For any tool owner, understanding the layout and functionality of key components is crucial for efficient operation and long-term durability. Whether you’re repairing or maintaining your equipment, having a clear view of each part’s role helps in making informed decisions. With the right knowledge, even complex machines can be easily managed.

Every piece in a mechanical system plays a vital role, and identifying them accurately can prevent costly repairs and unnecessary replacements. By studying the breakdown of parts, users can improve troubleshooting and streamline maintenance processes.

Accurate identification of components ensures that you replace the right parts at the right time, avoiding unnecessary downtime. With a comprehensive understanding of the system’s structure, you can enhance both its performance and lifespan.

Understanding the Stihl KM94R Parts Layout

Having a clear understanding of a machine’s layout is essential for effective maintenance and repair. Each tool is made up of numerous interconnected elements, and recognizing how they work together helps prevent operational issues. Knowing the structure of these components aids in troubleshooting and ensures optimal performance over time.

Breaking down the structure of any device can often reveal its most vital elements. In this case, a detailed examination of the system’s construction will help you locate and identify the parts that require regular maintenance or replacement. Understanding the placement and interaction of each piece can reduce repair time and enhance the overall user experience.

Detailed exploration of the tool’s layout provides insights into how each component contributes to the function of the whole system. When performing routine checks or repairs, this knowledge ensures you’re addressing the right issues and prolonging the lifespan of your equipment.

Key Components of the Stihl KM94R

Understanding the main elements of any tool is essential for maintaining its efficiency and extending its lifespan. The most crucial components contribute to the overall functionality, ensuring smooth operation and allowing users to perform tasks without interruptions. Identifying and familiarizing yourself with these key parts is the first step toward effective tool care.

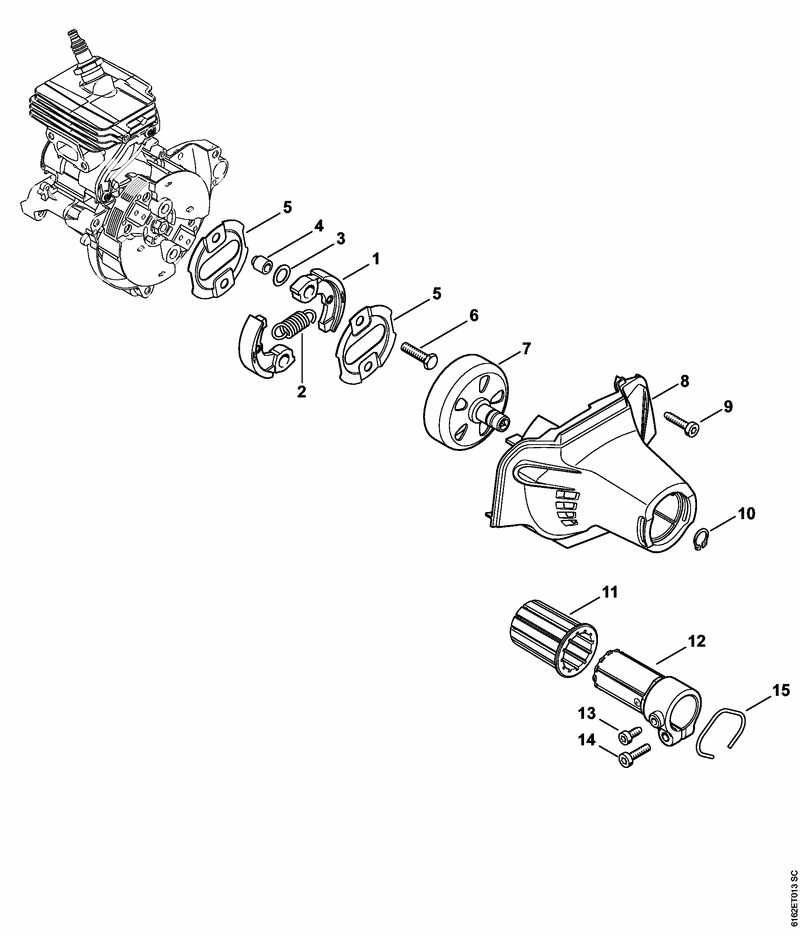

Engine and Power System

The engine serves as the heart of the machine, providing the necessary power for operation. It’s critical to ensure the engine is running smoothly, as any malfunction can cause significant performance issues. Key systems connected to the engine, such as the fuel system and ignition components, also play a role in maintaining overall functionality.

