Proper understanding of the inner workings of your equipment is crucial for keeping it running smoothly. Knowing how all the components fit together allows you to troubleshoot issues effectively and maintain peak performance. This guide will help you gain insight into the essential elements of the machine, ensuring that you can identify problems quickly and make necessary adjustments.

Efficient maintenance begins with a clear understanding of the structure and functionality of the key elements. Whether you are replacing a worn-out part or simply performing routine checks, having a reference point will make the process easier and more precise. This article breaks down the important features, offering you a valuable tool for upkeep.

By familiarizing yourself with the configuration, you can avoid unnecessary repairs and extend the life of your equipment. Accurate identification of components not only prevents errors but also saves you time and money, allowing for seamless operation over the long term.

Understanding Key Components

Every piece of equipment relies on a combination of critical elements working in harmony. These essential parts contribute to the overall performance and reliability, each serving a specific function that enhances efficiency. Gaining a clear understanding of these components is crucial for effective maintenance and troubleshooting, as well as ensuring optimal operation over time.

The central mechanism includes the motor, drive system, and various accessories that allow for smooth functionality. Knowing how these elements interact and the role each plays can significantly reduce the likelihood of malfunctions and simplify the repair process. Familiarity with the configuration will empower you to address issues quickly and accurately.

Additionally, some components are designed for easy replacement, enabling you to extend the life of the equipment with minimal effort. Regular checks and proper identification of wear and tear will ensure that the machine continues to operate at its best, preventing costly repairs and downtime.

