Proper maintenance of your lawn equipment is essential for its longevity and performance. Understanding the inner workings and components of your device is the first step toward effective repairs and upkeep. A clear reference to the different parts and their connections will make troubleshooting easier and help you avoid costly mistakes.

Whether you’re a beginner or an experienced user, having a reliable guide to assist in identifying and assembling the crucial elements of your trimmer can save you both time and effort. This guide is designed to give you a detailed overview of the key components involved in maintaining your tool, ensuring it runs smoothly for longer periods.

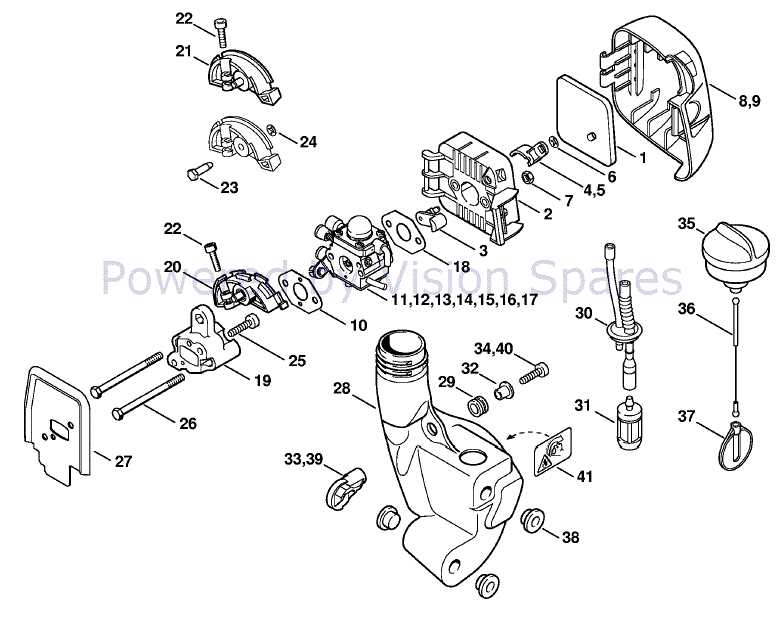

Understanding FS 38 Components

Knowing the individual components of your lawn tool is crucial for proper handling and maintenance. Each element plays a specific role in ensuring the device operates efficiently, and understanding their functions helps in troubleshooting and repair. By familiarizing yourself with the setup and layout, you’ll be better equipped to identify any wear or damage that may occur over time.

From the engine to the cutting mechanism, each segment contributes to the overall performance. Familiarity with how these parts interact and the general assembly process ensures that you can quickly assess any issues that arise. This section will provide a detailed look at the essential components of your tool and their roles in its functionality.

How to Use the Component Layout

Utilizing a clear visual reference of your equipment’s structure is essential for quick and efficient repairs. This guide helps you understand how to read and interpret the visual representation of the tool’s build, showing where each individual element fits into the overall system. With this knowledge, identifying and replacing damaged parts becomes straightforward.

Start by locating the specific component you need to address. The visual representation will often highlight the corresponding areas and provide a clear indication of how they connect to other parts. By following these visual cues, you can disassemble, inspect, and reassemble your tool with ease, ensuring all components are in the correct place for optimal performance.

Common Issues and Solutions for FS 38

Even the most reliable equipment can encounter problems over time. Understanding the most common issues and knowing how to address them can save you time and money. Below are several typical problems that may arise with your tool and the corresponding solutions to keep it running smoothly.

Fuel System Problems

A malfunctioning fuel system is one of the most common issues. If your tool is having trouble starting or the engine cuts off unexpectedly, the fuel components might be the culprit. Here are some potential causes and fixes:

- Clogged fuel filter – Replace the filter to ensure proper fuel flow.

- Old or contaminated fuel – Use fresh fuel and clean the fuel tank to prevent engine stalling.

- Air filter issues – Check and clean the air filter regularly to avoid poor combustion.

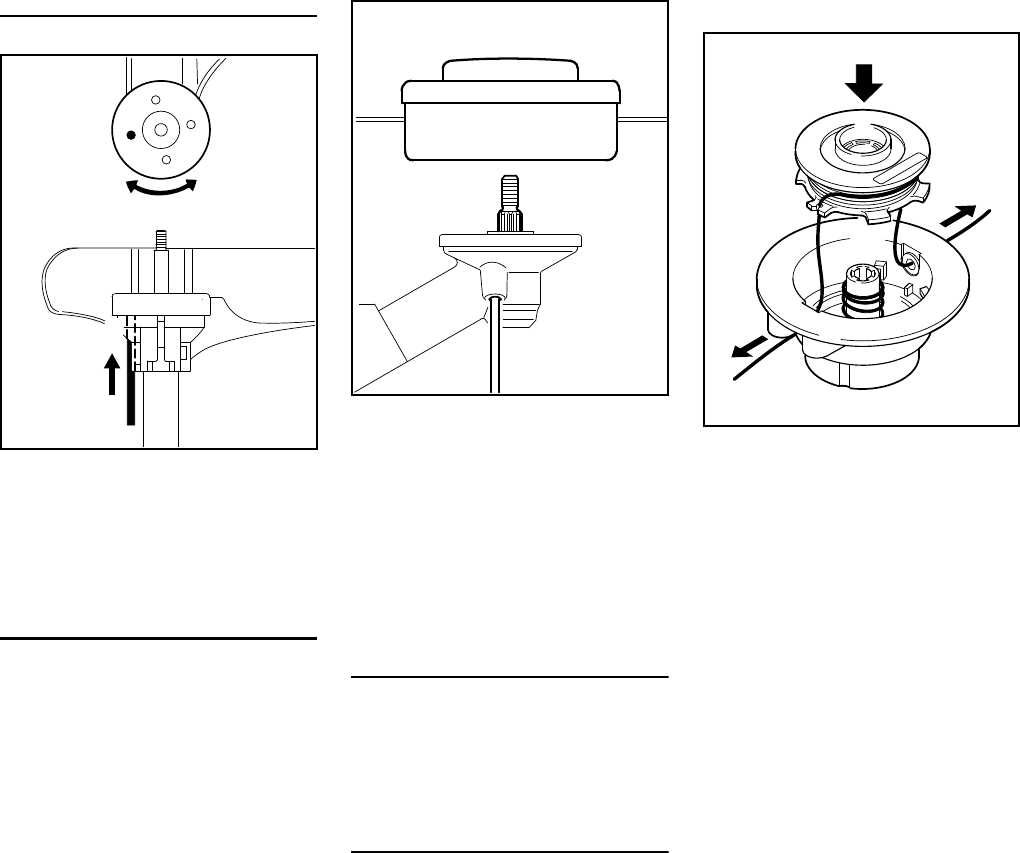

Cutting Mechanism Problems

If the cutting mechanism is not functioning correctly, your device may fail to trim effectively. Below are some tips to troubleshoot:

- Worn-out cutting blade – Inspect the blade for any damage or wear and replace it if necessary.

- Incorrect line installation – Make sure the line is properly wound and tensioned on the spool for optimal cutting.

- Obstructions – Clear any debris or objects that may be blocking the cutting path.