When working with any outdoor machinery, having a clear understanding of its structure is crucial. Knowing how the different elements fit together allows for better maintenance, repair, and overall performance. By examining how each section functions, users can ensure their tools are running smoothly and efficiently.

Accurate knowledge of each individual component helps in identifying potential issues quickly. This guide is designed to provide a comprehensive breakdown of the essential parts and their roles, making it easier for users to handle any necessary adjustments or replacements.

Proper upkeep of your machinery is more than just a regular cleaning; it requires familiarity with its core components. By following the detailed instructions and understanding how everything works, you’ll be equipped to extend the life and reliability of your tool.

Understanding Stihl KM 91 R Components

Every piece of outdoor equipment is made up of several interconnected elements that contribute to its overall functionality. Understanding how these components work together allows for more efficient maintenance and problem-solving. Each section, whether it’s for power, control, or attachment, plays a vital role in ensuring the machinery operates effectively.

Familiarizing yourself with these components is essential for troubleshooting or performing routine care. Recognizing how each piece affects the overall performance enables users to make informed decisions when it comes to repairs or upgrades. When one component is out of place or not functioning as expected, it can impact the entire system, leading to inefficiency or even breakdowns.

By breaking down each individual component, users can gain insight into its function and importance. This knowledge helps with identifying wear and tear or potential issues before they become serious problems. Proper understanding also leads to smarter decisions when assembling or disassembling equipment for maintenance or transport.

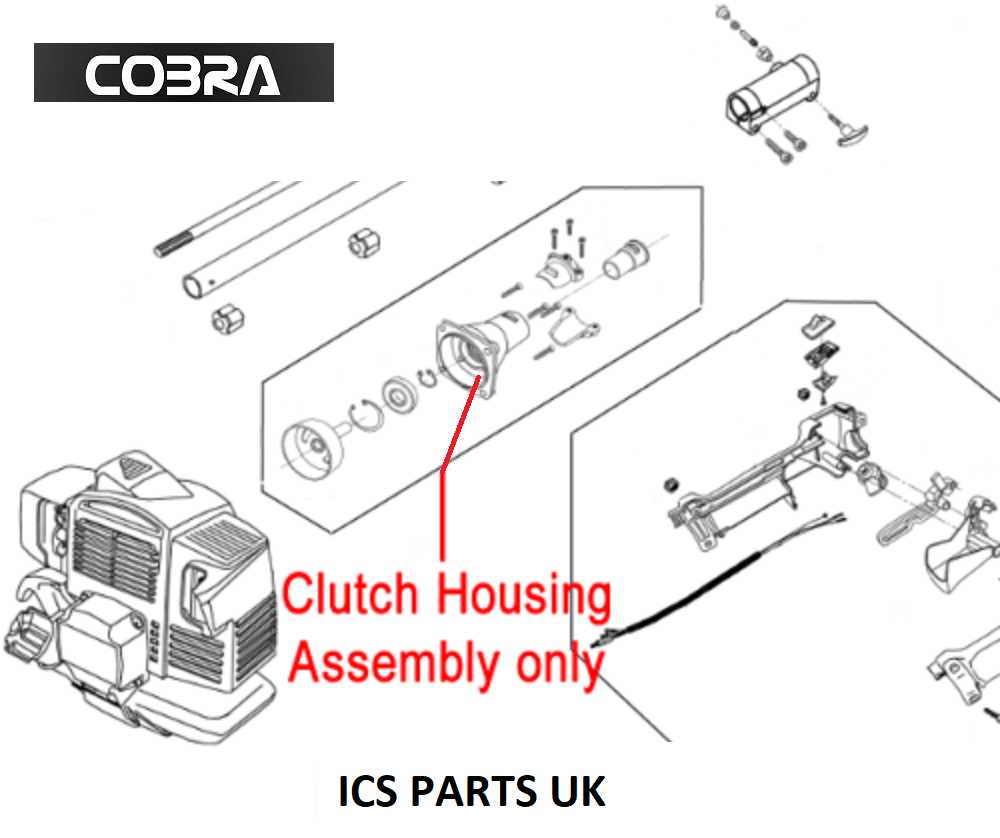

How to Read the Stihl KM 91 R Diagram

Understanding the layout of your equipment’s components is essential for proper maintenance and repair. By learning how to interpret the visual representations of these elements, you can quickly identify their locations and functions. This process simplifies any necessary repairs or replacements by offering a clear overview of how everything fits together.

Identifying Key Elements

The first step in reading the visual guide is identifying the main components. Focus on the larger sections that control the operation and overall performance of the tool. These include the engine assembly, power transmission elements, and attachments. Recognizing these primary parts helps create a foundation for further understanding.

Understanding Labels and References

Each part is typically labeled with a number or letter, which corresponds to a reference in the manual or list of specifications. These labels are essential for matching the visual representation to the actual components when you need to order replacements or track down a specific issue. Pay close attention to the numbering system and any accompanying notes to avoid confusion.

Replacing Parts on Your Stihl KM 91 R

When a component becomes worn or damaged, replacing it promptly is crucial to maintain the efficiency and longevity of your tool. Understanding the replacement process is essential for ensuring a smooth operation and avoiding unnecessary downtime. Whether you’re replacing a worn-out element or upgrading a specific section, following the correct procedure is key to successful repairs.

Start by ensuring you have the right replacement components before beginning the replacement process. Check the specifications to confirm compatibility. Disassemble the equipment carefully, making sure not to damage other parts during the process. Once the old component is removed, install the new one by following the instructions or referencing the equipment’s guide.

After replacing the necessary components, conduct a thorough inspection to ensure everything is properly assembled. Test the functionality of the tool to confirm the repair has been successful. Regularly replacing worn-out parts will not only improve the tool’s performance but also extend its operational life.