Every outdoor maintenance tool is made up of several intricate elements working together to ensure smooth and efficient operation. Understanding how each component fits into the larger system is essential for effective maintenance and troubleshooting. Familiarity with these parts can greatly improve your ability to repair or replace damaged components when necessary.

Visual aids are often the best way to break down complex mechanisms. They provide clarity on the specific location and function of each part, helping users identify issues quickly. By examining these visual representations, you can gain a deeper understanding of how the individual pieces interact and contribute to the overall performance of your equipment.

Whether you’re a seasoned user or just starting, knowing how to interpret these visual guides can save you time and effort. With the right knowledge, even minor repairs or part replacements become much easier, keeping your equipment running efficiently for years to come.

Understanding Stihl FC 91 Edger Components

To effectively operate and maintain your outdoor equipment, it’s essential to familiarize yourself with the key elements that contribute to its functionality. Each component plays a vital role in ensuring smooth performance, from the engine to the cutting mechanism. Recognizing how these parts work together allows you to keep your tool in optimal condition and address any issues that may arise.

Familiarity with the internal and external components helps when performing routine maintenance or troubleshooting. Knowing the specific function of each element aids in identifying areas that may require attention. Understanding the relationship between moving and stationary parts also allows for more precise repairs and part replacements.

When inspecting the tool, pay attention to critical areas such as the drive system, control handles, and power source. A well-maintained tool ensures reliability and longevity, making your outdoor tasks more efficient and hassle-free. With the right knowledge, you can confidently handle repairs and replacements to keep everything running smoothly.

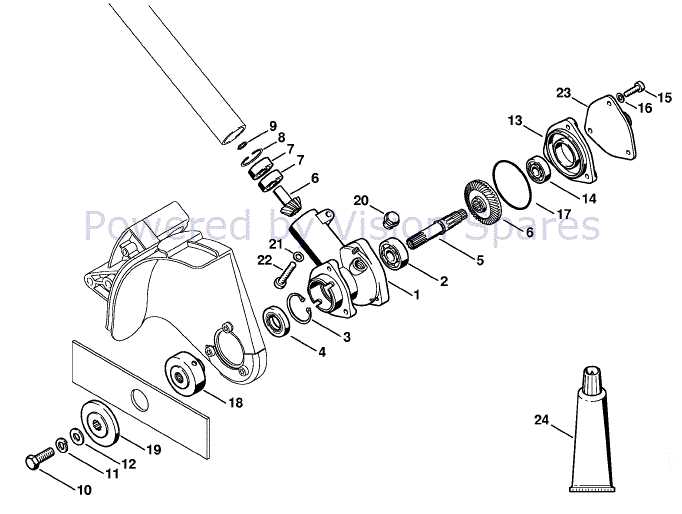

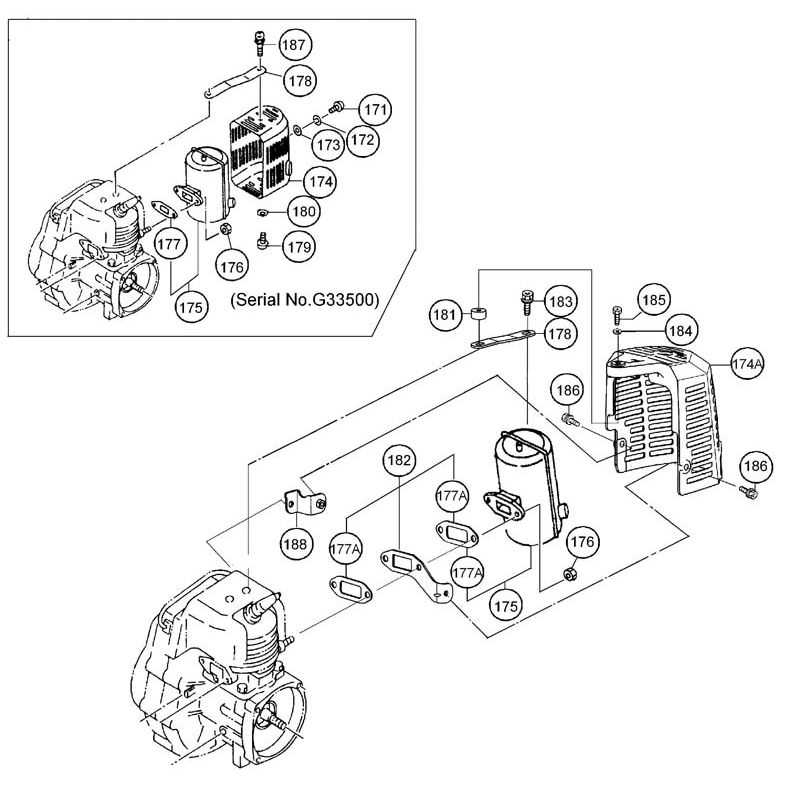

Identifying Key Parts in the Diagram

When working with any outdoor tool, knowing the main components and their functions is crucial. Visual representations can help pinpoint each part’s location and role within the overall system. By breaking down these illustrations, you gain the ability to quickly identify damaged or worn-out sections, making maintenance tasks more efficient.

Locating Critical Components

Start by focusing on the core elements, such as the power source, control mechanisms, and drive systems. These parts are essential for the tool’s functionality and are often the most prone to wear and tear. Understanding where each component is located in the visual guide helps you to troubleshoot issues faster.

Recognizing Secondary Parts

Secondary components, like supports, fasteners, and small attachments, also contribute to the tool’s overall performance. While these parts may not directly impact functionality, they are still important for structural integrity. Identifying these parts ensures you can replace or adjust them when needed, preserving the tool’s efficiency and longevity.

How to Use the Parts Diagram for Repairs

Understanding how to effectively use a visual guide for repairs is a valuable skill when maintaining your equipment. These guides break down the tool into its essential elements, showing you exactly where each component fits and how they interact with one another. By referring to this type of illustration, you can efficiently identify which parts need attention or replacement.

Start by locating the part that seems to be malfunctioning. Compare it with the corresponding section in the visual guide to understand its position and how it connects to other components. Once identified, you can easily determine if the part needs repair, adjustment, or replacement. This process ensures you make informed decisions when sourcing new components or carrying out fixes.

Using a clear and detailed guide also allows for better organization during repairs. With each part’s location mapped out, you can work systematically, saving time and avoiding unnecessary mistakes. Whether it’s tightening loose connections or replacing a worn-out part, the diagram ensures you follow the correct steps, resulting in a smoother and more efficient repair process.