Understanding the structure of outdoor power tools is essential for proper maintenance and efficient usage. The right knowledge about how different parts come together ensures smooth performance and extends the life of the equipment. Every machine has its own unique configuration of essential elements that contribute to its function and durability.

The breakdown of the main components, along with their interaction and role in the overall system, helps users make informed decisions when it comes to repairs and upgrades. Knowing how these parts fit together can also aid in troubleshooting potential issues, preventing malfunctions before they occur.

In-depth understanding of the machine’s construction can empower users to confidently carry out basic repairs and replacements when necessary. Recognizing the importance of each individual component allows for more efficient use and better care over time, enhancing the performance of the tool in any outdoor setting.

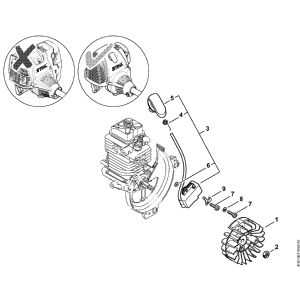

FS 91 R Components Overview

The proper functioning of a tool depends on the quality and arrangement of its individual elements. Each segment of the machine plays a crucial role in ensuring its efficient operation, from the power transmission to the cutting system. A clear understanding of these components helps users maintain their equipment in optimal condition, allowing for longer service life and improved performance.

Major Elements and Their Functions

The key components work together to deliver powerful results in various tasks. The drive system is responsible for transferring energy, while the cutting head efficiently tackles vegetation. Components such as the throttle trigger, fuel system, and safety features are designed to ensure smooth operation and user safety. Each part contributes to the overall efficiency and safety of the tool, making maintenance and proper care essential for extending its durability.

Maintenance and Replacement Considerations

Proper upkeep of these elements is vital to avoid wear and tear over time. Regular checks of the engine, fuel system, and cutting assembly ensure that the tool operates at peak efficiency. When individual components show signs of damage or degradation, timely replacement can prevent further issues and ensure consistent performance. Understanding which parts need attention helps in performing these tasks with minimal downtime.

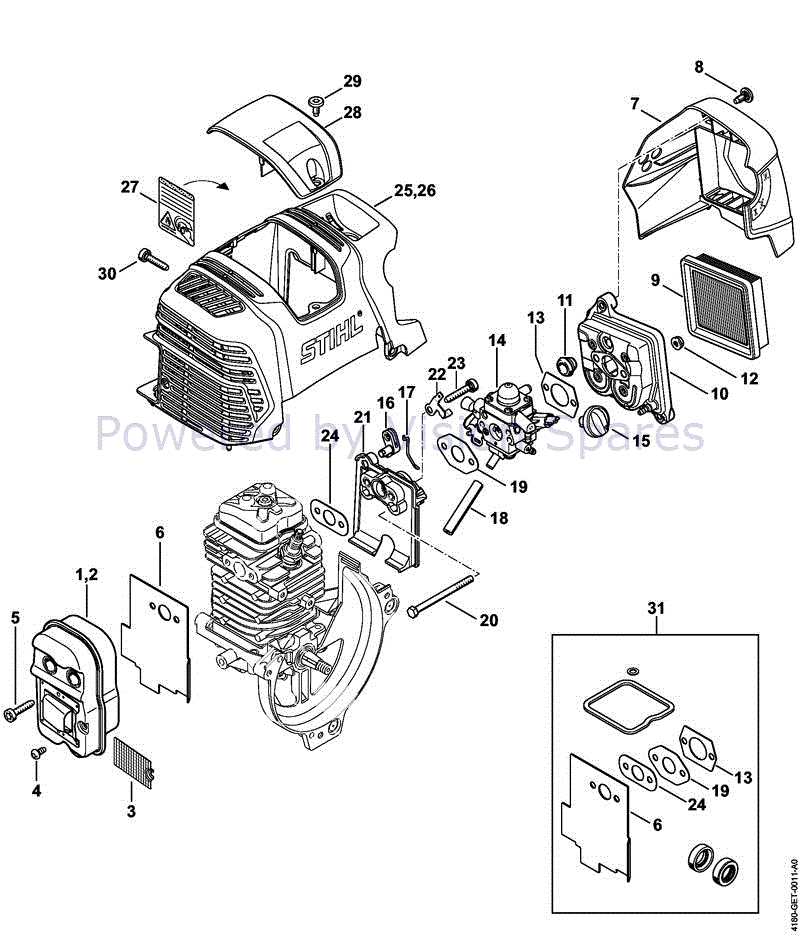

Understanding Key Components and Functions

Every outdoor power tool is made up of several critical elements, each contributing to its overall performance. These components work in tandem to ensure smooth operation, providing the necessary power and precision for various tasks. Understanding the function of each part is essential for proper maintenance, troubleshooting, and ensuring that the tool works as intended for years to come.

