Understanding the structure of a device is essential for efficient upkeep and repairs. A clear visual representation helps locate individual elements and assess their function within the system.

A well-organized schematic allows users to quickly identify necessary replacements. Knowing how each section connects ensures smooth operation and prevents unexpected failures.

Regular inspection and proper handling extend the lifespan of any machine. Following a structured approach to servicing minimizes wear and enhances overall performance.

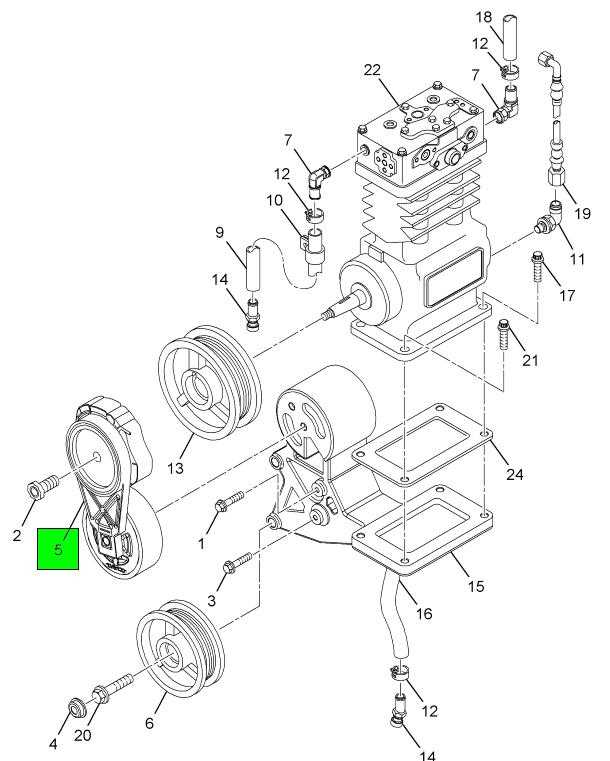

Component Overview and Assembly Guide

Every mechanical system consists of interconnected elements that ensure smooth functionality. A well-structured layout helps users understand how different sections interact and simplifies maintenance.

Key Structural Elements

The main framework provides stability and houses essential components responsible for operation. Various connectors, fasteners, and seals secure the internal mechanisms, preventing wear and ensuring durability.

Efficient Assembly and Maintenance

Properly aligning each section during setup enhances efficiency and reduces strain on individual elements. Routine inspections help detect potential issues early, allowing timely replacements and adjustments for long-term reliability.

Understanding the Components Layout

Every mechanical system is built from multiple interconnected elements, each serving a specific function. A clear arrangement of these sections ensures smooth operation, easy troubleshooting, and efficient servicing.

- Power Unit: Generates the necessary force to drive the entire mechanism, ensuring optimal performance.

- Airflow System: Regulates ventilation, preventing overheating and maintaining efficiency during operation.

- Control Mechanism: Includes levers, switches, and triggers that allow precise adjustments and user control.

- Support Frame: Provides structural integrity and stability, ensuring durability under continuous use.

Understanding how these elements connect allows for quick identification of potential issues and simplifies routine upkeep. Proper positioning of each section prevents unnecessary wear and enhances longevity.

- Regularly check all connections to ensure stability and proper alignment.

- Inspect moving elements for signs of friction or obstruction.

- Keep ventilation passages clear to avoid overheating and performance drops.

- Verify fasteners and seals to prevent unwanted vibrations or leaks.

A well-maintained layout improves efficiency and extends the operational life of the system. Familiarity with each section allows for quick adjustments and timely replacements when needed.

How to Identify Replacement Components

Recognizing worn-out or damaged elements is essential for maintaining efficiency. Knowing how to find suitable substitutes ensures smooth functionality and prevents unexpected breakdowns.

Assessing Wear and Damage

Regular inspections help detect issues before they escalate. Look for visible cracks, excessive friction marks, or loose connections that may affect performance. Unusual noises, reduced efficiency, or inconsistent operation often indicate the need for replacements.

Matching the Right Substitute

To ensure compatibility, check for model-specific identifiers such as serial numbers, dimensions, and material composition. Comparing the shape and attachment points with an original reference helps avoid installation errors.

Keeping track of frequently replaced elements and sourcing high-quality alternatives extends the lifespan of the entire system. Proper selection and timely updates contribute to long-term reliability and optimal performance.

Maintenance Tips for Longevity

Consistent upkeep ensures reliable performance and extends the lifespan of any equipment. Proper handling, routine inspections, and timely adjustments help prevent unexpected failures and costly repairs.

Keep all components clean to avoid debris buildup that can hinder functionality. Regularly remove dust, dirt, and residue from critical areas to maintain efficiency.

Lubricate moving sections to reduce friction and wear. Using the correct type of oil or grease enhances smooth operation and prevents overheating.

Inspect fasteners and seals to ensure stability and prevent leaks. Loose connections can lead to misalignment, causing unnecessary strain on the system.

Store in a dry, protected area to prevent corrosion and material degradation. Exposure to moisture or extreme temperatures can weaken structural integrity over time.

By following these simple steps, you can maintain peak performance and ensure long-term durability, reducing the need for frequent replacements.