Maintaining a lawn trimmer requires a clear understanding of its structure and the various components that work together to ensure optimal performance. A detailed visual reference can help in identifying each part’s function and its role in the overall machine operation.

In this guide, we explore the different elements of your equipment, making it easier to troubleshoot, replace, or upgrade individual sections when necessary. By familiarizing yourself with the key components, you can ensure that your trimmer remains in excellent condition, minimizing downtime and enhancing longevity.

Stihl FS 94 R Parts Overview

Understanding the essential components of your lawn trimmer is crucial for proper maintenance and repair. Each individual part plays a key role in ensuring the efficient functioning of the machine. By knowing the layout and function of these elements, you can identify potential issues and address them swiftly, enhancing the overall lifespan of your equipment.

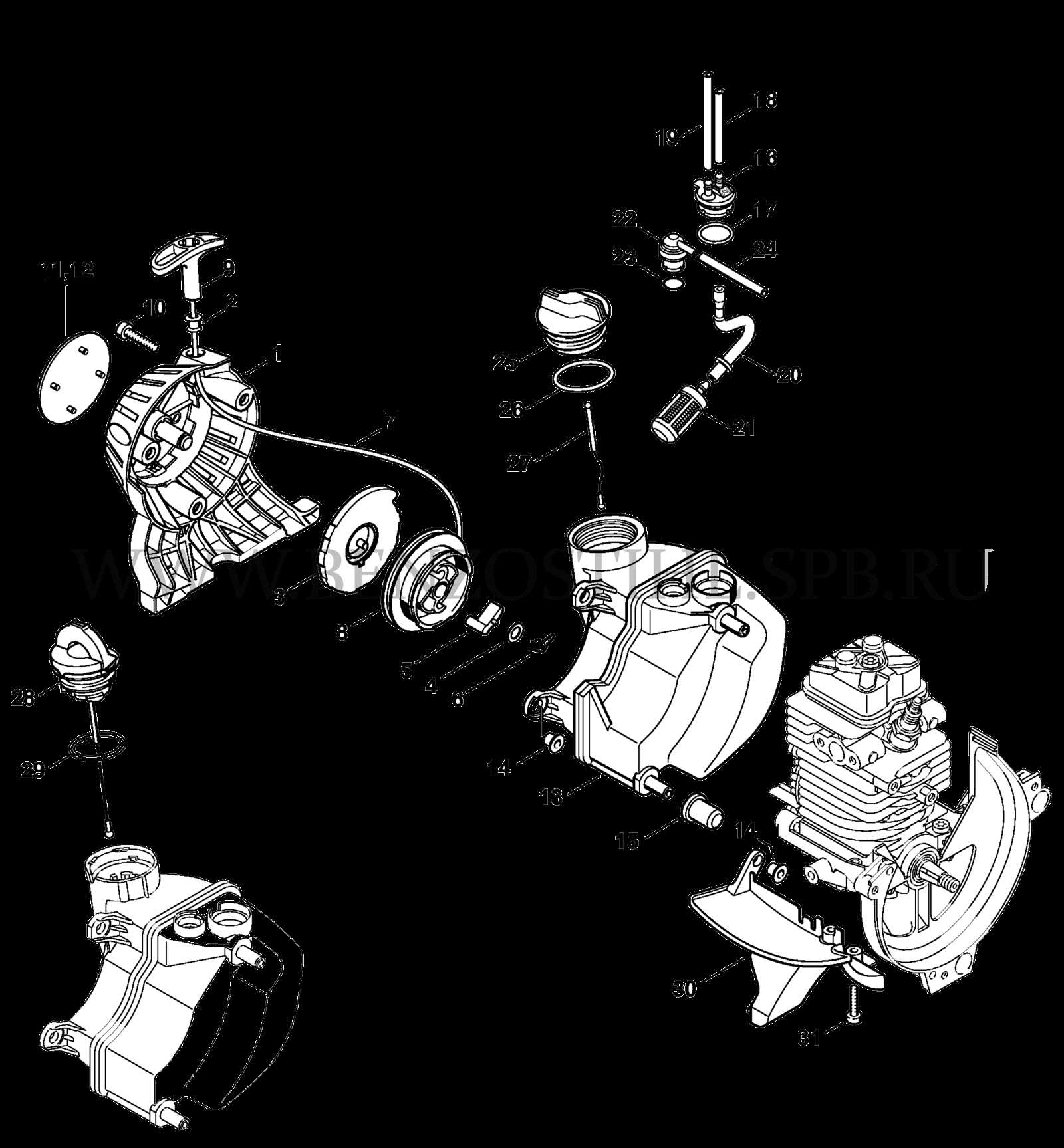

Main Assembly Components

The main assembly includes critical items such as the engine housing, drive shaft, and handlebar system. These parts work together to provide power transmission and control, ensuring a smooth operation. Recognizing how each part contributes to the overall performance can help you perform necessary adjustments or replacements effectively.

Accessory and Support Elements

In addition to the main components, various supporting elements like the fuel tank, air filter, and ignition system also play vital roles in the operation of the trimmer. Keeping these parts in good condition is essential to maintain optimal performance and avoid malfunctions that could interrupt your work.

Understanding Key Components and Functions

Every piece of equipment is made up of several interconnected systems, each playing a vital role in ensuring smooth performance. Understanding these systems and their functions helps in troubleshooting, maintaining, and replacing elements when needed. This knowledge allows you to maximize efficiency and reduce the likelihood of breakdowns.

