When it comes to maintaining your outdoor equipment, having a clear understanding of its internal structure is essential. Knowing how different elements interact with each other ensures that repairs are done correctly and that the machine continues to perform at its best. Proper maintenance can extend the lifespan of the equipment, preventing costly breakdowns and enhancing its efficiency.

In this guide, we will explore the key components of your tool and how they work together. Whether you’re replacing a faulty piece or performing routine upkeep, familiarizing yourself with these parts will help you identify potential issues and make informed decisions. A detailed reference to these elements can significantly improve your repair process.

By examining the layout and arrangement of the tool’s internal pieces, you’ll gain a better perspective on its design and functionality. This will not only aid in repairs but also provide a deeper understanding of how each component contributes to the tool’s overall performance.

Understanding the Tool’s Internal Layout

To properly maintain and repair your outdoor equipment, it’s crucial to have a clear understanding of its internal structure. A well-organized assembly ensures that each component functions optimally, and recognizing how the various parts are arranged helps in identifying problems quickly. This knowledge not only facilitates repairs but also allows for efficient maintenance, ensuring the longevity of the machine.

Key Components and Their Functions

The machine is made up of several key components, each playing a specific role in its overall operation. The engine, for instance, is the heart of the tool, while other smaller elements, such as the fuel system and ignition system, work together to ensure smooth performance. Familiarizing yourself with these major components and their interactions is essential for troubleshooting and fixing any issues that arise.

Identifying Wear and Tear

Understanding the layout also helps in detecting parts that are more likely to wear out over time. Components like the air filter, spark plug, and drive shaft are subject to constant use and may degrade faster than others. Knowing where these parts are located and how they connect to the rest of the machine can help you identify when they need attention or replacement.

How to Use the Tool’s Component Layout

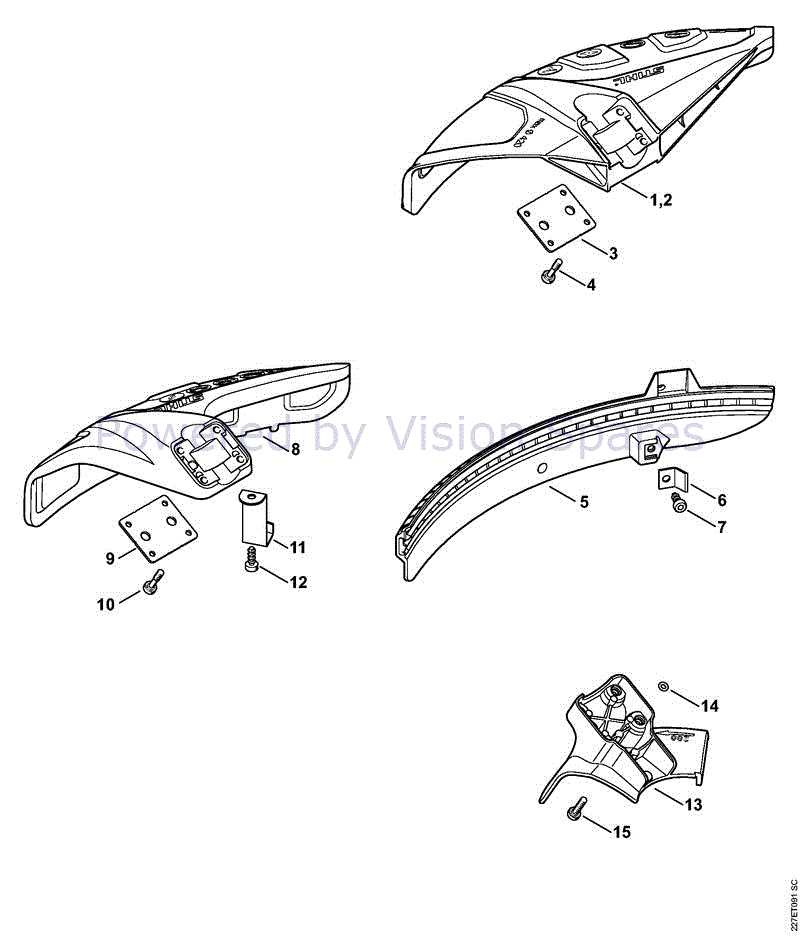

Using an internal layout reference can greatly simplify the process of maintaining and repairing your equipment. By providing a clear visual representation of the tool’s structure, it allows you to identify each individual element, understand its placement, and see how it interacts with other components. This guide will help you effectively use such a reference to streamline your repair and maintenance tasks.

Start by locating the specific section relevant to the part you want to address. The layout usually groups components based on their function, such as the engine assembly, fuel system, or electrical components. Carefully compare the visual representation with your tool to identify any missing, worn, or damaged pieces. This visual aid will guide you through the repair process and help ensure that every component is correctly installed or replaced.

Once you have identified the necessary parts, cross-reference the layout with the tool’s user manual or service guide. This will ensure compatibility and help confirm the correct orientation or installation method. When dealing with complex repairs, having a detailed component map ensures that each step is completed accurately, minimizing errors and downtime.

