When it comes to maintaining outdoor equipment, knowing the individual components is essential for ensuring smooth operation. With various models and designs, understanding the layout and function of each piece can make repairs and upkeep much easier. A clear understanding of how all parts fit together can save you time and money while ensuring better performance.

By familiarizing yourself with the detailed layout of your machine, you can quickly identify any issues that may arise. Whether it’s troubleshooting problems or replacing worn-out elements, knowing which parts are involved will help you take care of any challenges that come your way. In this guide, we will explore how to read and interpret the structure of your machine’s design for efficient maintenance.

Knowing the right terminology and part identification is vital when addressing repair needs. It allows for better decision-making when ordering replacements and understanding the overall assembly. As you continue to learn about each component, you will be able to approach repairs with confidence and skill.

Understanding Your Outdoor Equipment Components

Proper maintenance and efficient operation of any outdoor tool depend on a clear understanding of its individual elements. Each component serves a specific function and works together to ensure the overall machine runs smoothly. Recognizing these elements and their role in the mechanism will help you identify potential issues and address them promptly, leading to improved performance and durability.

Key Functional Elements

Every tool has essential components that drive its functionality. For example, the engine, fan, and air intake system all play crucial roles in creating the necessary force for operation. When one of these parts begins to wear out or malfunction, it can hinder the tool’s effectiveness. Knowing how these pieces interact can help you troubleshoot and make informed decisions when it’s time to replace or service specific parts.

Common Issues and Solutions

With regular use, some parts may experience wear and tear, leading to reduced performance or malfunctions. For instance, problems such as poor airflow, engine starting issues, or vibration irregularities can arise. Identifying which element is causing the issue is key. Routine checks and timely part replacements are vital in extending the lifespan of your tool.

Understanding the layout and functions of the various components ensures you are well-prepared to address any challenges and maintain optimal performance throughout the tool’s lifespan. Regular maintenance based on your knowledge of these elements will ultimately keep your equipment in top condition.

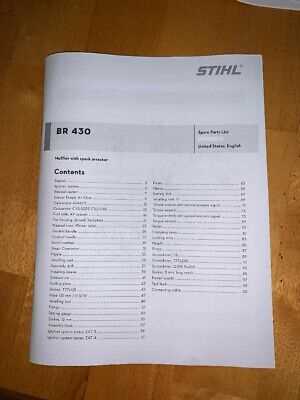

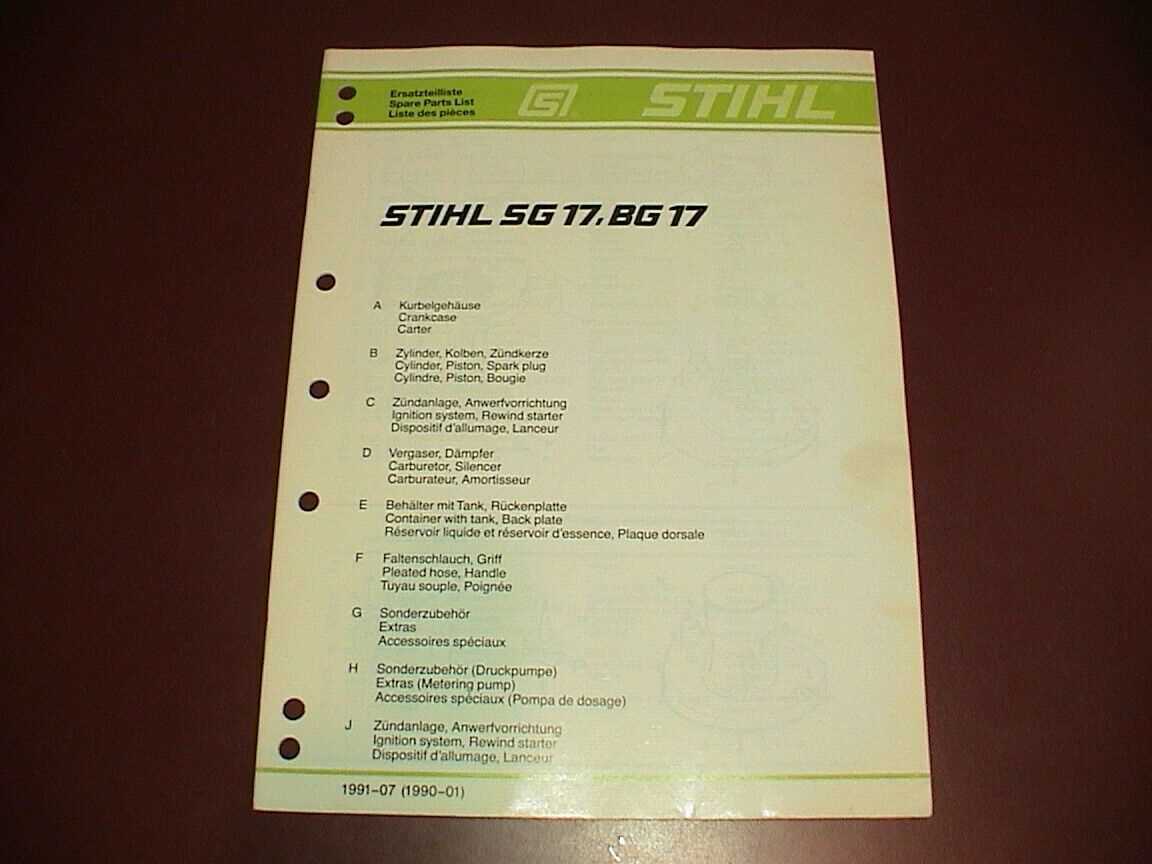

How to Use a Parts Diagram Effectively

Understanding how to read and interpret a technical visual representation of your equipment can significantly simplify repairs and maintenance. By using these illustrations, you can identify each individual component and its connection to the whole system. This guide helps break down the steps for effectively utilizing such visuals to enhance the repair process.

Start by familiarizing yourself with the layout. These visuals typically separate the parts into groups, making it easier to pinpoint where each element is located within the structure. Pay close attention to the labels, numbers, and descriptions provided alongside each part. This information is essential for identifying the correct replacements and understanding how each piece interacts with the others.

When working on repairs, use the visual as a reference for disassembly and reassembly. The clear depiction of each element ensures that you can follow the correct order and avoid errors. A well-executed reference can also guide you through complex troubleshooting steps, allowing you to focus on the parts that need attention. This method saves both time and effort by offering a clear and organized approach to maintenance tasks.

Common Issues and Replacement Parts for Outdoor Equipment

Over time, even the most reliable outdoor tools may experience wear and tear. Understanding the common issues that arise and knowing which components need replacing can save you both time and money. In this section, we will discuss some frequent malfunctions and the parts that are often responsible, along with how to address them efficiently.

Common Problems and Their Causes

One of the most frequent issues with outdoor equipment is poor airflow, often caused by clogged or damaged air intake components. This can significantly reduce the tool’s efficiency and performance. Another common problem is engine starting difficulties, which could be attributed to faulty spark plugs, damaged fuel lines, or clogged filters. Vibration irregularities or excessive noise might also occur, often due to worn-out or imbalanced fan blades.

Identifying and Replacing Damaged Components

Once the issue has been diagnosed, identifying the correct replacement part is crucial for effective repairs. For example, if the air intake is blocked, replacing the air filter or cleaning the intake system can restore functionality. Similarly, a faulty spark plug or worn fuel line should be replaced immediately to prevent further damage. Always use high-quality replacements to ensure optimal performance and extend the lifespan of your tool. Regular maintenance and timely part replacements will help keep your equipment running smoothly for years to come.