The core elements include the engine, fuel system, drive mechanism, and cutting head, each responsible for a specific aspect of the tool’s functionality. The engine generates power, which is transferred through the drive mechanism to the cutting head, allowing the user to carry out tasks effectively. Fuel and air systems ensure efficient combustion, while safety features are designed to protect the user during operation.

Being familiar with how these components interact with each other allows users to make informed decisions about maintenance, repairs, and upgrades. With this knowledge, keeping the equipment in optimal working condition becomes more manageable, reducing the likelihood of unexpected breakdowns.

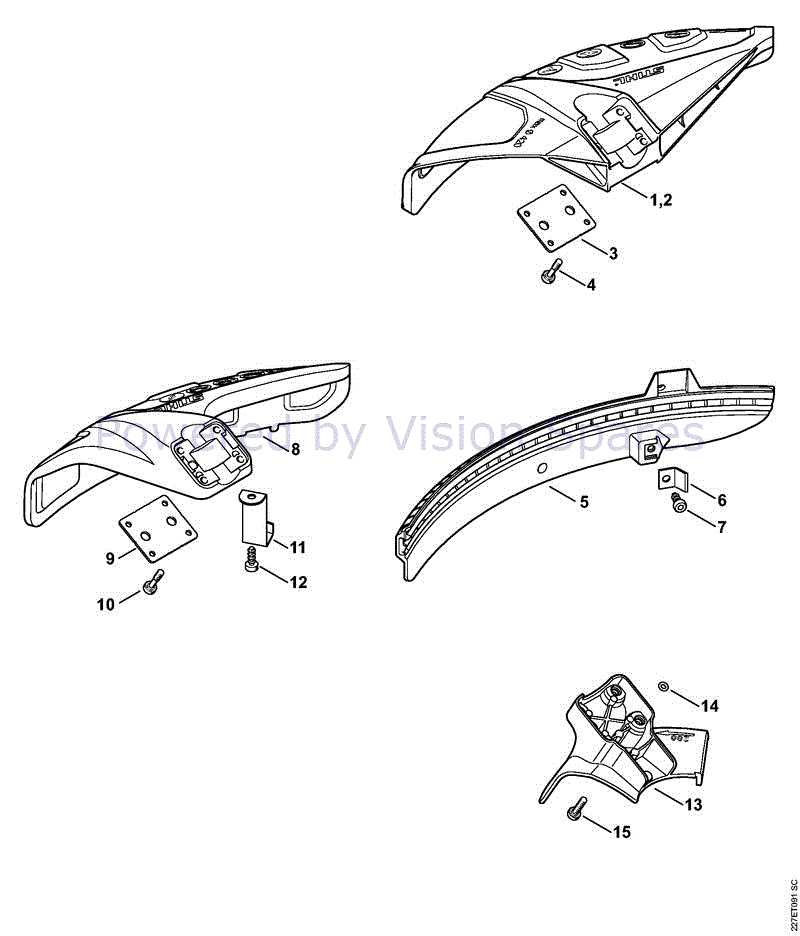

How to Identify and Replace Components

Over time, all machines experience wear and tear, and certain elements may need to be replaced to maintain optimal performance. Identifying which components are damaged or no longer functioning properly is key to keeping the tool running efficiently. Knowing how to spot these issues and properly replace the faulty parts can save both time and money, while ensuring the equipment remains in top condition.

Identifying Damaged or Worn-out Elements

Regular inspection is the first step in identifying malfunctioning components. Pay close attention to signs such as unusual vibrations, irregular sounds, or decreased performance. If any element is visibly cracked, frayed, or worn, it may be time for a replacement. Engine performance and fuel efficiency can also be good indicators of internal component issues.

Replacing the Faulty Component

Once a damaged part is identified, the next step is replacing it. Ensure you have the correct replacement for the specific part you are addressing. Refer to the manufacturer’s guidelines for proper installation and follow the recommended steps carefully. Taking the time to install the new part correctly will restore the functionality of the tool and ensure its safe operation. If you’re unsure, don’t hesitate to seek professional assistance for more complex replacements.