When maintaining a chainsaw, understanding its individual components is crucial for effective repairs and replacements. Knowing how each part functions helps in troubleshooting issues and ensuring the tool runs efficiently.

For anyone looking to perform repairs, it’s essential to familiarize yourself with the key elements that make up the machine. From the engine to the cutting mechanism, each component plays a role in the overall performance.

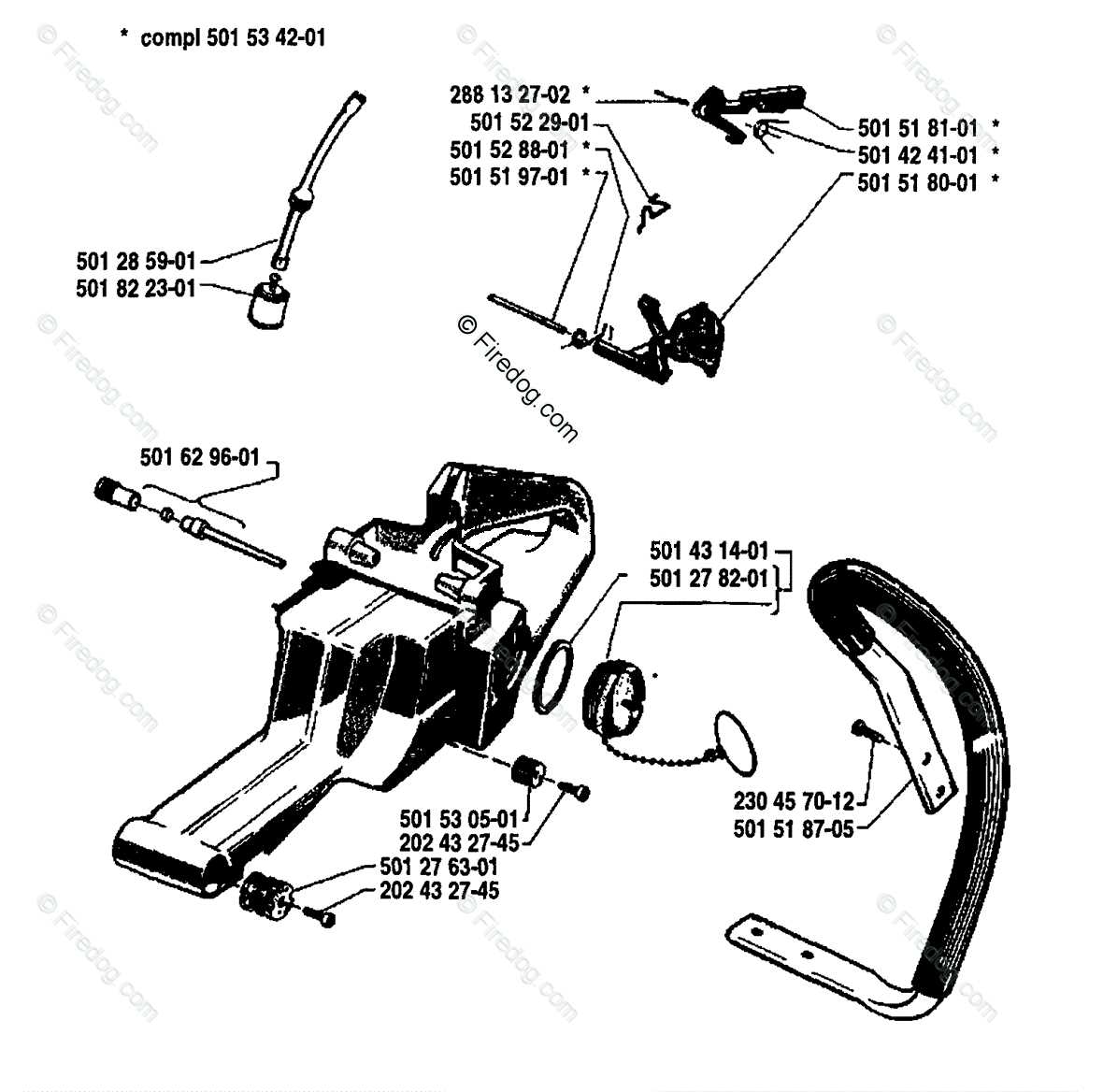

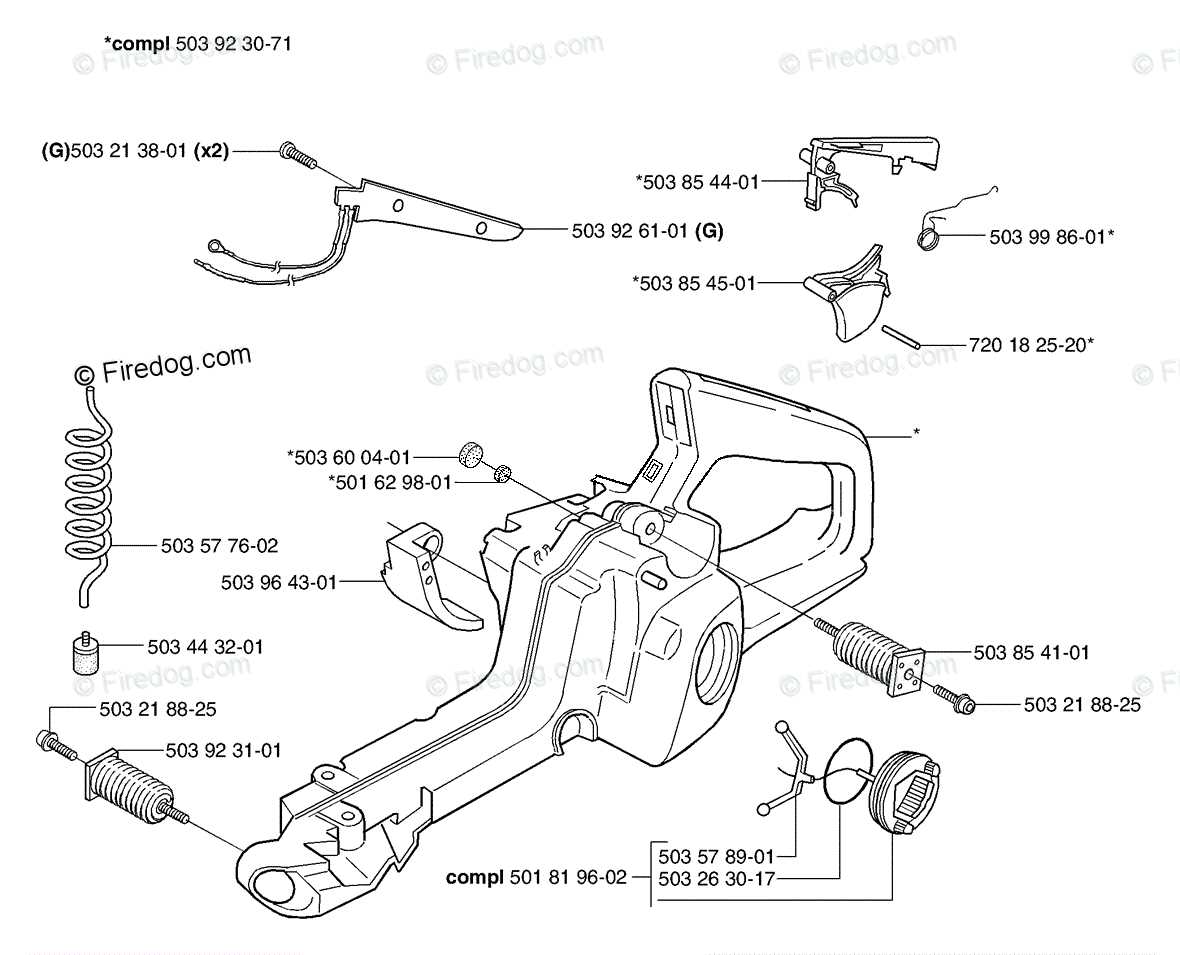

Having access to a detailed guide or reference of these parts allows for precise identification of damaged or worn-out elements, leading to quicker fixes. Whether you’re replacing a worn-out chain or cleaning the fuel system, understanding the structure can save both time and money.

Chainsaw Components Explained

Understanding the various components of a chainsaw is key to performing effective maintenance and repairs. Each element, from the engine to the cutting mechanism, plays an important role in ensuring smooth operation. A clear knowledge of these components will help you troubleshoot any issues and replace damaged parts accurately, allowing for optimal performance.

Engine and Power System

The engine is the heart of the chainsaw, responsible for providing the necessary power to drive the chain. It operates by converting fuel into energy, which is transferred to the chain through the clutch and sprocket system. Regular maintenance of the engine is crucial for longevity and reliability. Proper fuel mixtures and clean air filters are essential for ensuring consistent operation.

Cutting Mechanism and Safety Features

The cutting mechanism consists of several components, including the chain, bar, and sprocket. The chain rotates around the bar, allowing the saw to cut through wood. It’s important to keep the chain sharp and properly tensioned for efficient cutting. Additionally, safety features such as the chain brake and anti-vibration system help protect the user during operation. These elements work together to provide smooth and safe cutting experiences.

