Understanding the layout and function of the various elements within a chainsaw is essential for anyone performing maintenance or repairs. Knowing the arrangement of individual parts helps ensure that everything operates smoothly, avoiding costly mistakes or misdiagnoses of issues.

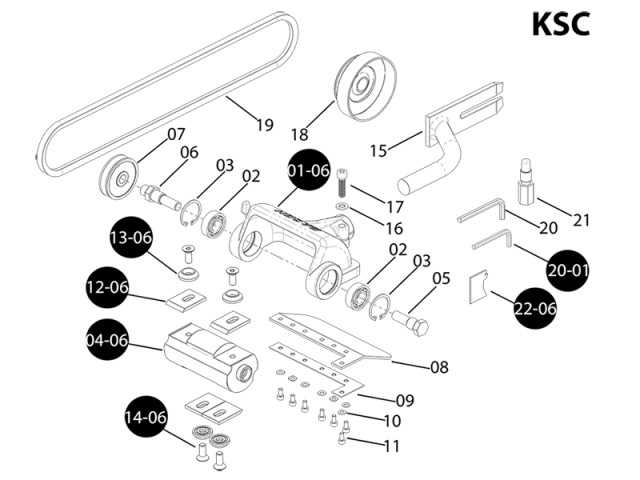

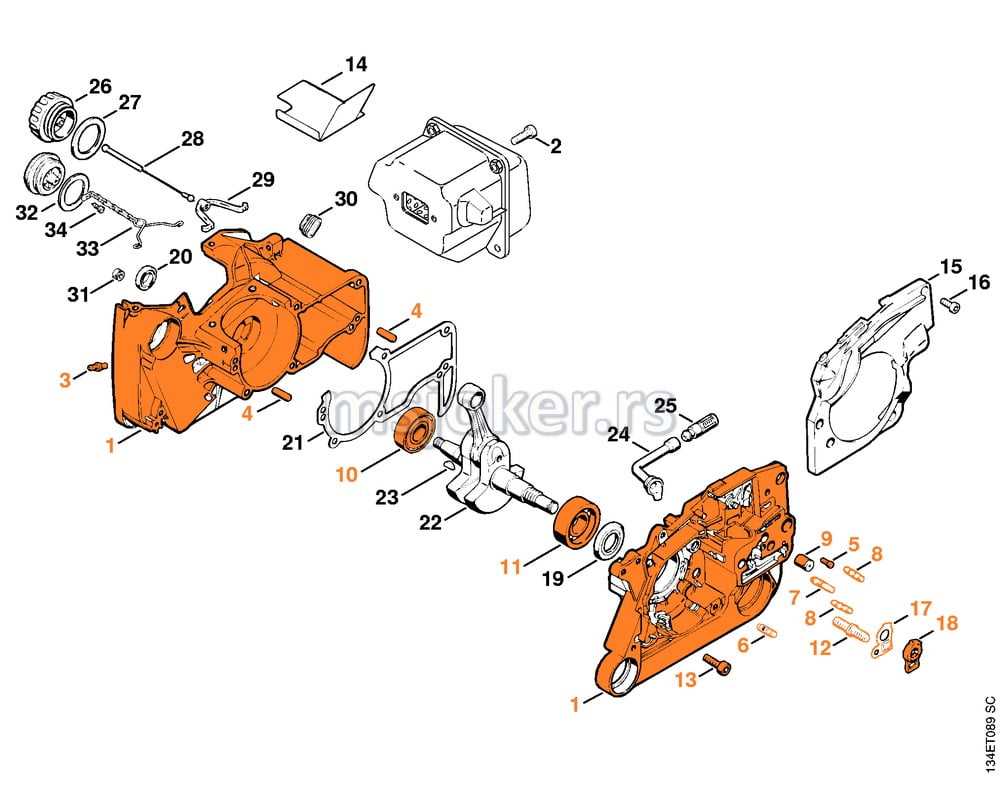

Proper identification of each component allows users to recognize when a replacement or adjustment is necessary. This guide will provide a clear visual breakdown, simplifying the process of troubleshooting and part replacement.

By mastering the structure and placement of key elements, users can extend the life of their equipment, improve performance, and reduce the frequency of repairs. With detailed illustrations, the process becomes straightforward and accessible for all skill levels.

Understanding Stihl 064 Parts Diagram

In order to perform efficient maintenance and repair work on your chainsaw, it’s important to have a clear understanding of its internal components and their layout. The visual guide of a tool’s assembly helps in identifying each element and its function, streamlining the process of troubleshooting and part replacement.

How Components are Organized

The various sections of the tool are grouped based on their functionality, such as the engine, ignition system, and drive mechanism. Each area is carefully arranged to ensure smooth operation and easy access during repairs. Recognizing how the parts fit together allows for a more effective approach when disassembling or reassembling the tool.

Benefits of Using a Visual Reference

Having a visual reference to locate and identify individual components can save time and prevent errors. With the right understanding, users can quickly pinpoint issues, select appropriate replacements, and avoid unnecessary disassembly. This methodical approach reduces downtime and increases the overall lifespan of the equipment.

Identifying Key Components of Stihl 064

Accurate identification of the primary elements within your chainsaw is essential for proper operation and maintenance. By recognizing the function and placement of each significant part, users can easily troubleshoot, replace, or adjust them as necessary, ensuring smooth performance.

Understanding Engine and Power Mechanism

The engine is the heart of the tool, driving all other components. Understanding its structure and how it interacts with other systems, such as the fuel and air intake, helps in diagnosing issues related to power loss or starting problems. A well-maintained engine contributes to overall efficiency and longevity.

Recognizing the Safety Features

Safety features are critical for preventing accidents during operation. Identifying elements such as the chain brake, throttle lock, and protective covers is vital for ensuring that the chainsaw operates within safe parameters. Regular checks of these components minimize risks during use.

How to Use the Parts Diagram Effectively

Using a visual representation of the tool’s components can significantly simplify maintenance tasks. By referring to a clear and detailed guide, users can identify specific parts and understand how they interconnect, which enhances the repair and assembly process.

Step-by-Step Approach

Begin by studying the layout carefully to familiarize yourself with the positioning of the key elements. Identify any areas of concern or parts that need replacement. This systematic approach helps avoid confusion and ensures that no critical components are overlooked.

Maximizing the Utility of the Visual Guide

To get the most out of a visual reference, keep it accessible during disassembly and assembly. Cross-reference the guide while working to confirm that all pieces are correctly placed. This will reduce the risk of errors and make the process more efficient.