Every complex machine is built from multiple interconnected elements. To ensure smooth functionality, it is essential to have a clear understanding of how each component works within the system. By exploring the layout of these pieces, you gain insight into their roles and how they support the overall operation.

Knowing the individual parts allows for easier identification of potential problems, as well as effective solutions for repairs or upgrades. A well-organized visual guide helps you see the relationships between components, making maintenance tasks more manageable and efficient.

In this guide, we will delve into the key components of a powerful engine system. By examining the assembly, you will better understand how each piece contributes to the machine’s performance and longevity. Familiarity with these elements is invaluable for anyone working on machine upkeep or troubleshooting.

Understanding Stihl 044 Components

Each machine consists of various interconnected elements, where each plays a vital role in ensuring smooth operation. Understanding the function of these individual components is essential for troubleshooting, maintenance, and performance optimization. By gaining insight into the overall structure, users can effectively manage repairs and upgrades.

Key Components and Their Functions

The primary parts that make up this engine system are designed to work in harmony, with each having a specific function. The engine housing, for example, serves as the base structure, protecting the inner components while providing stability. The fuel and ignition systems are crucial for starting and running the engine, while the intake and exhaust components control airflow for efficient combustion.

Maintenance and Care

Proper maintenance ensures the longevity and optimal performance of the machine. Regular inspection and replacement of worn-out elements, such as the air filter, spark plug, and carburetor, can prevent unexpected breakdowns. Knowing how each part functions will also help in identifying early signs of wear, allowing users to address issues before they lead to more significant problems.

