Maintaining and repairing your lawn care equipment becomes much easier when you have a clear understanding of its internal structure. Knowing how different parts fit together and function is key to ensuring longevity and optimal performance. Whether you’re a novice or experienced user, having a detailed reference can save you time and effort when troubleshooting or upgrading your machine.

Accurate identification of components is essential for resolving any issues that may arise. With the right reference material, you’ll be able to pinpoint malfunctioning or worn-out parts quickly, making the repair process more efficient. This guide will help you navigate through the various sections of your machine, providing a clearer picture of its intricate setup.

By breaking down each critical piece and understanding its role, you’ll be empowered to tackle maintenance tasks with confidence. Equipped with this knowledge, you’ll be prepared to address potential problems and keep your equipment running smoothly for years to come.

Understanding Trimmer Components Layout

For efficient maintenance and repair of your equipment, it’s crucial to familiarize yourself with the layout of its key components. Understanding how each part connects and functions allows for faster troubleshooting and ensures that any replacement or repair is done correctly. A detailed overview of the internal structure helps identify critical areas that may need attention over time.

Key Elements of the Equipment’s Structure

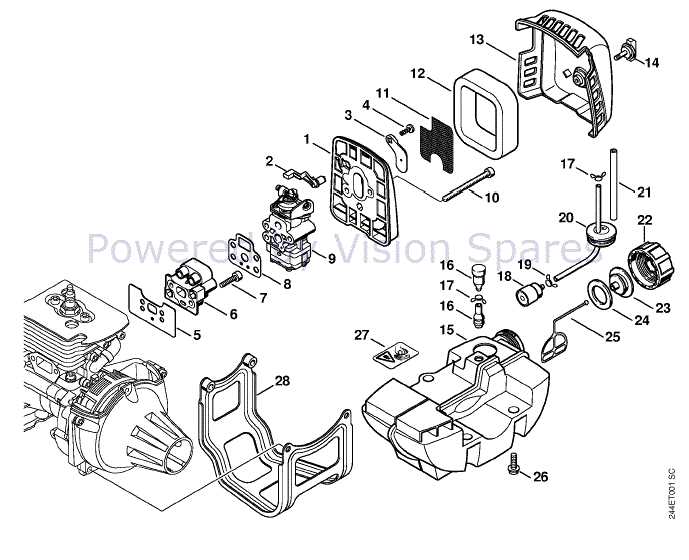

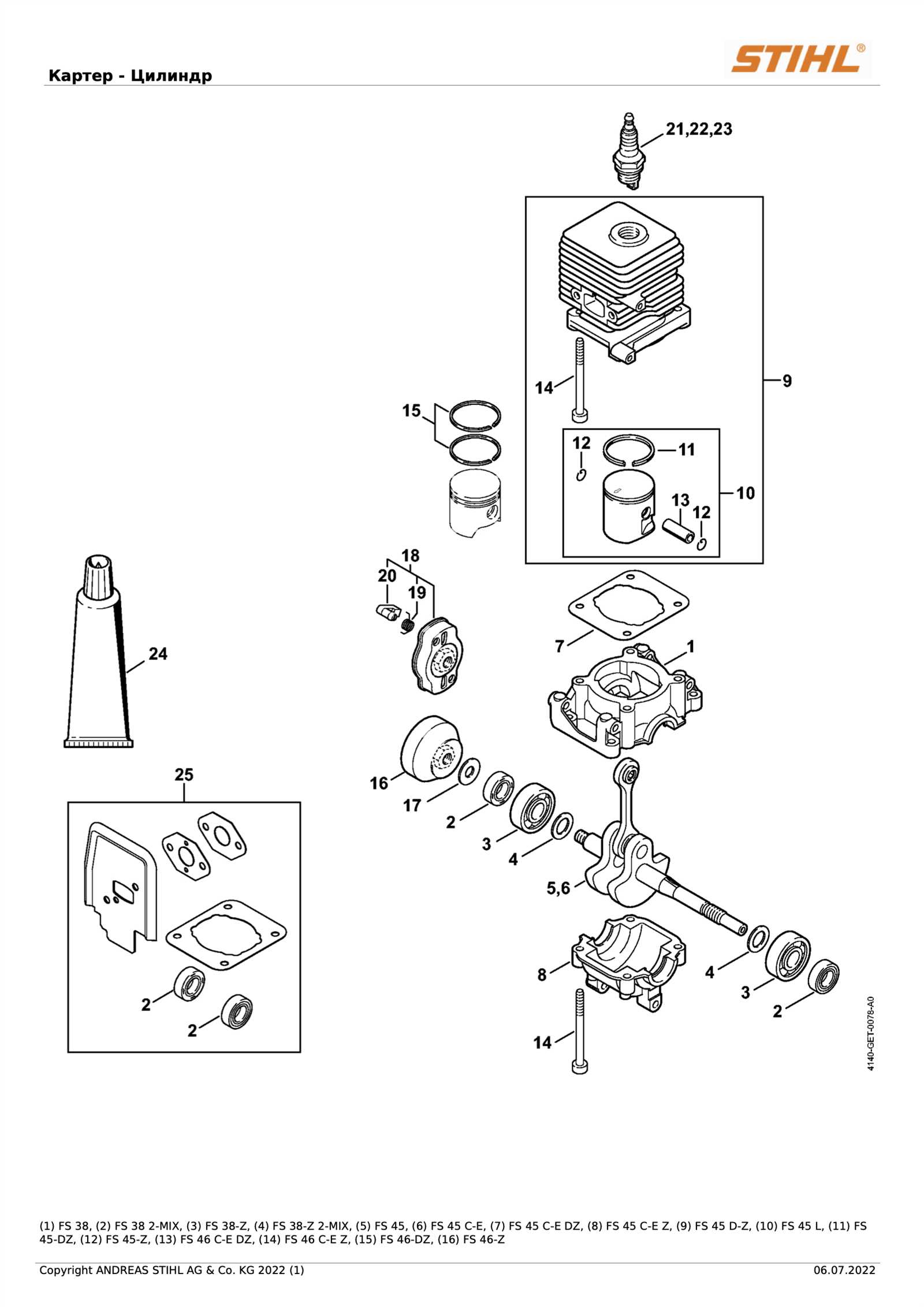

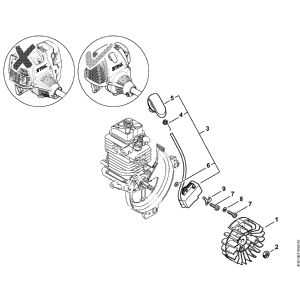

Each section of the machine serves a specific function, contributing to its overall performance. Engine components, fuel systems, and cutting tools are among the most essential, requiring regular inspection and occasional replacement. Being able to identify each piece in the system ensures you can address wear and tear effectively and maintain the equipment’s efficiency.

How to Navigate the Internal Layout

When faced with a malfunction, understanding the positioning of various elements is crucial. Clear identification of each component, from the drive shaft to the handles, will help you quickly locate issues and reduce downtime. This knowledge gives you the tools to carry out maintenance tasks with greater accuracy and confidence.

Identifying Key Components in the Diagram

Recognizing the vital components of your equipment is the first step toward effective maintenance and repairs. A clear understanding of each part’s function and location helps ensure that you can address any issues with precision. This knowledge allows you to quickly assess what needs attention, whether it’s a damaged part or a piece that’s simply worn out over time.

When examining the layout, focus on the most critical elements that influence the machine’s performance. Key components such as the engine, fuel system, and cutting mechanism should be easily identifiable, as they directly affect how the equipment operates. Understanding their placement will also aid in efficient assembly and disassembly during maintenance tasks.

How to Use the Equipment Layout

Effectively utilizing a reference for your machine’s components requires understanding how each part is represented and its role in the overall structure. With a clear overview of the internal layout, you can easily identify and troubleshoot issues, as well as streamline the repair or replacement process. Knowing where each part is located allows for quicker and more accurate maintenance, saving both time and effort.

