Maintaining and repairing lawn care tools can seem challenging without a clear understanding of their components. To make the process easier, having a visual guide that highlights each part’s position and function is invaluable. This type of reference helps users identify and replace specific pieces efficiently.

Knowing how your equipment is assembled allows you to troubleshoot issues, perform necessary repairs, and ensure smooth operation. By following a detailed reference, it becomes easier to spot wear and tear, replace worn-out elements, and extend the lifespan of your device.

Proper maintenance can save both time and money in the long run. Whether you’re performing a routine check-up or fixing a malfunction, having a clear breakdown of your tool’s internal structure aids in achieving optimal results.

Understanding Your Lawn Tool Components

When it comes to lawn care equipment, each element plays a specific role in ensuring smooth operation. Having a clear understanding of how these elements fit together can significantly ease maintenance and repairs. Whether you are replacing a damaged component or performing routine upkeep, recognizing each part’s function is essential for optimal performance.

Key Components to Focus On

The core of any lawn care device includes a variety of components that work together. From the motor housing to the cutting mechanism, each section is designed to perform a specific task. Recognizing these parts helps in identifying common issues such as poor performance or breakdowns.

Maintenance Tips for Longevity

Regular inspection of your equipment’s internal structure ensures that small issues don’t develop into major problems. Simple actions like cleaning, lubricating moving parts, and replacing worn-out elements can extend the life of your machine. Understanding the role of each part makes it easier to perform these tasks efficiently and correctly.

How to Use the Components Breakdown Effectively

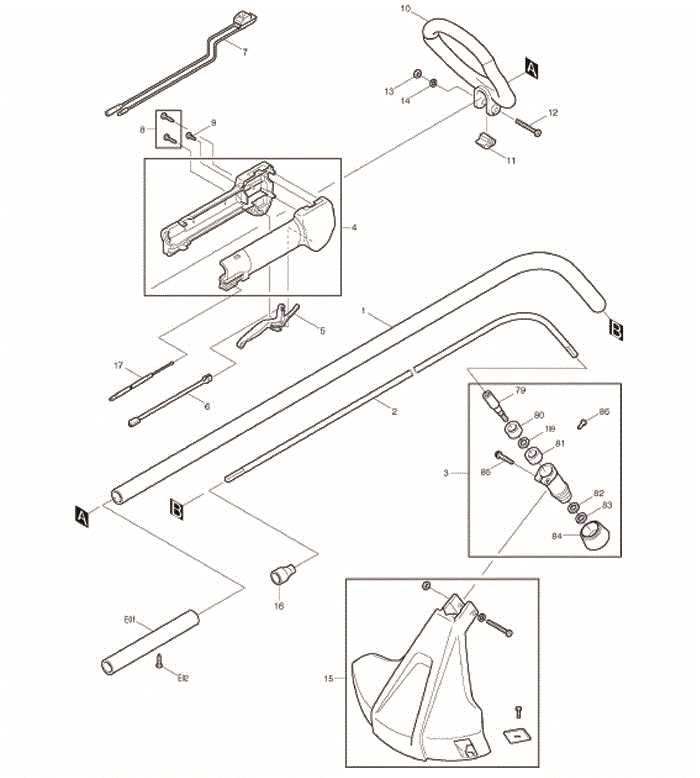

Understanding how to read and use a visual guide of your tool’s components is essential for efficient maintenance and repairs. These illustrations provide a clear view of how all elements fit together, allowing you to identify individual parts quickly. This approach can significantly streamline the repair process, helping you avoid mistakes and reduce downtime.

Step-by-Step Approach for Maximum Efficiency

To make the most of the breakdown, start by familiarizing yourself with the overall structure of your tool. Identify the key sections, such as the motor housing, drive system, and cutting components. Once you know the general layout, you can focus on specific areas where problems might arise, such as worn-out parts or damaged connections.

Finding the Right Component for Replacement

When a part needs replacement, using the guide helps pinpoint the exact item you need. The clear labels and references make it easier to compare what’s in the illustration with the actual components on your machine. Proper identification is crucial to avoid purchasing the wrong items and ensures that replacements will fit perfectly.

Common Repairs Using the Component Breakdown

Knowing how to address common issues with your lawn care tool is essential for maintaining its performance. A component breakdown serves as a valuable resource, helping you identify and replace faulty elements. By understanding the layout and functions of each piece, you can tackle a variety of repairs with confidence and precision.

Replacing the Drive Mechanism

One of the most frequent repairs involves the drive system, which can wear out over time. Using the breakdown, you can easily locate the components responsible for the drive and identify any signs of damage. Correctly replacing the damaged parts ensures the tool operates efficiently and prevents further damage to other components.

Fixing the Cutting Head

The cutting head is often subjected to heavy wear and tear, especially with frequent use. By referring to the visual guide, you can identify any worn or broken elements, such as blades or connectors. Replacing or repairing these components quickly can restore cutting performance and extend the life of your tool.