How to Read a Parts Diagram

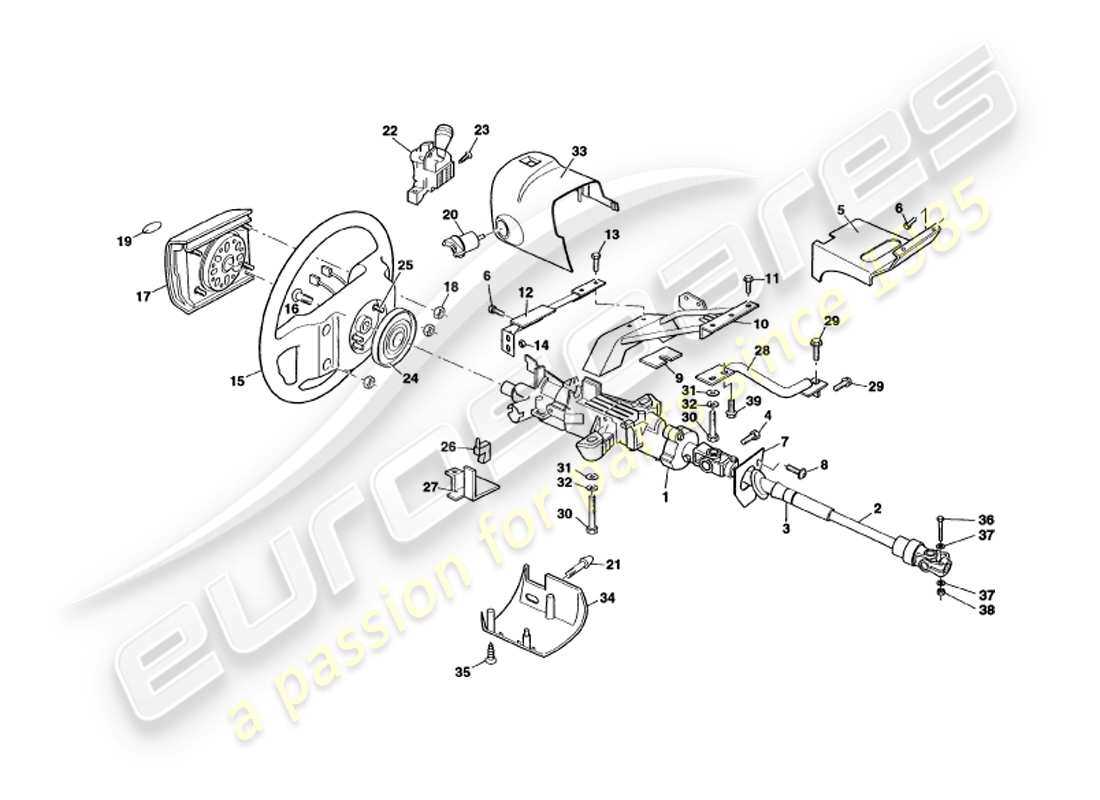

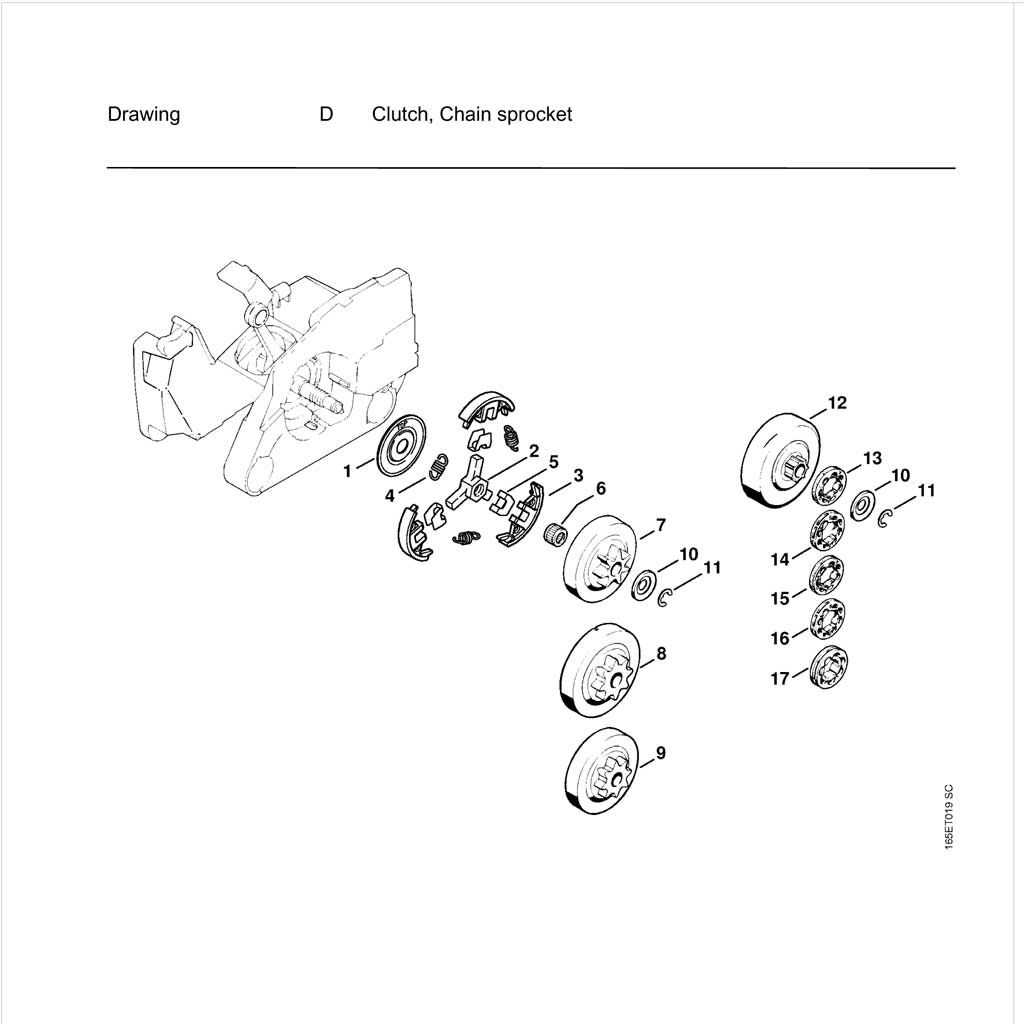

Understanding the layout of a machine’s components is crucial for effective maintenance and repair. A visual guide that illustrates the individual elements allows for a clear overview of their arrangement and interconnections. By mastering how to read such a guide, users can quickly identify the parts they need to inspect or replace.

Interpreting Symbols and Labels

Each component is typically represented by a symbol or illustration, accompanied by labels that provide additional details. These labels often include part numbers, which are essential for ordering replacements. Familiarity with these notations enables you to easily locate and identify specific items in the guide, ensuring you are addressing the correct components during repairs.

Following the Layout

The layout of a parts guide is often organized logically, with related elements grouped together. This structure helps you understand how the various components fit into the larger assembly. By tracing the flow from one part to another, you can gain a deeper understanding of the machine’s functionality, making it easier to pinpoint potential issues or improvements.

Common Issues and Part Replacements

Over time, any mechanical system may experience wear and tear, leading to issues that can impact performance. Recognizing common problems early is essential for preventing further damage and ensuring smooth operation. Knowing which elements are most likely to need replacement helps keep the machine running efficiently.

Engine Misfire and Fuel System Failures

One common issue is engine misfires, often caused by a malfunctioning spark plug or fuel system clog. A dirty or worn-out spark plug can prevent proper ignition, while a clogged fuel filter may restrict fuel flow, causing the engine to struggle or fail to start. Replacing these components regularly ensures the engine operates smoothly.

Airflow and Carburetor Problems

If the airflow is restricted due to a dirty air filter or malfunctioning carburetor, it can affect the engine’s performance. An air filter that’s clogged with dirt or debris can reduce airflow, leading to overheating or poor combustion. Similarly, a faulty carburetor may cause fuel mixture problems, resulting in inefficient fuel usage or stalling. Replacing these parts can restore normal function and prevent more serious issues.