Maintaining outdoor power equipment requires a clear understanding of its individual elements. Whether for routine upkeep or repair, knowing how each component fits together ensures efficient operation and longevity. Proper identification and replacement of parts can help keep your tool running smoothly and prevent unnecessary damage.

In this guide, we will explore the critical components of a specific tool, providing a clear overview of how each piece works within the system. With the right knowledge, you can easily identify issues and perform essential fixes, ensuring your equipment remains in top condition.

Understanding the layout and function of these pieces is essential for anyone who wishes to maintain their tool effectively. This detailed guide will help you navigate the process of troubleshooting and replacing necessary components, ensuring optimal performance at all times.

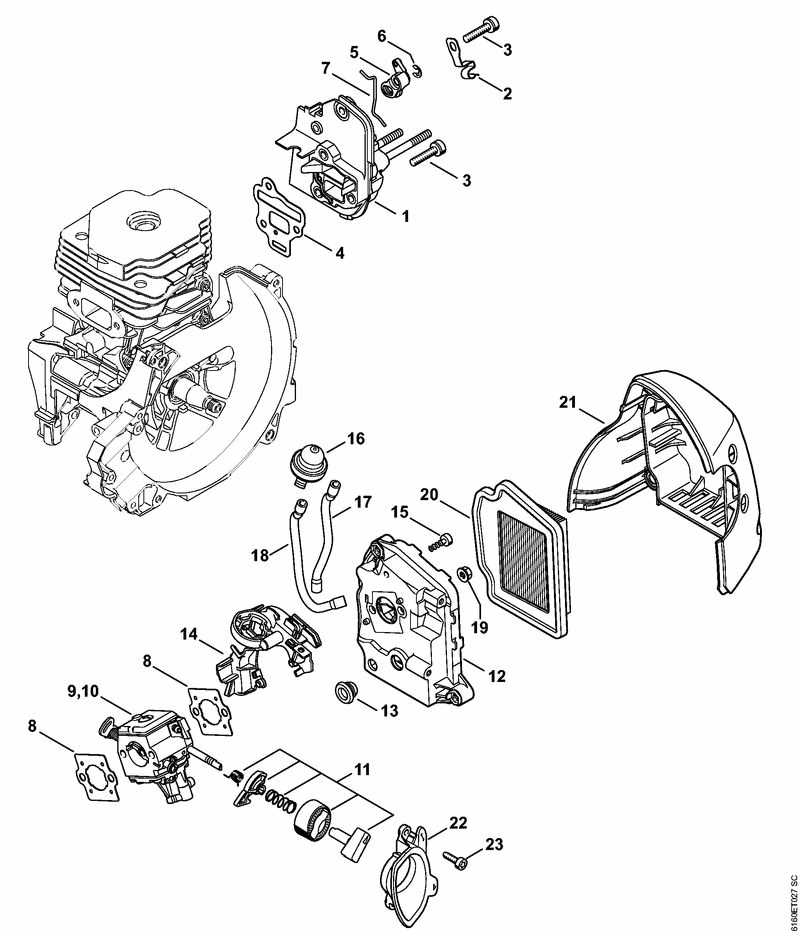

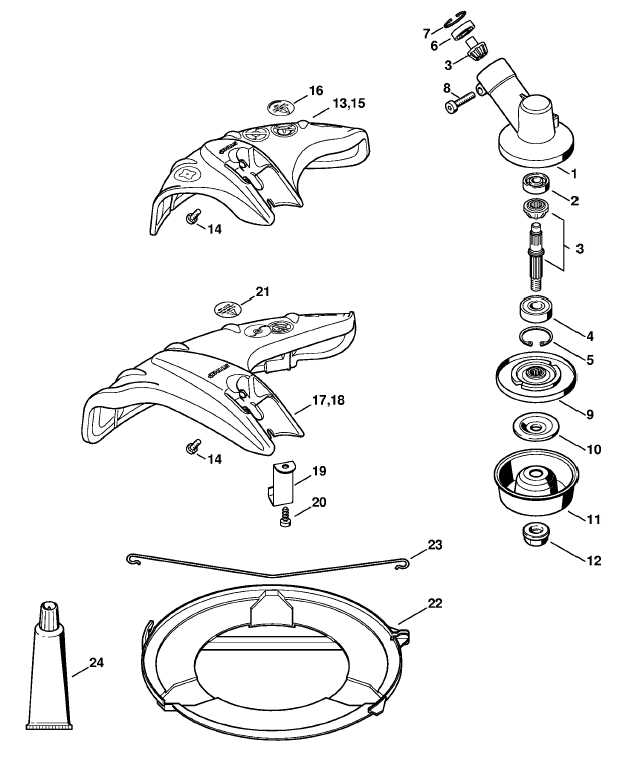

Understanding the Tool Components Layout

Every outdoor power tool is made up of various interconnected elements that work together to ensure proper functionality. Understanding how these components interact is key to both routine maintenance and troubleshooting. A clear knowledge of the layout allows you to pinpoint issues and address them efficiently without unnecessary disassembly.

In this section, we will break down the essential elements of the equipment, outlining their placement and role in the overall operation. By becoming familiar with the tool’s structure, you can improve your ability to carry out repairs and make informed decisions about replacements when necessary.

Recognizing the position and function of each component is crucial for anyone looking to maintain the tool. With this understanding, you can approach any maintenance tasks with confidence, ensuring that each part is in its correct place and functions as intended. This layout overview simplifies the process of identifying problems and guides you through efficient repairs.

Essential Components for Tool Maintenance

To keep any outdoor power equipment running smoothly, it is vital to focus on the key components that require regular care. These critical elements ensure optimal performance and help avoid costly repairs down the line. Understanding what each part does and when it needs attention can significantly extend the life of the tool.

Routine maintenance involves checking and replacing worn-out pieces, lubricating moving parts, and ensuring that all elements are aligned and functioning correctly. Whether you’re dealing with the engine, cutting mechanism, or other internal systems, each component plays a vital role in the overall efficiency of the equipment.

By prioritizing maintenance on the most essential elements, you can address issues before they affect performance. Regular inspection and care of these parts will lead to more reliable use and fewer unexpected malfunctions, ensuring the tool performs effectively for an extended period.

How to Identify Tool Replacement Components

When it comes to repairing outdoor equipment, knowing how to identify the correct replacement elements is crucial for a successful fix. Whether you need to replace a worn-out part or perform an upgrade, understanding which components are compatible ensures your tool continues to operate effectively. This process involves examining the tool’s function, structure, and the specific role each part plays within the system.

To accurately identify the components that need replacement, follow these steps:

- Consult the manual: Most tools come with a detailed guide that includes information on the essential elements, their part numbers, and any specific models they fit.

- Examine the damaged part: Look for part numbers or identifiers on the damaged piece. Many components have labels or stamps that make identification easier.

- Use online resources: Manufacturers’ websites and trusted repair sites provide exploded views and parts lists for tools, which can help you locate the part you need.

- Visit a local dealer: Authorized dealers or service centers can help you identify the correct replacement and offer advice on the best options available.

By following these steps, you can confidently identify and order the right replacement pieces for your tool, ensuring smooth operation and longevity.