Common Issues with Outdoor Equipment Components

When working with outdoor tools, certain components are more prone to wear and tear due to constant use and exposure to harsh conditions. Over time, parts may degrade, causing the equipment to function improperly or even break down. Recognizing the common issues with these components can help prevent unexpected failures and improve the overall performance of your tool.

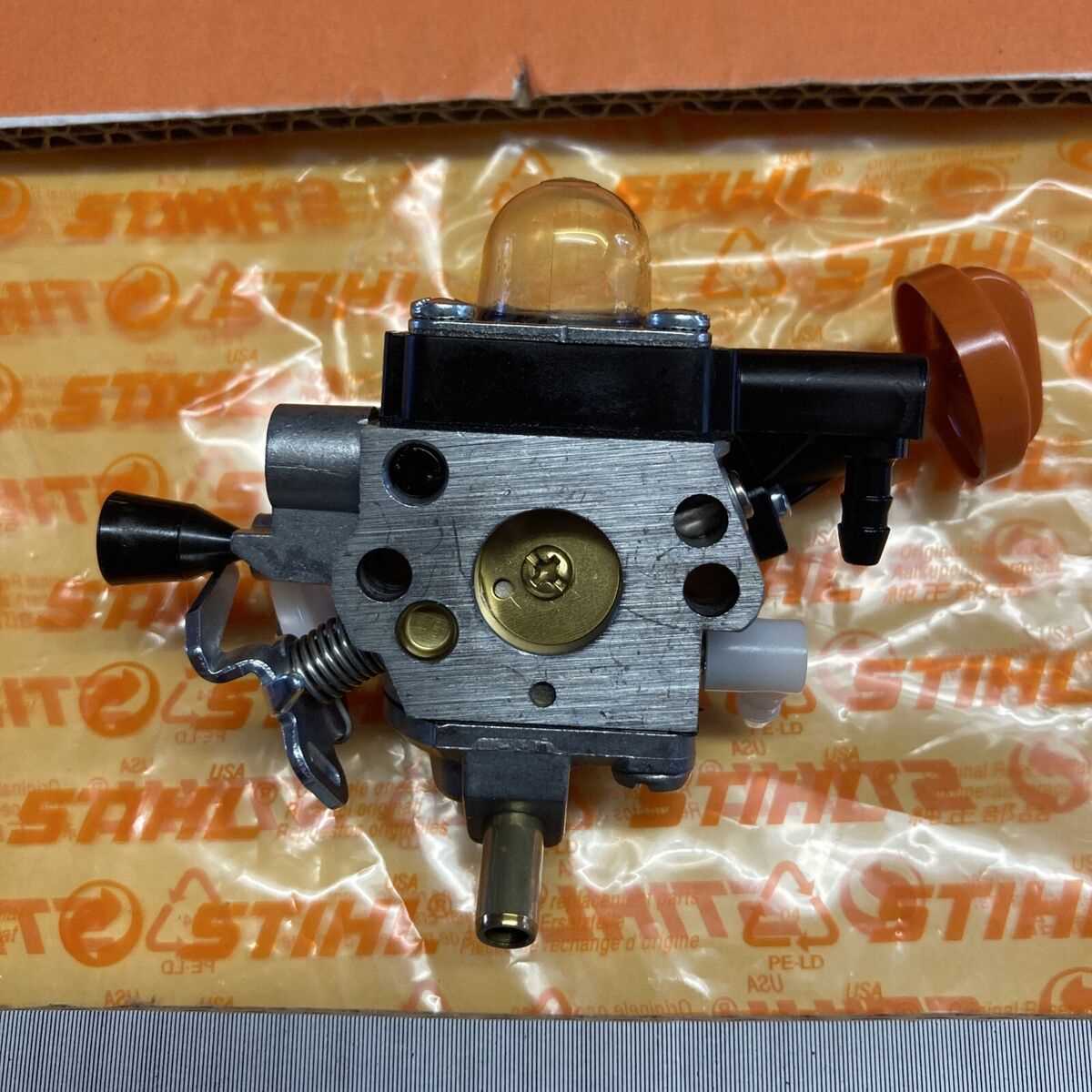

Fuel System Problems

A common issue is the clogging or degradation of the fuel system. Filters and fuel lines can become blocked with debris or old fuel, preventing the engine from receiving the necessary amount of fuel. Over time, rubber hoses can crack or harden, leading to fuel leaks. Regularly inspecting the fuel system and replacing any worn parts can help maintain smooth operation.

Ignition System Failures

The ignition system is another area where problems often occur. Spark plugs can become dirty or worn out, leading to poor starting or misfires. A faulty ignition coil or wire can also prevent the engine from starting. These issues are generally easy to diagnose and can often be resolved by cleaning or replacing the affected parts. Maintaining the ignition system ensures that your tool starts reliably and operates efficiently.