Maintaining outdoor tools and machinery requires an understanding of their intricate parts and how they function together. Whether you are a professional or an enthusiast, knowing how each element fits and operates can ensure longevity and efficient performance. This section focuses on helping you navigate the essential elements of your device and provides a clear layout for effective upkeep.

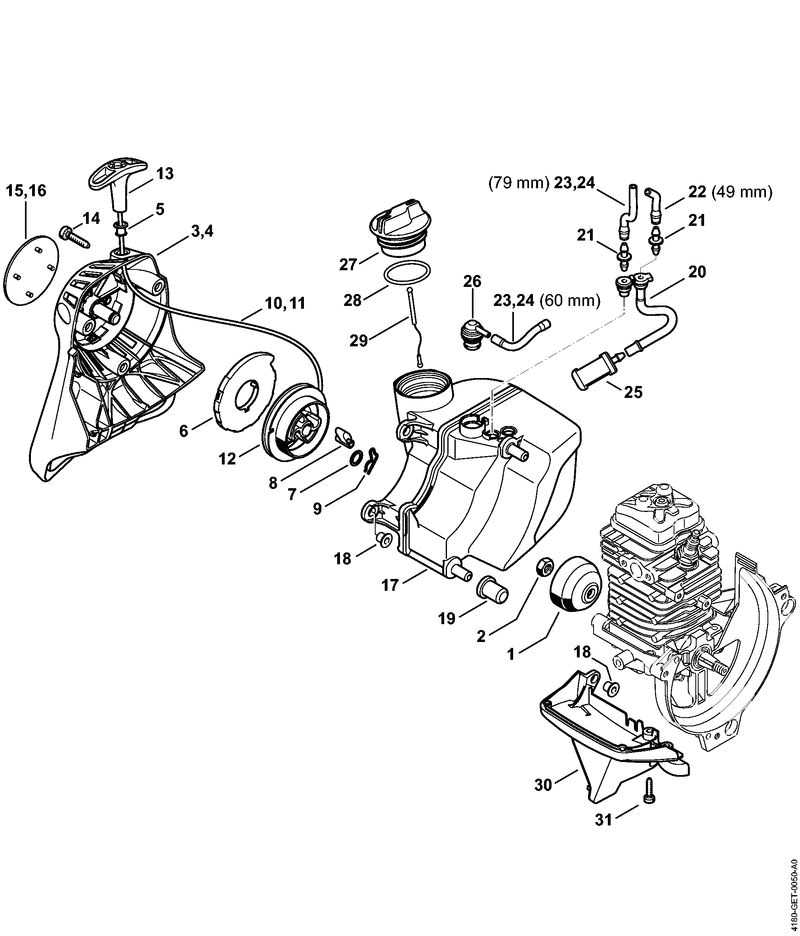

Detailed illustrations and schematics allow users to easily identify and troubleshoot components, making repairs and replacements straightforward. With the right information, you can confidently tackle maintenance tasks, improving both safety and functionality. Learning how to interpret these resources is key to keeping your equipment running smoothly.

Understanding the breakdown of each section is an essential step in mastering your device. With precise insights into individual parts, you can approach repair and maintenance tasks with clarity and accuracy, ensuring your tool continues to perform at its best. Familiarity with these layouts simplifies what may seem like complex work into manageable steps.

Understanding the Key Components of Your Equipment

Every outdoor tool or machine consists of several integral sections that work together to ensure optimal performance. To maximize the lifespan and functionality of your device, it’s essential to familiarize yourself with its structure and the role each component plays. This knowledge makes it easier to perform maintenance tasks and address any potential issues.

Primary Mechanisms and Functions

The primary systems within the device work in tandem to deliver smooth operation. Understanding how the engine, drive, and control units interact is crucial for diagnosing problems. Each mechanism is designed to complement the others, ensuring the machine operates with efficiency and precision.

Critical Elements for Maintenance

Certain sections of the tool require more frequent attention than others. These include moving parts, seals, and connections that can wear down with regular use. By identifying these key areas, you can focus on maintaining or replacing components as needed, reducing downtime and increasing overall performance.

Identifying Key Elements for Maintenance

Proper maintenance begins with recognizing which components need regular attention. By understanding which parts are most susceptible to wear and tear, you can focus your efforts on keeping the device in top condition. This proactive approach helps avoid unexpected failures and ensures the equipment continues to function effectively.

Key elements that often require monitoring include the motor, gears, and seals. These parts experience the most strain during operation and can deteriorate over time. Regular inspection of these sections will help identify any issues early, allowing for timely repairs or replacements. Additionally, checking moving parts for signs of wear ensures smooth operation and reduces the risk of malfunction.

How to Use the Schematic Effectively

A well-organized schematic is a powerful tool for understanding your device’s structure. By studying the layout of each component, you can easily identify and locate individual sections for maintenance or repairs. This approach allows for a more efficient troubleshooting process and better overall management of the equipment.

Understanding the Layout

Start by familiarizing yourself with the schematic’s organization. Each section typically includes labeled components, which can help you visualize how they interact. Pay close attention to the labeling of each part, ensuring you can quickly identify the right areas for inspection or replacement.

Utilizing the Schematic for Troubleshooting

When a problem arises, refer to the schematic to pinpoint the malfunctioning component. By understanding the connections between parts, you can easily isolate the issue. This systematic approach reduces guesswork, helping you fix problems more quickly and accurately.