Every chainsaw enthusiast knows that proper upkeep is essential for smooth operation and longevity. Having a clear understanding of the individual elements that make up the tool can significantly improve maintenance and repair processes. By recognizing and identifying each component, users can avoid unnecessary repairs and replace worn-out parts with ease.

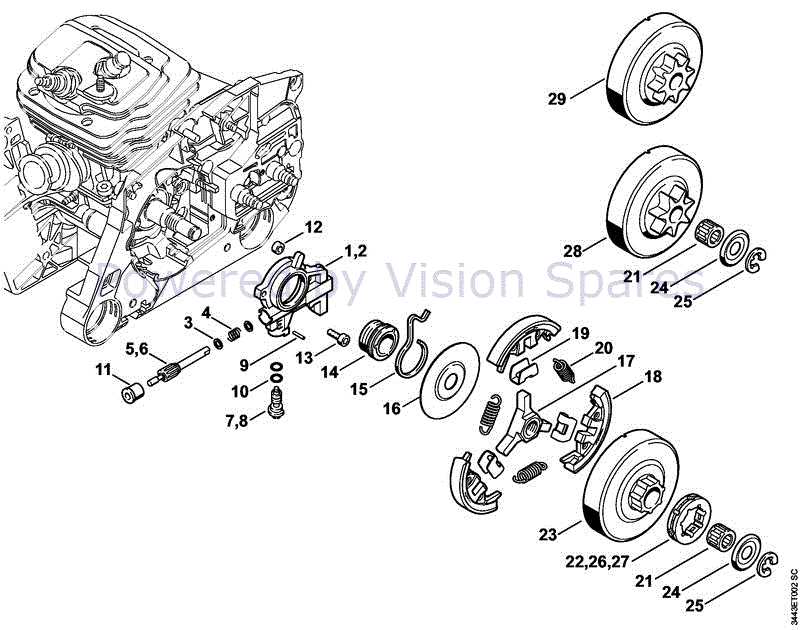

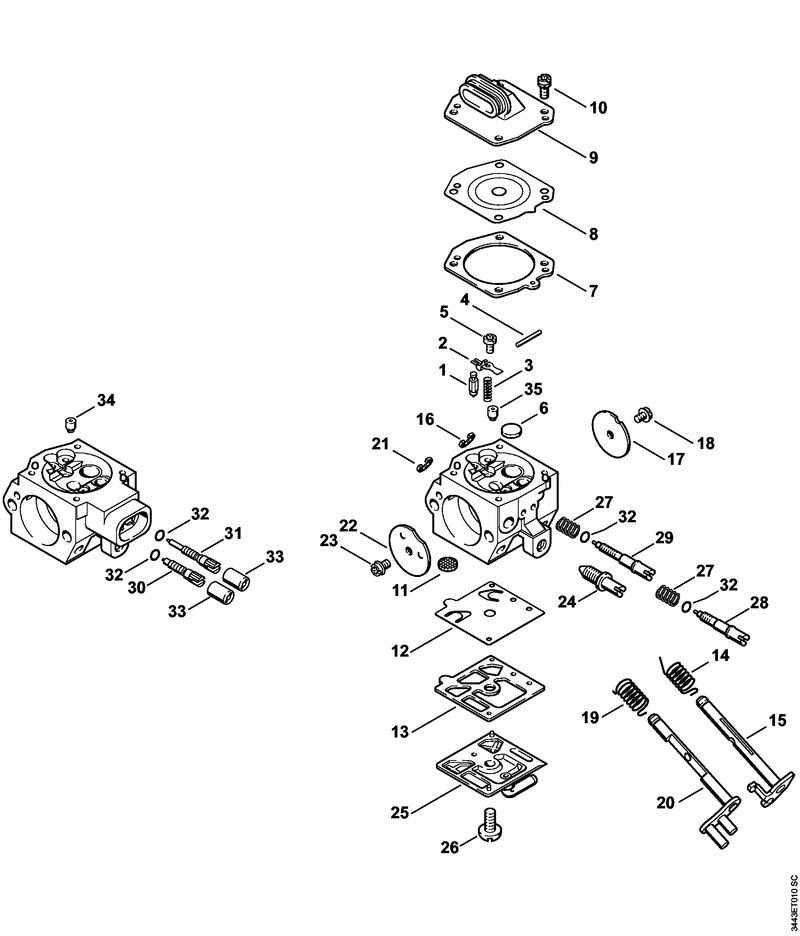

Using a detailed visual reference guide is an effective way to locate each part in your equipment. These guides offer a clear view of where each piece fits into the whole machine, allowing you to troubleshoot problems and ensure that everything is functioning as it should. Regular maintenance, informed by such resources, can save both time and money in the long run.

For those who wish to perform repairs or replacements on their own, having access to a complete overview of the tool’s build is invaluable. Whether you’re a professional or a hobbyist, understanding the internal structure will boost your confidence and help you make the right choices when parts need to be replaced.

Understanding Chainsaw Component Layout

Every machine consists of various components that work together to ensure smooth functionality. Familiarizing yourself with the arrangement and function of these elements helps in performing accurate maintenance and repairs. A detailed layout of your equipment provides a comprehensive understanding of how each part interacts within the system.

When you refer to a detailed illustration of your tool’s configuration, you can pinpoint the exact location of every piece. This layout serves as a roadmap for identifying worn-out or damaged components, making it easier to troubleshoot and replace specific sections. With this knowledge, users can carry out repairs effectively without unnecessary confusion.

Moreover, understanding the structure allows you to assemble, disassemble, and reassemble your tool with confidence. Recognizing how individual components fit together ensures that you don’t miss any crucial steps during the maintenance process, improving the overall efficiency of your work.

How to Identify Chainsaw Components

Recognizing individual components of your chainsaw is essential for effective maintenance and repair. By learning to identify each part, you can quickly assess issues and replace specific pieces without confusion. A clear understanding of your tool’s elements can significantly enhance its performance and extend its lifespan.

Visual Inspection

Start by conducting a thorough visual inspection of the machine. Most parts have distinctive shapes and sizes that help in identification. Look for labels or numbers printed on the components, which often indicate the part’s function or model. A keen eye will help you spot worn-out or damaged pieces that need attention.

Consulting Reference Materials

Using manuals or online guides provides a more structured approach to identifying parts. These resources often feature labeled images and descriptions, making it easier to correlate each part with its function. This approach is especially helpful when you’re unfamiliar with certain components and want to be precise in your identification.

Maintaining Your Chainsaw with Accurate Guides

Proper maintenance of your chainsaw requires a detailed understanding of its internal components and how they interact. Accurate reference materials are invaluable in ensuring that every part is properly maintained, allowing you to perform necessary repairs or replacements with confidence. With the right guide, you can maintain the machine’s efficiency and prevent costly issues in the future.

Following Clear Maintenance Instructions

One of the key benefits of using a reliable guide is the ability to follow clear, step-by-step instructions for maintenance tasks. Whether you’re cleaning, lubricating, or replacing parts, having an accurate reference helps you avoid mistakes and ensures the tool continues to perform at its best.

Visualizing Component Placement and Alignment

A well-structured guide allows you to see where each component fits within the machine and how they align with one another. This visualization helps in the disassembly and reassembly process, ensuring that all parts are correctly positioned to avoid operational issues or damage during maintenance.