Whether you’re looking to replace a specific part or just want to familiarize yourself with the inner workings, understanding the system behind your tool is a vital skill. This will enable you to troubleshoot issues quickly, saving you time and money on unnecessary repairs.

Understanding the Chainsaw Components

To ensure your equipment runs efficiently, it’s essential to have a clear understanding of its internal structure. Each tool is made up of various sections, each playing a critical role in its performance. Gaining knowledge of these sections allows for easier identification of potential issues and helps in performing precise repairs or replacements.

Key Functional Elements

The core functionality of any machine depends on its central components working in harmony. Some of the key elements include the engine, the fuel system, and the ignition system. These parts are responsible for generating power, ensuring smooth operation, and starting the machine reliably. Understanding how each of these systems functions will make diagnosing problems far more manageable.

Commonly Replaced Components

Over time, certain sections of the equipment may wear out or need regular maintenance. These parts, such as the fuel filter, air filter, and spark plug, are frequently replaced due to normal usage. Recognizing these components and their role in the machine’s overall operation ensures that you can make timely replacements, preventing more significant malfunctions later on.

How to Read the Equipment Layout

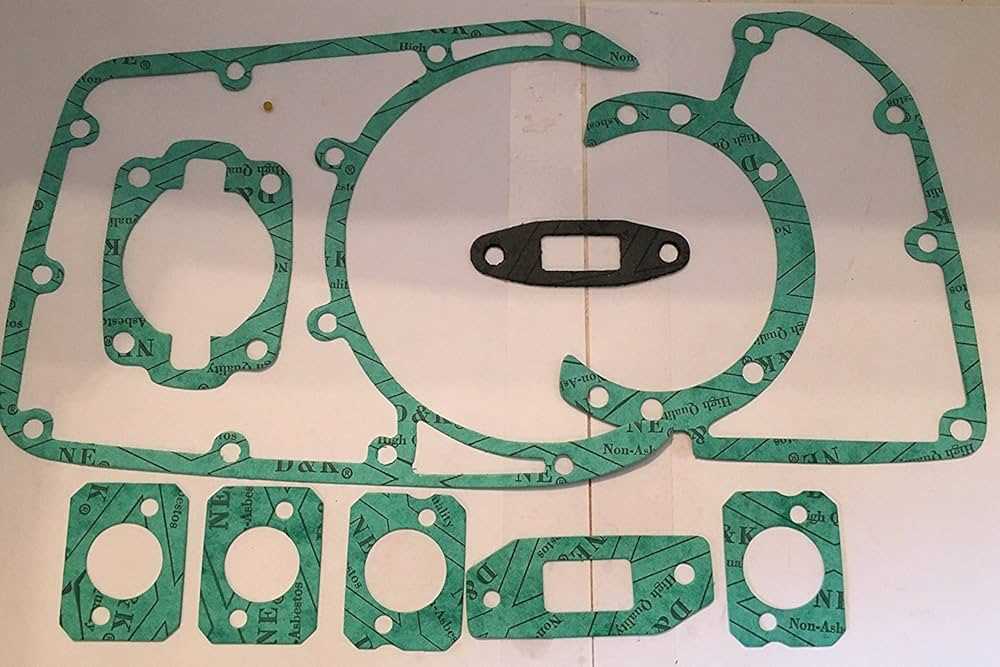

Understanding a visual layout of your tool’s components can simplify the process of identifying, replacing, or maintaining different parts. By interpreting the layout correctly, you can easily match each item with the corresponding section of your equipment. This helps avoid confusion and ensures efficient repair or maintenance tasks.

Interpreting the Visual Guide

Most schematics include a clear representation of each component with labeled identifiers. These labels correspond to numbered references, which can then be matched with the listed part names. Paying attention to the order of the components helps understand how they fit together, providing a comprehensive overview of the entire assembly.

Using the Reference Numbers

Reference numbers are crucial when navigating a layout. They allow you to cross-reference with a detailed list of items, helping you identify the exact part needed for replacement or inspection. Knowing how to quickly find these numbers will save time when looking for a specific component in the parts catalog.

Common Replacement Components for Your Tool

Over time, certain components in your equipment may wear out or fail due to regular use. Understanding which sections are most likely to require replacement can help you prepare for maintenance and avoid extended downtime. Regularly replacing these components ensures the smooth operation of your tool and extends its lifespan.

Frequently Replaced Elements

Among the most common components that need replacing are the fuel filter, spark plug, and air filter. These elements are critical to the engine’s efficiency, ensuring proper combustion and airflow. Replacing these parts as they degrade can prevent more severe issues and improve performance.

Other Essential Components to Check

In addition to the engine-related components, the recoil starter, chain brake, and drive sprocket are also subject to wear and tear. These parts should be regularly inspected for damage or excessive wear. Replacing them when needed will ensure that the tool remains safe to operate and functions as intended during demanding tasks.