Step-by-Step Assembly and Disassembly

Using the reference guide for assembly or disassembly involves starting from the most foundational components and working your way through the system. Focus on understanding the flow of operation, from the engine to the cutting mechanism, ensuring each part is securely positioned. This approach ensures you don’t miss any critical steps during setup or repair.

Locating Faulty Components for Quick Fixes

Once you’re familiar with the layout, identifying a malfunction becomes much easier. By knowing the position of the key components, you can efficiently locate damaged or malfunctioning elements. This method minimizes downtime and ensures that you can get your equipment back in action as quickly as possible.

Step-by-Step Guide for Assembly and Repair

When performing assembly or repairs on your machine, following a structured process ensures that all components are correctly installed and functional. This guide outlines each essential step to help you work methodically, reducing the chances of error and enhancing the overall efficiency of the repair. By systematically addressing each section, you can ensure that the equipment is restored to optimal performance.

Start by preparing your workspace to ensure that you have the necessary tools and a clean area to work in. Having everything in place before you begin will minimize distractions and ensure a smoother process. Next, identify the primary components involved in the repair or assembly, such as the engine, fuel system, and cutting parts, and follow the correct sequence for reassembling each piece.

Take your time during each step, ensuring that each part is securely connected before moving on. Pay close attention to any potential signs of wear or damage while assembling, as this could affect the machine’s performance. Completing each step carefully will help you achieve a seamless reassembly or repair, prolonging the life of your equipment.

Common Issues and Parts Replacement

Over time, certain components of your equipment may wear out or malfunction, leading to performance issues. Recognizing these common problems early allows for quicker solutions and ensures that your machine remains functional. Replacing faulty parts with the correct replacements is essential to maintaining the efficiency of the equipment. Here, we’ll explore some frequent issues and the necessary steps for replacing the affected components.

- Engine Performance Problems: Reduced power or irregular operation can be caused by a malfunctioning engine component. Inspect fuel lines, spark plugs, and filters for damage or clogging.

- Cutting Mechanism Failures: If the cutting tool is dull, misaligned, or damaged, it can significantly affect performance. Check for wear and replace blades or trimmer heads as needed.

- Fuel System Issues: Difficulty starting or erratic behavior may stem from clogged fuel lines or a dirty carburetor. Cleaning or replacing these parts can restore normal function.

Proper part replacement not only resolves these issues but also improves the overall performance of your equipment. Ensure that the replacements are of high quality and designed for compatibility with your machine for best results.