How to Read the Parts Diagram

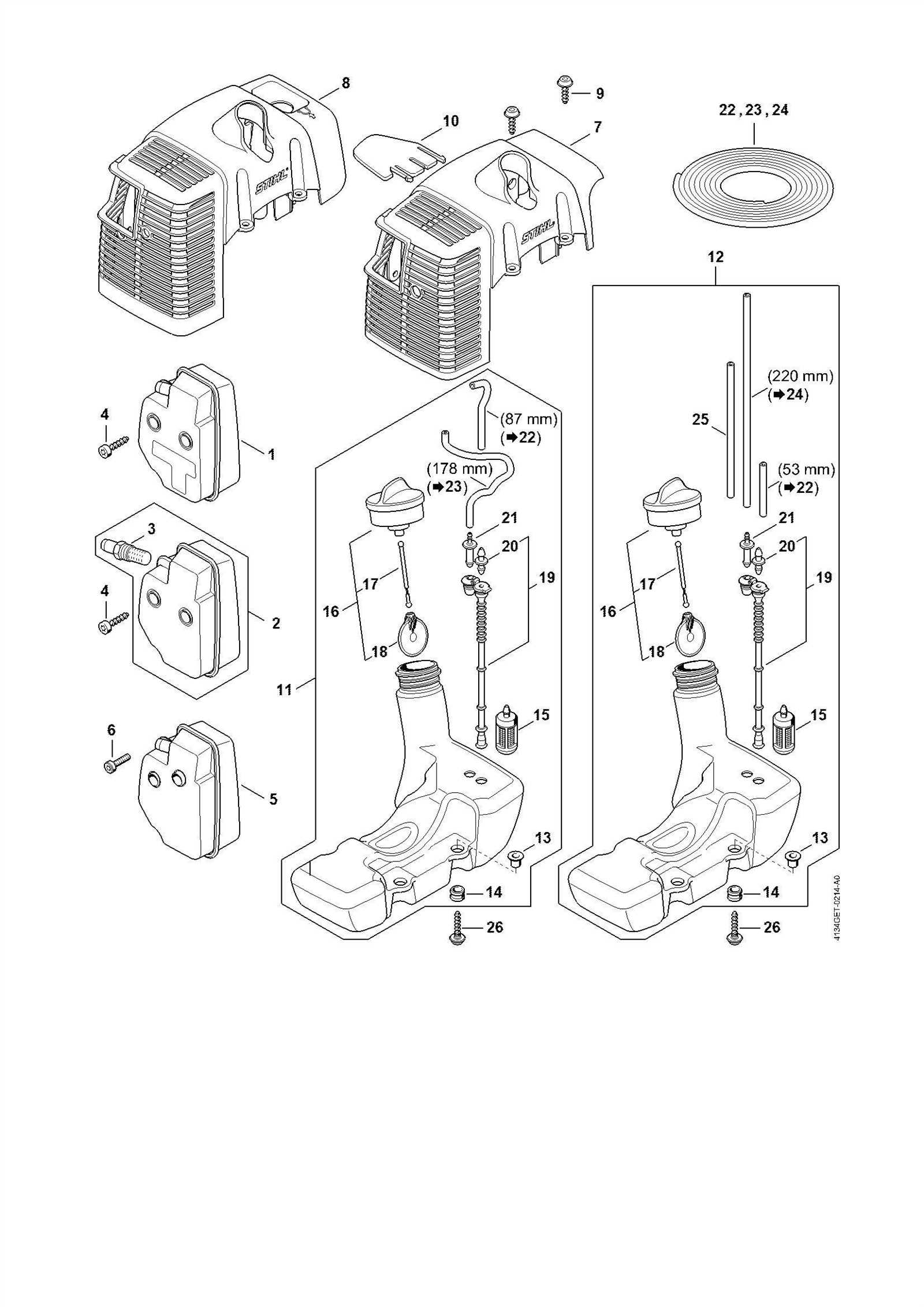

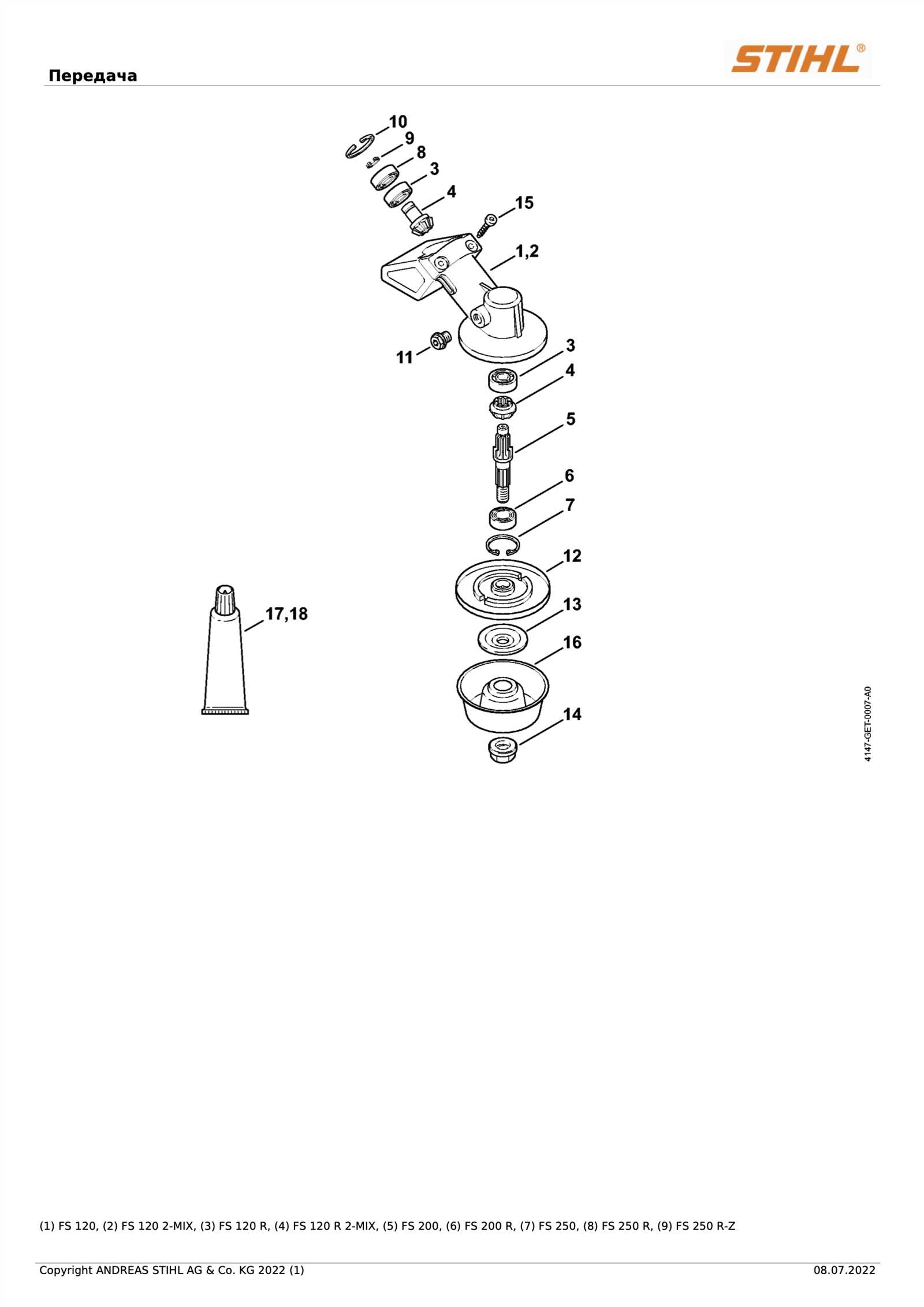

Understanding the visual representation of a machine’s components is crucial for proper maintenance and repair. These illustrations provide a detailed view of how the various parts fit together and how they function within the system. Learning how to interpret these diagrams will make identifying issues and selecting replacement items much easier.

Key Elements in the Diagram

The diagram typically shows a layout of the major components, often numbered or labeled for easy identification. Understanding these labels and their relationships to one another will allow you to navigate the illustration efficiently. Pay attention to the connections between elements to see how each part contributes to the overall performance.

Interpreting Labels and Notations

In addition to the visual layout, diagrams often include specific notations or references that offer more information about the components. These might include part numbers, sizes, or material specifications. Recognizing these details is essential for ensuring that the correct replacement or repair is made, preventing mistakes in future servicing.

Identifying Common Replacement Parts

When it comes to maintaining your equipment, it’s important to recognize the most commonly replaced components. Some parts experience wear and tear more frequently, requiring regular attention to ensure optimal performance. Knowing which elements to monitor and replace can help prevent major breakdowns and keep your tool functioning smoothly.

Commonly Replaced Elements

Components such as the cutting head, air filter, and fuel lines often need replacement due to regular use. Cutting mechanisms can dull over time, while filters may clog, reducing efficiency. Keeping track of these high-use items ensures that you address potential problems early before they affect the machine’s overall functionality.

Signs of Wear and How to Spot Them

Look for signs like unusual noise, reduced performance, or visible damage to the equipment. If certain parts become damaged or worn out, replacing them promptly with the correct alternatives can save you from more costly repairs down the road. Regular inspection is key to identifying parts that need attention.