Knowing the internal components of your tool is essential for effective maintenance and repair. This guide will provide you with a clear understanding of how different parts are organized and interact with each other. Having this knowledge allows you to identify potential issues and address them efficiently.

Accurate identification of each component is crucial for successful servicing. By referencing a detailed breakdown, you can ensure that you have all the necessary parts and avoid errors during assembly or disassembly. It also helps in understanding the relationship between each element and how they contribute to the overall functioning.

In addition to troubleshooting, knowing the individual components can help you optimize performance and extend the lifespan of your tool. Understanding where each piece fits and functions ensures that repairs are done correctly, saving you time and resources in the long run.

Understanding the Components of Your Equipment

Familiarizing yourself with the individual elements of your tool enhances its efficiency and longevity. Every machine is made up of various parts that work together to perform specific tasks. Gaining insight into these components not only aids in smoother operations but also simplifies maintenance and repair processes.

Key Elements for Effective Operation

Each tool is built with core components designed to handle particular functions. From the engine to the cutting mechanism, understanding how each part interacts with others allows you to troubleshoot and resolve issues with ease. Recognizing wear and tear on individual components can help you avoid costly repairs and optimize performance over time.

Maintenance and Troubleshooting

Knowing where each piece fits within the assembly is vital for effective upkeep. Regular maintenance ensures that each element continues to work efficiently. Troubleshooting becomes easier when you’re familiar with how the different parts contribute to the tool’s overall functionality, leading to quicker resolutions and fewer disruptions during use.

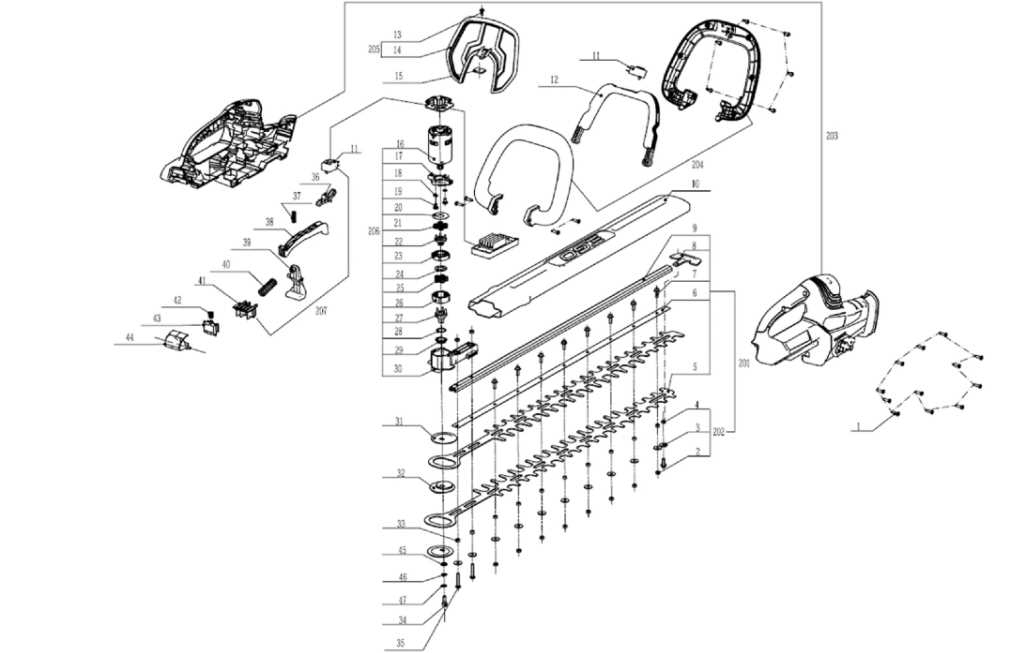

How to Read a Breakdown for Maintenance

Understanding a detailed breakdown of your tool is essential for proper upkeep. These visual representations serve as guides, illustrating how each element fits together and where potential issues might arise. Interpreting them correctly allows you to identify the right components for repairs or replacements, streamlining the maintenance process.

