Every tool or machine requires proper understanding to ensure efficient operation and long-term durability. Familiarizing yourself with the individual elements that make up your device is essential for effective maintenance and repair.

In this section, we will explore how to identify key components, understand their roles, and recognize when parts need attention or replacement. Whether you are troubleshooting or conducting regular upkeep, this knowledge will help you maintain smooth performance.

By examining the structure of the equipment and learning about its key features, you can confidently address any issues that arise. Regular inspection and timely care can significantly extend the lifespan of your machinery.

Stihl FS 45 Overview and Components

This section provides a detailed look at the main features and elements of the cutting tool. It is designed for users seeking to understand the key parts that work together to deliver optimal performance in various tasks. The device combines powerful mechanics with reliable components, ensuring efficiency and durability over time.

Powerful Engine: At the heart of the tool lies a robust engine that drives the overall functionality. This component plays a crucial role in delivering consistent power to the cutting mechanism, making it ideal for tough outdoor tasks.

Cutting Mechanism: The cutting system is designed to tackle various vegetation types. It consists of high-quality materials that ensure precision and reliability. The system is easy to handle, providing flexibility for different working environments.

Fuel System: The fuel system includes components that ensure the engine operates smoothly and efficiently. Proper fuel management helps maintain the engine’s performance, extending its lifespan with regular upkeep.

Handle and Control: The ergonomic handle and control features are designed for comfort and ease of use. The layout of the controls provides a user-friendly experience, making it easier to operate the device for extended periods.

The overall design integrates these elements seamlessly, providing a tool that stands out for both its versatility and reliability in the field.

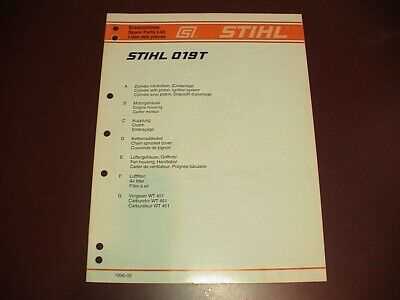

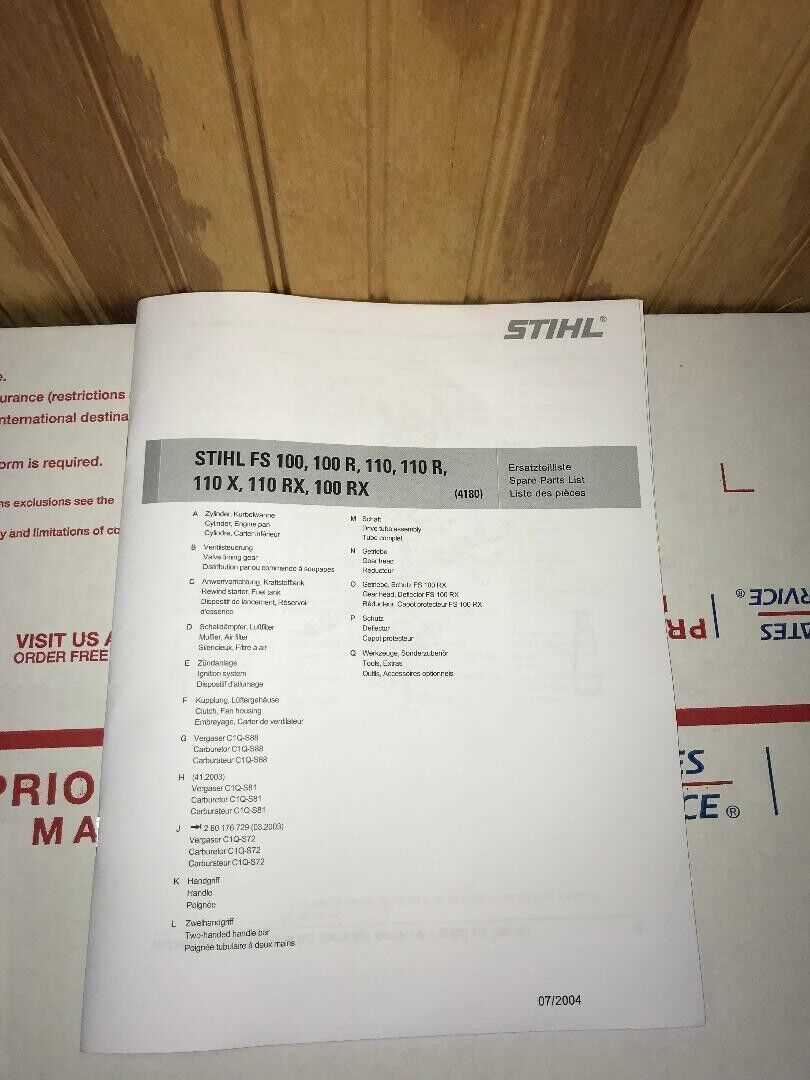

How to Read the Parts Diagram

Understanding how to interpret a visual representation of the tool’s components is essential for effective maintenance and repairs. These illustrations provide a clear view of the internal and external elements, helping users identify and locate each individual piece. Learning to read these guides can significantly ease the process of assembling, disassembling, and replacing various components.

The image typically uses a numbering system to label each item, allowing you to match these numbers with their corresponding names or descriptions. This organization aids in quickly finding the necessary part during troubleshooting or ordering replacements.

It’s important to familiarize yourself with the symbols and lines in the illustration. Lines often indicate how parts connect or interact, while certain colors or shading may highlight critical areas of the design. This clarity helps users navigate the tool’s construction and repair procedures.

By following the visual guide, you can efficiently pinpoint any worn or damaged parts that may need attention, ensuring that the tool remains in optimal working condition for longer periods.

Essential Stihl FS 45 Replacement Parts

When maintaining the functionality of any tool, there are key components that may require replacement over time due to wear or damage. These elements are critical to ensuring smooth operation and efficient performance. Regularly replacing these components helps to extend the life of the device and ensures it continues to function at its best.

The cutting mechanism is often one of the first areas where wear occurs, requiring timely replacement to maintain precision and effectiveness. Another vital component is the fuel system, as parts like filters and lines can degrade with regular use and exposure to different elements. Ensuring that these parts remain in good condition is crucial for optimal performance.

Additionally, the handle and control system, being frequently used, may also need occasional attention. These parts can become damaged or lose their effectiveness with extended usage, making it essential to replace them for continued comfort and ease of operation.

By staying proactive and replacing essential elements as needed, you ensure the tool remains in peak condition, minimizing downtime and maximizing efficiency in every task.