Understanding the internal structure of your tool is crucial for its proper maintenance and long-term performance. This guide will provide you with a clear overview of the different components and their functions, helping you identify any worn-out or damaged parts that need attention. Whether you’re a professional or a hobbyist, knowing how to maintain your equipment efficiently can save both time and money.

By familiarizing yourself with the layout and connections of the key elements, you can easily spot any issues that may arise during use. Accurate knowledge of the individual pieces not only helps with repairs but also ensures the safety and reliability of your device over time. A thorough understanding leads to better decision-making when it comes to replacements and upgrades.

In the following sections, we will guide you through the essential details to help you perform routine inspections and necessary repairs. Proper upkeep will keep your equipment operating at its peak for years to come, preventing unnecessary breakdowns and maximizing its efficiency.

Understanding the Key Components

Each tool is made up of various elements that work together to ensure smooth operation. Recognizing how these pieces interact with one another can significantly enhance your ability to maintain the equipment effectively. Familiarizing yourself with the essential components not only aids in identifying problems but also improves the overall performance of the device over time.

Main Functional Elements

The main components serve as the foundation for how the device operates. These include both mechanical and electronic parts, each designed to handle specific tasks. For example, the motor is responsible for generating the necessary power, while the drive mechanism transfers that power to the cutting attachment. By understanding the role of each part, you can troubleshoot more efficiently and determine when replacements are necessary.

Interconnected Systems

Several components are interconnected, and their performance is directly linked. A malfunction in one area can often affect others, which is why it’s crucial to have a holistic understanding of how each element contributes to the device’s function. Regular checks and maintenance can prevent a small issue from escalating into a bigger problem, ensuring consistent performance.

Proactive maintenance is key to avoiding wear and tear that can compromise efficiency. Understanding these interconnected systems allows for early detection of faults, making repairs and replacements simpler and more cost-effective in the long run.

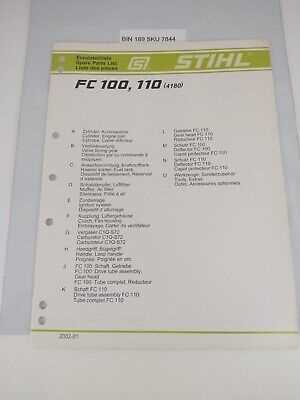

How to Read the Components Layout

Understanding the layout of your equipment’s components is essential for effective maintenance and repair. By interpreting the visual representation correctly, you can easily identify the various parts and their locations within the system. This knowledge is crucial when troubleshooting or replacing elements of the machine, ensuring that you can address issues with precision and confidence.

Understanding Visual Indicators

The layout typically features a series of labeled components, each representing a different part of the device. The labels are often accompanied by numbers or codes that correspond to specific descriptions. These indicators make it easier to match the visual representation with the actual components. Take note of how the elements are connected, as this can help you understand their function and identify potential points of failure.

Step-by-Step Guide to Interpreting the Layout

Start by identifying the main sections of the device, such as the motor, housing, and drive system. Focus on the larger components first, then move to the smaller, more detailed parts. The connections between the components will often be highlighted, allowing you to trace the flow of energy or motion. This step-by-step approach helps break down complex systems into manageable parts, making it easier to spot worn or damaged sections.

Clear identification of each component ensures that you make the right repairs and replacements without confusion. Understanding the layout will also save time by allowing you to locate the exact part that requires attention.

Essential Tips for Replacing Components

Replacing worn or damaged elements in your equipment is a crucial aspect of maintenance. Knowing the right approach ensures that the replacement process is efficient and that the tool continues to operate at peak performance. Here are some essential tips to help you navigate through the process of swapping out faulty pieces with ease.

Prepare and Gather Necessary Tools

Before starting the replacement, make sure you have all the required tools at hand. This includes basic hand tools such as screwdrivers and wrenches, as well as any special tools recommended by the manufacturer. Having everything ready will save time and prevent interruptions during the procedure. Additionally, ensure that the replacement components are compatible with your device to avoid unnecessary complications.

Follow Manufacturer Guidelines

Always refer to the user manual or manufacturer’s instructions when replacing any component. These guidelines provide specific steps to ensure correct installation and prevent potential issues. Pay close attention to the recommended torque settings, part orientations, and safety measures. Following these instructions precisely will minimize the risk of errors and extend the lifespan of your equipment.

Proper installation is vital for the tool’s functionality. Ensuring that each element is securely fitted and correctly aligned will prevent unnecessary wear and damage, maintaining optimal performance over time.