Identifying Key Components

Each symbol or part on the breakdown corresponds to a specific component of the tool. Pay attention to the labels and numbers that indicate individual pieces. By following the diagram closely, you can pinpoint where each part belongs and assess if it’s functioning properly or needs replacement.

Using the Breakdown for Efficient Repair

A breakdown is not just for identifying components; it’s also a tool for simplifying repairs. When something malfunctions, refer to the breakdown to locate the affected part. This visual reference helps you understand the assembly order, making disassembly and reassembly easier, and ensuring that everything fits back into place accurately.

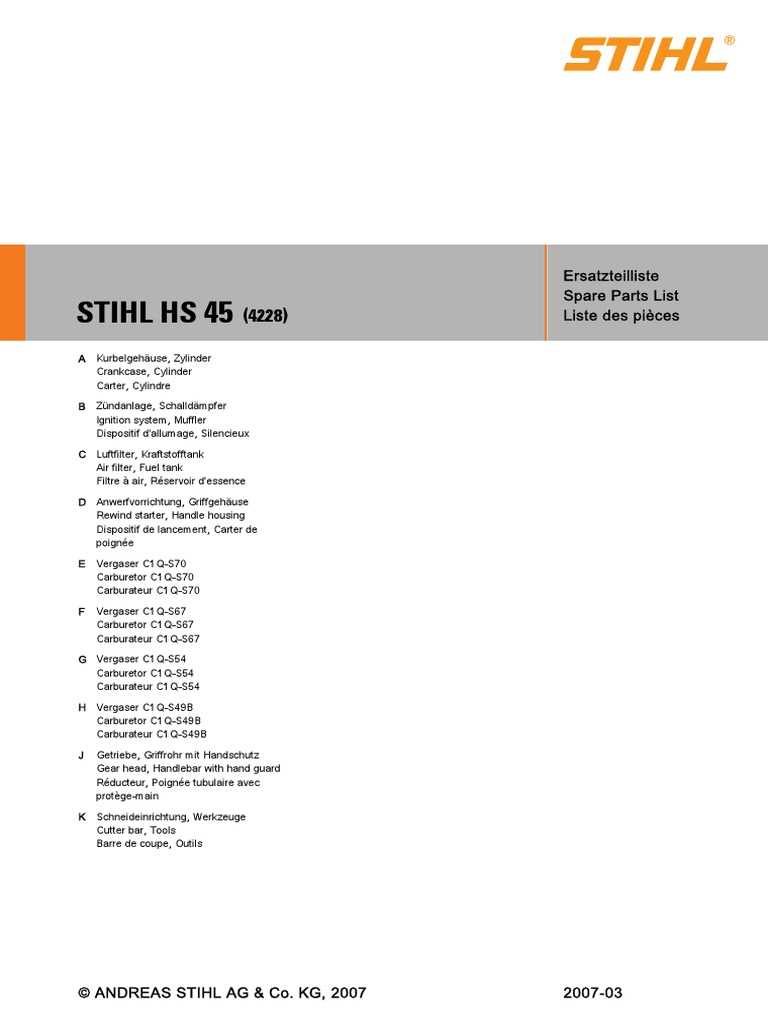

Common Issues and Spare Components for Your Tool

Every tool experiences wear and tear over time, leading to various issues that can affect performance. Recognizing these common problems early on and knowing the replacement components can help maintain the tool’s efficiency. This section explores some typical concerns and how understanding spare parts can aid in quick fixes.

Frequent Problems and How to Address Them

Clogging or difficulty starting is a common issue, often caused by a buildup of debris or worn-out components. Cleaning or replacing specific parts can resolve this problem. Similarly, engine stalling may point to a malfunction in the fuel system or ignition parts, which can be easily identified and replaced when needed.

Essential Spare Components for Repair

Knowing which spare parts are commonly required for maintenance helps in reducing downtime. Key components such as spark plugs, filters, and air intakes should be kept on hand for regular servicing. Understanding their function ensures that you can make timely replacements and keep your tool in optimal condition.