When maintaining a garden tool, understanding its individual components is crucial for efficient operation and long-lasting performance. Knowing how each piece works together allows you to address any issues quickly and effectively. This section provides a comprehensive overview of the essential components that make up your trimming device, helping you ensure smooth functionality and avoid unnecessary breakdowns.

By familiarizing yourself with the internal structure, you can identify common problems and perform basic repairs with confidence. Whether you’re dealing with wear and tear or conducting regular maintenance, having a clear understanding of each part’s role will save you time and effort in the long run.

Having a well-maintained tool not only improves performance but also extends the tool’s life, reducing the need for frequent replacements. This guide will show you how to efficiently troubleshoot, repair, and replace the necessary components, giving you the knowledge to keep your tool in optimal condition.

Understanding FS 55 RC Components

To maintain optimal performance of your trimming equipment, it is essential to have a clear understanding of its individual elements. Each component plays a specific role in ensuring smooth operation and reliability. Identifying and familiarizing yourself with these elements helps in addressing issues promptly and efficiently.

The core assembly consists of several crucial elements that work in unison to power the tool. These include the motor, fuel system, and control mechanisms, each contributing to the functionality of the device. Knowing how each of these pieces interacts ensures you can troubleshoot effectively and perform basic repairs as needed.

Regular inspection of the device’s individual components can prevent many common issues, ensuring long-term durability. From the engine housing to the cutting mechanism, each segment must be maintained properly to ensure reliability during operation. Understanding their purpose also helps you recognize when something is amiss, allowing for early intervention before a more serious malfunction occurs.

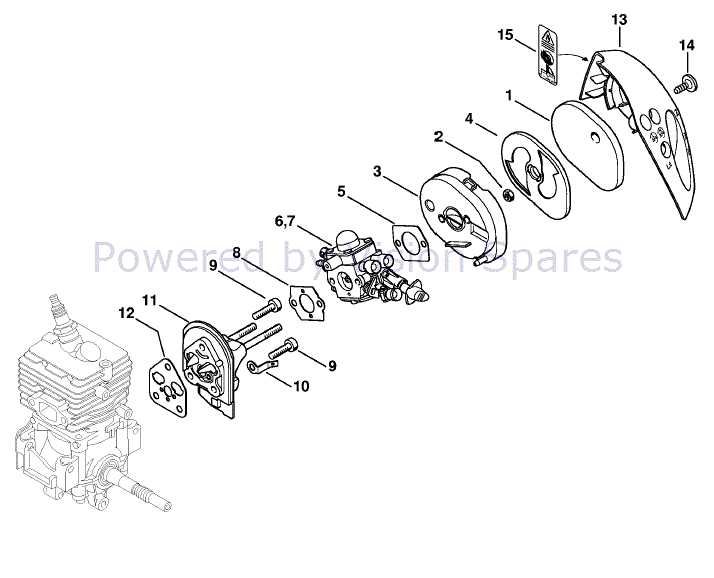

How to Use the Parts Diagram Effectively

Understanding the internal structure of your trimming tool is essential for proper maintenance and troubleshooting. Having a visual representation of the tool’s components helps you quickly identify any areas of concern. By referring to this guide, you can locate specific elements and determine how they interact with each other, making repairs or replacements simpler.

One of the most effective ways to use this visual guide is by following the numbered layout to track the arrangement and sequence of each component. This method ensures that you don’t miss any crucial steps when reassembling the device or performing maintenance. Additionally, understanding the connections between parts can help you recognize common issues that might arise during operation.

By regularly referencing this tool breakdown, you can confidently handle repairs or perform routine check-ups. Knowing exactly where each element fits and how it functions allows you to spot worn-out or damaged components more easily, ultimately helping to prolong the lifespan of your equipment.

Maintaining and Replacing FS 55 RC Components

Proper care and timely replacement of individual elements in your trimming device are key to ensuring long-lasting performance and reliability. Routine inspection helps identify any worn-out or damaged components before they affect the overall functionality. By staying proactive, you can prevent unnecessary breakdowns and avoid costly repairs.

Regular maintenance includes cleaning, lubrication, and checking for any signs of wear on crucial components such as the motor and cutting mechanism. These simple steps can greatly enhance the lifespan of your tool and ensure it continues to operate at peak efficiency. Additionally, replacing worn-out elements in a timely manner keeps your device performing optimally.

When it comes to replacing specific parts, it is essential to choose high-quality replacements that match the specifications of your tool. Following the guide to the device’s internal structure helps you easily identify which components need attention. By doing so, you can restore your equipment to full functionality without unnecessary hassle.