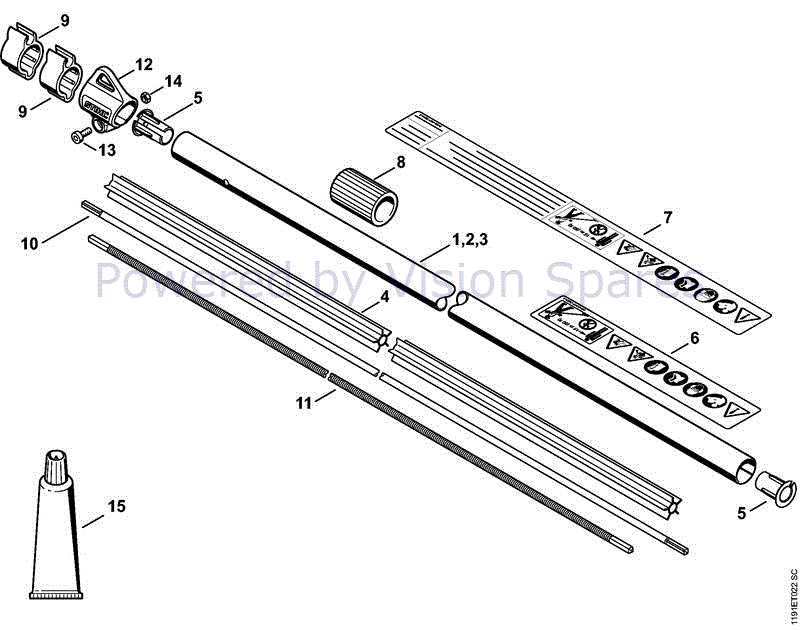

Power Transmission and Control

At the core of the machine lies the power transmission system, responsible for converting energy from the engine to the rotating head. Components like the drive shaft and gearbox are integral to ensuring that the power is properly transferred, allowing for effective cutting and trimming. Maintaining these parts is essential for consistent operation.

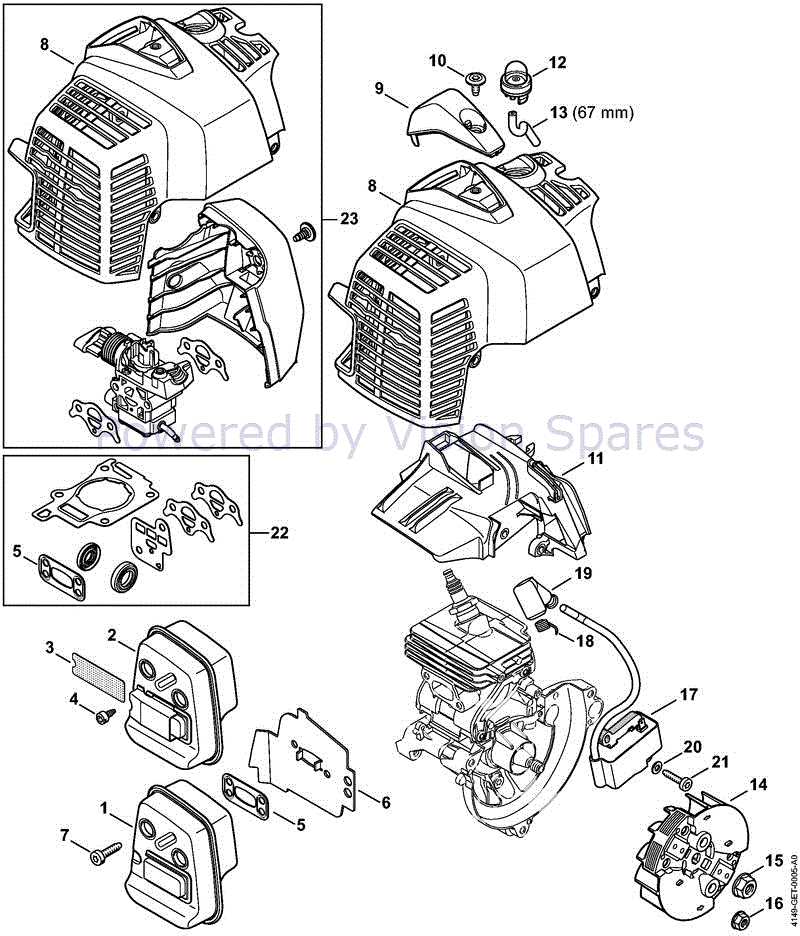

Fuel and Ignition Systems

The fuel and ignition systems are key to the engine’s operation. The fuel tank ensures that the engine receives the proper fuel mixture, while the ignition system is responsible for starting the engine. Regular maintenance of these systems ensures reliable startup and efficient operation, reducing the risk of engine failure during use.

How to Use the Parts Diagram Effectively

When performing maintenance or repairs, having a clear visual reference can make the process much easier. A well-organized visual guide allows you to identify specific components quickly, ensuring you can focus on what needs attention. Understanding how to read and interpret these references is key to maintaining efficiency during repairs.

Identify and Locate Components

Start by familiarizing yourself with the layout and structure of the reference. The components are often labeled with numbers or names, allowing you to quickly locate the specific part you’re dealing with. By cross-referencing the visual guide with your equipment, you can ensure you’re working with the correct elements during maintenance.

Follow Assembly and Disassembly Instructions

A comprehensive visual guide will also provide step-by-step instructions for disassembling and reassembling the machine. Following these instructions ensures that you don’t overlook important steps, and it helps avoid damage when reassembling. This organized approach guarantees that all parts are properly aligned for optimal performance.