When it comes to maintaining your outdoor tools, understanding how all the components work together is crucial for ensuring long-lasting performance. Every piece plays a vital role in the overall efficiency of the machine, and recognizing when parts need attention can help avoid costly repairs.

By carefully studying the layout and function of each component, you can easily identify which parts require replacement or servicing. A clear visual representation can be an invaluable resource for performing maintenance tasks with precision, helping you keep your equipment in top condition.

Proper maintenance is essential for extending the life of your outdoor machinery. Regular inspection and replacement of worn-out elements will not only enhance performance but also ensure safety during use. A detailed guide can provide clarity on the most common issues and solutions, making upkeep simpler and more effective.

Understanding Stihl FS 56C Parts

Every outdoor tool consists of multiple interconnected elements, each serving a specific function to ensure smooth operation. By gaining a clear understanding of how these components fit together, you can maintain your equipment more effectively and identify any issues before they become significant problems.

It is essential to recognize the role of each individual component, from the engine to the cutting mechanism. Proper knowledge of how these elements interact allows you to perform routine maintenance with ease, preventing unnecessary breakdowns. Identifying the key components that need frequent attention or replacement helps you extend the life of your tool.

Regular upkeep of the mechanical parts, such as fuel lines, filters, and handles, is crucial for avoiding performance issues. With the right resources, you can make informed decisions on when to replace certain items. Understanding the design and function of your tool’s essential components is the first step toward keeping it running at its best.

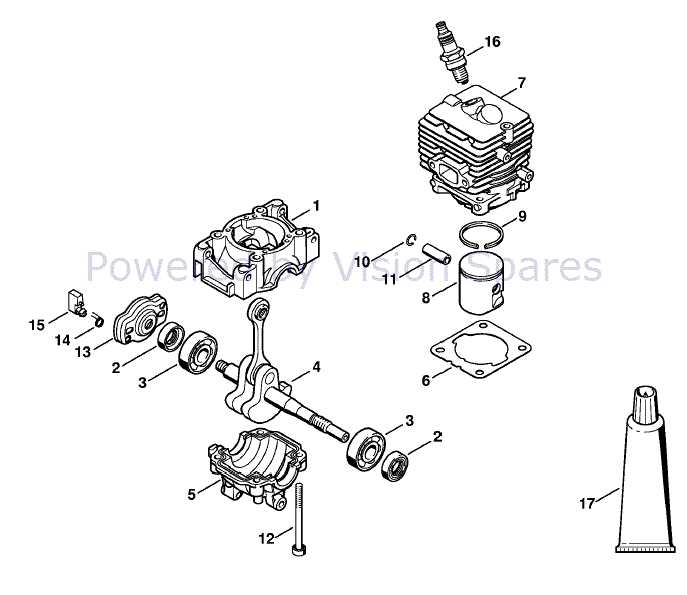

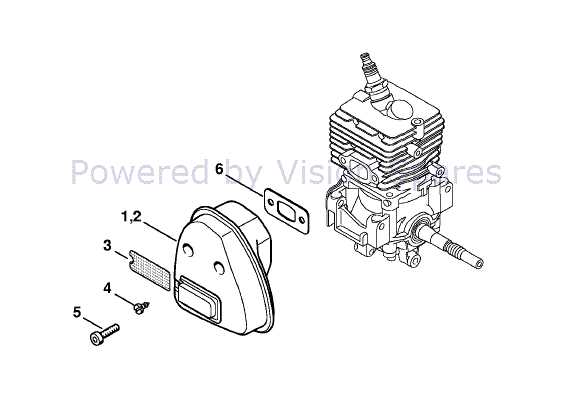

How to Use the Parts Diagram

Having a clear visual guide of your equipment’s structure can be incredibly helpful when performing maintenance or repairs. This resource allows you to pinpoint each component, making it easier to identify any damaged or worn-out parts that may need replacement.

Locating Specific Components

Once you have access to the visual guide, it is important to know where each component is located. The diagram will typically separate the parts into categories, such as the engine, fuel system, and cutting mechanism. By familiarizing yourself with the layout, you can quickly find the piece you’re looking for and understand how it fits within the overall design.

Understanding Component Functions

Alongside the layout, it’s essential to grasp the function of each component. Some elements might seem similar but serve different purposes. The diagram can help clarify these distinctions, ensuring you can troubleshoot issues accurately and replace the correct part when necessary.

Essential Replacements for Stihl FS 56C

Maintaining the longevity and efficiency of your outdoor tool requires timely replacements of its key components. Some parts wear out more quickly than others due to frequent use, and recognizing which items need replacing can save you from unexpected breakdowns and costly repairs.

Commonly Replaced Components

Several elements of your machine are more prone to wear and tear, including the fuel lines, air filters, and spark plugs. These parts play a crucial role in the overall functionality of the tool, and replacing them regularly ensures smooth operation. Fuel filters, for example, prevent dirt from entering the engine, while air filters maintain proper airflow to keep the engine running efficiently.

Signs It’s Time for a Replacement

Pay attention to how your equipment operates to determine when a part may need replacing. If you notice a decrease in performance, difficulty starting, or unusual sounds, it may be time to inspect key components. Replacing worn-out items promptly not only improves performance but also extends the lifespan of your tool, keeping it in peak condition.