Maintaining your equipment requires a clear understanding of its individual components. Whether you’re replacing a worn-out piece or conducting a routine check, knowing how each part functions is crucial for smooth operation. This guide will help you identify key sections of your tool and provide useful information for efficient maintenance.

Knowing the layout of your device allows for quicker repairs and ensures that all components are in proper working condition. By focusing on specific sections, you’ll gain confidence in diagnosing issues and making replacements when necessary.

Proper maintenance not only extends the lifespan of your tool but also ensures its performance is optimized. In this article, we’ll cover the essential parts and provide helpful tips for anyone looking to get the most out of their equipment.

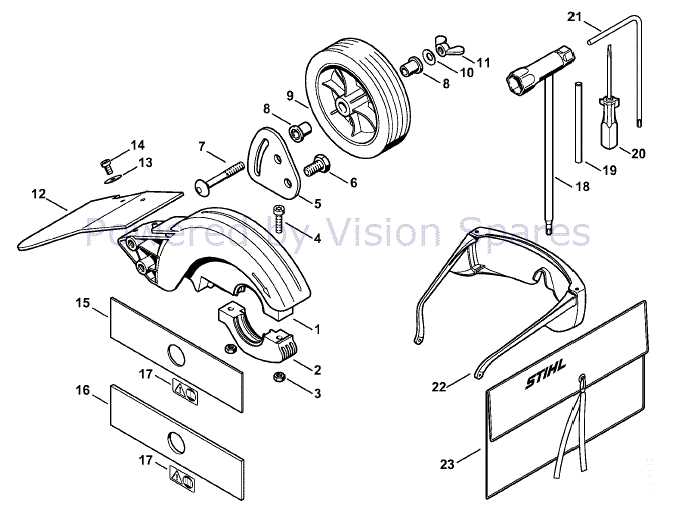

Stihl FC 70 Edger Parts Overview

Understanding the key components of your tool is essential for effective maintenance and repair. Each piece plays a specific role in ensuring smooth operation, and recognizing them can help you identify any issues quickly. This section will provide an overview of the critical elements that make up your equipment, highlighting their functions and how they contribute to overall performance.

The primary sections consist of the power unit, cutting mechanism, and safety features. Each of these parts must be in good condition to ensure the tool runs efficiently. Whether you’re dealing with engine components or structural elements, a clear understanding of these parts will make maintenance tasks easier and more effective.

By familiarizing yourself with the layout and functions of the different sections, you’ll be better equipped to troubleshoot problems and perform necessary replacements. This knowledge is key to keeping your equipment running at its best for years to come.

How to Identify Edger Components

Properly identifying the different elements of your tool is essential for maintenance and troubleshooting. Each component serves a unique purpose, and recognizing them can help you address any issues more efficiently. In this section, we’ll guide you through the process of identifying the key parts of your equipment, making it easier to manage repairs and upgrades.

The first step is to familiarize yourself with the basic structure of the tool. Start with the main housing, which houses the engine or motor, and identify the key moving parts like the cutting mechanism and drive shaft. Then, take note of the support structures and safety features, which play a vital role in the overall performance and safety of the tool.

Understanding the function of each section will make it easier to troubleshoot issues. Whether you are replacing a worn-out part or simply conducting routine maintenance, knowing what each component does will save you time and effort in the long run.

Common Issues with Stihl FC 70 Parts

Like any mechanical tool, your equipment may face certain challenges over time. Identifying these issues early on is crucial for preventing more severe damage. This section covers the most common problems users encounter with various components, helping you to troubleshoot and maintain your device effectively.

Some frequent issues include:

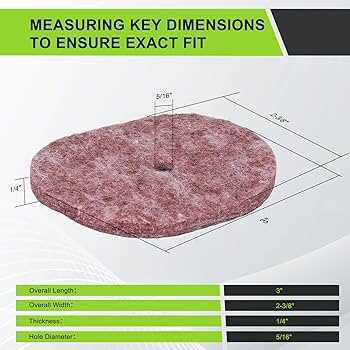

- Worn-out cutting components – Over time, blades or cutting discs can become dull or damaged, affecting performance.

- Engine problems – Issues such as starting trouble or power loss may arise from fuel line blockages or spark plug malfunctions.

- Drive shaft issues – The drive shaft can wear down, causing loss of power transmission to the cutting components.

- Fuel system blockages – Clogged fuel filters or lines can lead to poor engine performance or difficulty starting.

- Handle or frame damage – Physical damage to the tool’s body can affect stability and user control.

By recognizing these common issues early, you can take proactive measures to replace or repair the affected components, ensuring the longevity and reliability of your equipment.