For efficient lawn care, understanding the inner workings of your equipment is crucial. Knowing how each element functions can significantly enhance the maintenance and longevity of your tool. This guide will provide insight into the key elements that make up your trimmer, helping you manage repairs and upgrades with confidence.

Recognizing and identifying the different parts of a trimmer will allow you to troubleshoot issues effectively and avoid unnecessary replacements. Whether you are a beginner or experienced user, this overview will assist you in comprehending how all the components fit together for optimal performance.

Proper maintenance can extend the life of your machine, reduce downtime, and ensure you get the most out of every use. By understanding the layout and function of each piece, you can handle basic repairs yourself and avoid costly service calls.

Understanding Trimmer Component Layout

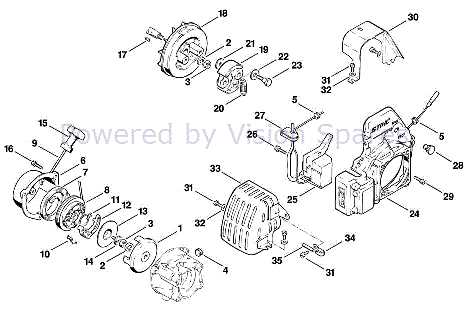

Gaining a clear understanding of the internal layout of your trimmer is essential for proper maintenance and repair. Each piece within the tool serves a specific function, and knowing where they fit and how they work together allows for better performance and easier troubleshooting.

By familiarizing yourself with the different sections of the machine, you can identify potential issues early on and address them before they cause significant damage. This knowledge is especially useful when replacing damaged or worn-out components, ensuring you select the correct replacements.

A detailed view of the machine’s structure provides a visual representation of how each component interconnects. This can help you visualize the step-by-step process of disassembling or reassembling your tool for regular upkeep or repairs.

How to Identify Trimmer Components

Recognizing the individual parts of your trimmer is crucial for effective maintenance and repair. Each section plays an important role in the overall functionality of the tool, and being able to distinguish between them ensures you can address any issues that arise.

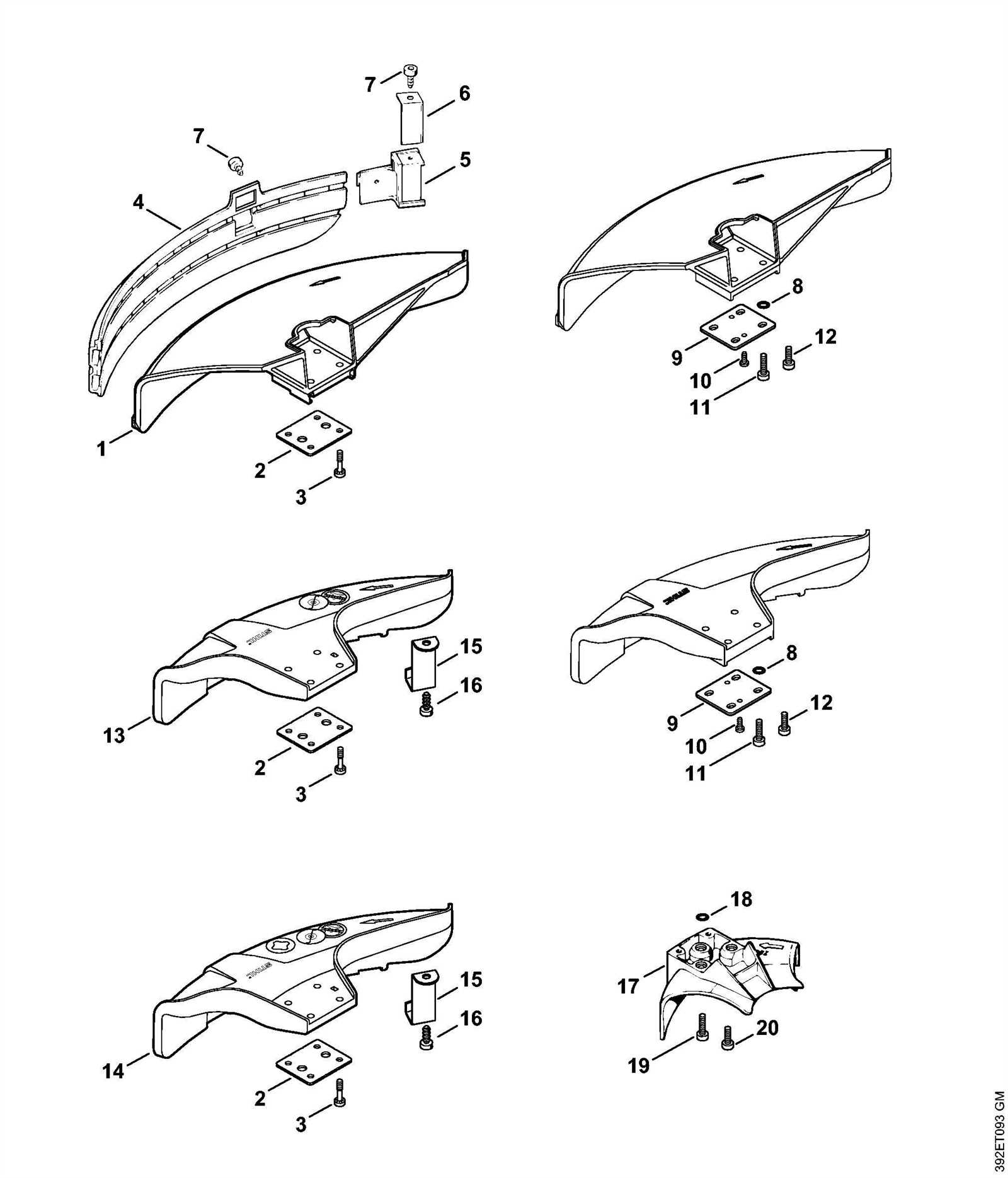

Start by familiarizing yourself with the key elements that make up the trimmer, such as the engine, shaft, cutting head, and handle assembly. Once you can visually identify these main sections, you can proceed to smaller components like springs, washers, and fasteners that support the larger parts.

Clear identification of components helps prevent mistakes during repairs, reduces the risk of using incompatible parts, and allows for more efficient troubleshooting when something goes wrong. Knowing where each piece fits into the overall structure also aids in proper reassembly after maintenance tasks.

Common Repairs with Trimmer Components

Regular use of your trimmer may lead to wear and tear, making it essential to perform repairs as needed. Addressing common issues with individual components can restore the tool’s efficiency and prevent further damage.

One of the most frequent repairs involves the cutting head, which can become clogged or damaged over time. Replacing the line or checking for any obstructions is often necessary to keep the tool functioning properly. Additionally, inspecting the engine and fuel system for leaks or blockages ensures that the machine runs smoothly.

Replacing worn-out or broken components like the trigger mechanism or clutch springs is another common repair. Recognizing when a part needs replacing will help prevent malfunctioning, making your trimmer reliable and extending its service life.