Handle and Control Mechanisms

The handle and control mechanisms are vital for comfort and safety during use. These elements are designed to provide the user with precise control over the machine while reducing fatigue. The ergonomic design of the handle and its associated control switches allow for a smoother, more efficient experience while working.

How to Use the Parts Diagram for Maintenance

Proper maintenance is key to ensuring the longevity and functionality of any mechanical device. A comprehensive layout of the tool’s structure can act as a valuable guide when performing routine checks or repairs. By understanding this visual breakdown, users can easily identify which components need attention and how to handle replacements or adjustments.

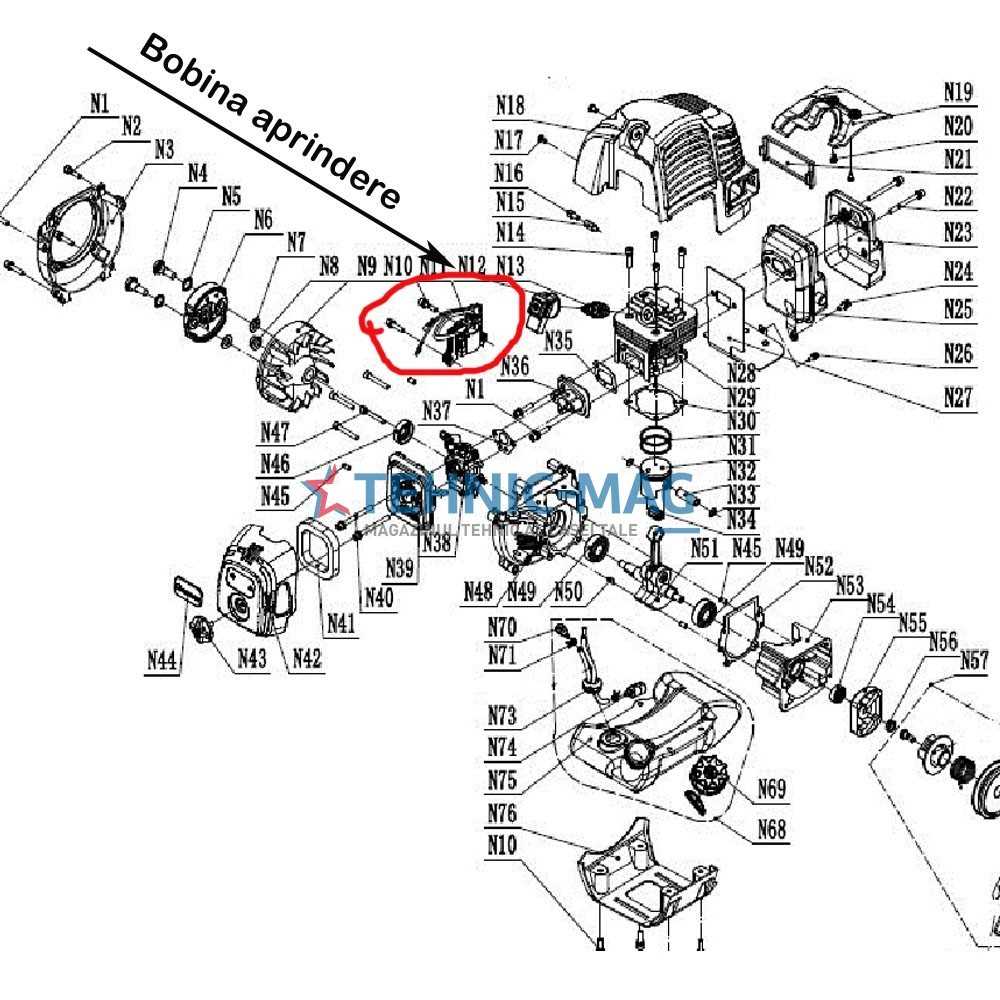

Identifying and Locating Components

One of the first steps in using a system’s layout for maintenance is recognizing and locating each key component. With a clear view of the tool’s internal structure, it’s easier to pinpoint areas that may require cleaning, lubrication, or part replacement. Familiarizing yourself with the locations of critical parts reduces the risk of errors during maintenance and minimizes downtime.

Effective Troubleshooting and Repair

When issues arise, the detailed layout can help you troubleshoot efficiently. By cross-referencing the problematic area with the diagram, you can identify the exact parts that might be causing the malfunction. Having access to a visual representation ensures you make precise repairs and replacements, saving both time and money in the long run.