When it comes to keeping your outdoor equipment in top condition, knowing the internal structure is crucial. Each tool has its own set of essential components, each serving a specific function to ensure smooth operation. Understanding how these elements work together can significantly improve your maintenance efforts and help you troubleshoot issues more effectively.

Proper knowledge of the internal layout is essential when performing repairs or upgrades. Whether you’re replacing a worn-out piece or conducting regular upkeep, having a clear understanding of what each component does will save time and effort. With the right tools and a clear view of the internal mechanics, maintaining your equipment becomes much more manageable.

By familiarizing yourself with the assembly of your tool, you can better anticipate potential issues and address them promptly, extending the overall lifespan of your equipment. Proper care is not just about fixing problems when they arise but preventing them from happening in the first place. This section will guide you through the necessary components for proper handling and maintenance.

Understanding Stihl BG 86 Components

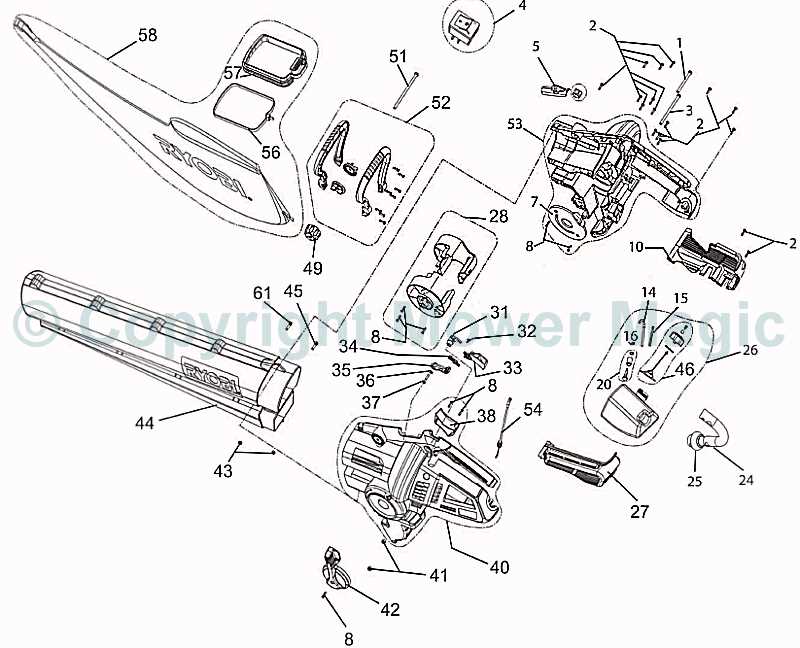

To maintain any outdoor tool effectively, it’s essential to understand how its components function together. Each element of the equipment has a specific role that contributes to its overall performance. Identifying and knowing the purpose of each part will not only help in repairs but also in ensuring smooth operation during use.

Main Functional Elements

The key components of this equipment are designed to work in harmony. From the engine to the air intake system, each piece plays a crucial role in how the tool performs. The internal engine components, such as the carburetor and spark plug, work together to generate power and ensure consistent performance. Meanwhile, the intake and exhaust systems manage airflow to maximize efficiency and minimize wear.

Supportive Mechanisms

In addition to the core functional parts, several supporting elements are also vital to the tool’s smooth operation. These include the handle, trigger mechanism, and safety features, all of which ensure user control and safety. The ergonomic design of the handle allows for better maneuverability, while the safety features provide peace of mind when operating the tool for extended periods.

Repairing Your Stihl BG 86 Blower

When your outdoor equipment starts malfunctioning, timely repairs can restore it to full functionality. Understanding how to troubleshoot and address common issues is essential for keeping the tool running smoothly. By learning basic repair techniques, you can save time and money while ensuring the longevity of your equipment.

Identifying Common Issues

Before starting any repair, it’s important to identify the problem. Common issues with this equipment typically involve fuel system malfunctions, airflow restrictions, or engine performance issues. A clogged air filter or a malfunctioning carburetor can prevent the tool from starting properly or cause it to lose power. Regularly checking these components can help pinpoint the source of the problem.

Performing Simple Repairs

Once the issue is identified, performing basic repairs can often be done without professional assistance. For example, replacing a clogged filter or cleaning the spark plug is a simple task that can be done in a short amount of time. If the fuel system is the culprit, draining and replacing old fuel or adjusting the carburetor may restore the equipment’s function. Regular maintenance is key to avoiding more serious issues down the line.

Essential Tools for BG 86 Maintenance

Proper maintenance of your equipment requires the right set of tools to ensure everything runs efficiently. Whether it’s cleaning the engine, replacing filters, or tightening components, having the right instruments on hand is crucial for both performance and longevity. Using quality tools can make maintenance tasks easier and more effective.

Basic Maintenance Tools

Some of the most commonly used tools include a screwdriver set, pliers, and a wrench. These tools allow you to access and adjust various parts of your equipment. Regular cleaning of components like the air filter and spark plug often requires a small brush or compressed air to remove dirt and debris. Having a set of replacement screws and bolts is also useful in case any become loose or damaged during use.

Advanced Repair Tools

For more advanced repairs, tools such as a spark plug socket and a carburetor cleaning kit are essential. These allow you to address issues with engine performance and fuel delivery. Additionally, a fuel line replacement tool can help you maintain the fuel system, ensuring that no leaks or blockages affect the tool’s operation. Having these specialized tools at your disposal will make more complex repairs much more manageable.