Understanding the Chainsaw Breakdown

To effectively maintain and repair a chainsaw, it’s essential to have a comprehensive understanding of how its components are organized and function together. A breakdown of the saw provides a detailed view of its inner workings, allowing for easier identification of each part and its role in the overall performance.

Each section of the chainsaw, from the fuel system to the cutting elements, serves a specific purpose. Recognizing how these parts interact helps users identify potential issues more quickly and make necessary repairs. Whether it’s adjusting the tension of the chain or replacing a worn component, a solid grasp of the saw’s breakdown is vital for successful maintenance.

How to Replace Chainsaw Components

Replacing individual components in a chainsaw is an essential skill for anyone looking to extend the life of their tool. Knowing how to properly replace worn or damaged parts ensures the machine continues to perform efficiently. With the right tools and approach, replacing components is a straightforward process that can prevent costly repairs down the line.

Step-by-Step Replacement Process

Before beginning any replacement, ensure the chainsaw is completely powered off and disconnected from any fuel source. Start by removing any covers or shields that protect the internal components. This may involve unscrewing or unclipping various parts to expose the damaged element. Once the broken or worn component is accessible, carefully remove it, making note of how it is installed for the new piece. After inserting the new component, reassemble the chainsaw and test it for proper function.

Common Replacement Tips

It’s important to use high-quality replacement components to maintain performance. When replacing cutting elements such as the chain, ensure it is the correct size and properly tensioned. Always follow manufacturer instructions for installation to avoid improper fitment, which can affect safety and efficiency. Additionally, keep tools clean and well-maintained to avoid introducing contaminants into the system during the repair process.