Every machine consists of numerous elements that work together to ensure smooth operation. A thorough understanding of these parts is essential for proper maintenance, repair, and optimization. Recognizing how each component fits into the overall structure allows users to identify potential issues and enhance performance over time.

Effective maintenance starts with having a clear view of the machinery’s internal structure. Whether you’re repairing a malfunction or performing routine checks, knowing the layout and function of each element is crucial. This knowledge helps prevent unnecessary repairs and prolongs the life of the equipment.

By gaining insight into how each component functions, you’re better equipped to tackle any challenges that arise. This guide will help you navigate the complexities of the system, making it easier to manage and maintain your tool efficiently.

Understanding Stihl MS 251 Components

To effectively operate and maintain any tool, it’s crucial to have a deep understanding of its internal structure. Each individual element plays a specific role, contributing to the overall functionality and efficiency of the machine. Knowing how these elements work together allows users to troubleshoot issues, perform repairs, and ensure smooth operation.

Breaking down the key components helps in identifying which parts require attention or replacement. With a comprehensive overview of the device’s construction, you can gain a clearer sense of its strengths and weaknesses. Regularly checking and understanding these elements reduces the risk of unexpected malfunctions and optimizes the tool’s lifespan.

Familiarity with the system ensures you’re prepared for routine maintenance and repairs. By recognizing the location and function of each part, you can tackle even the most challenging tasks with confidence. This section will explore the essential components of the machine and provide insight into their individual roles within the system.

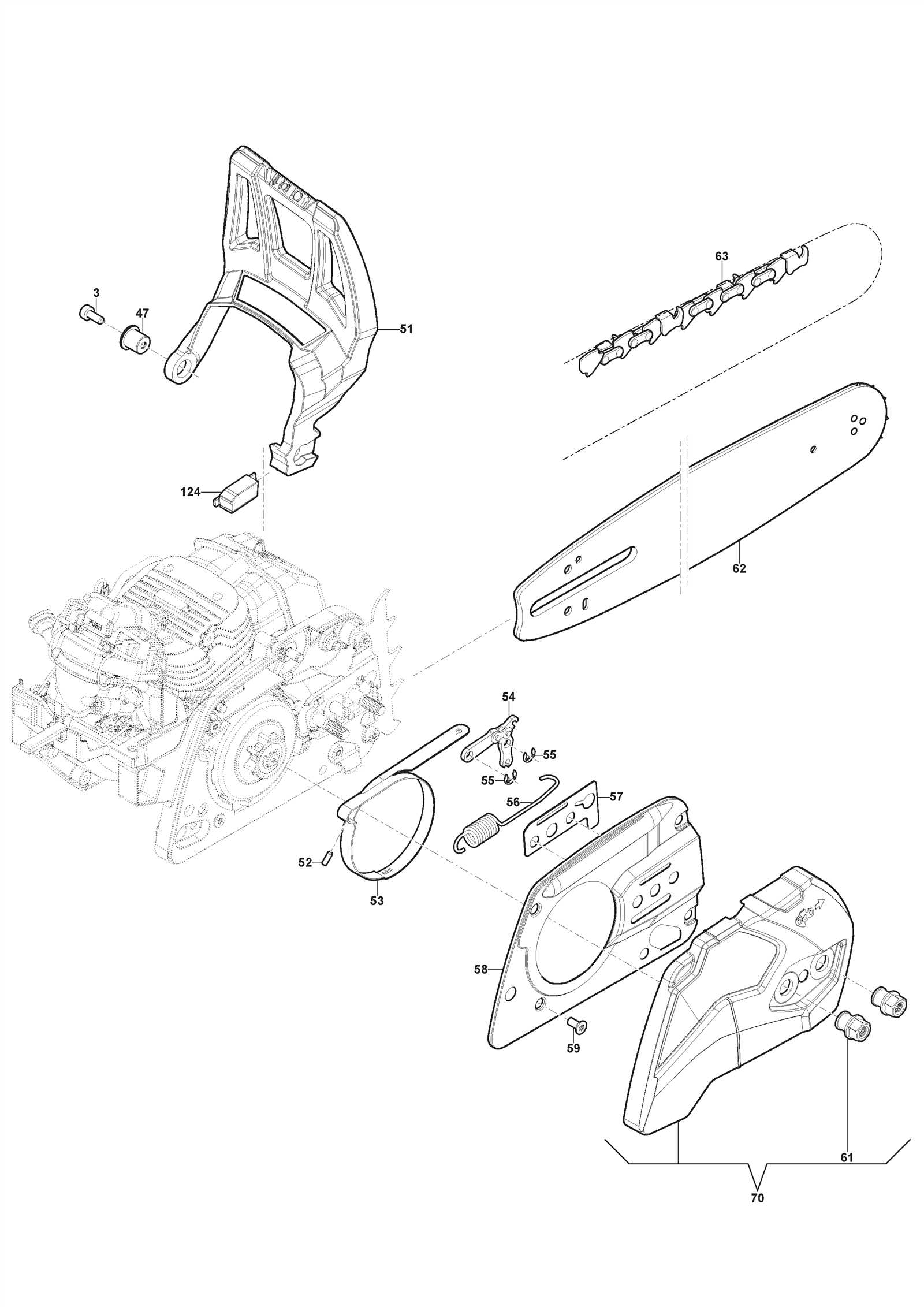

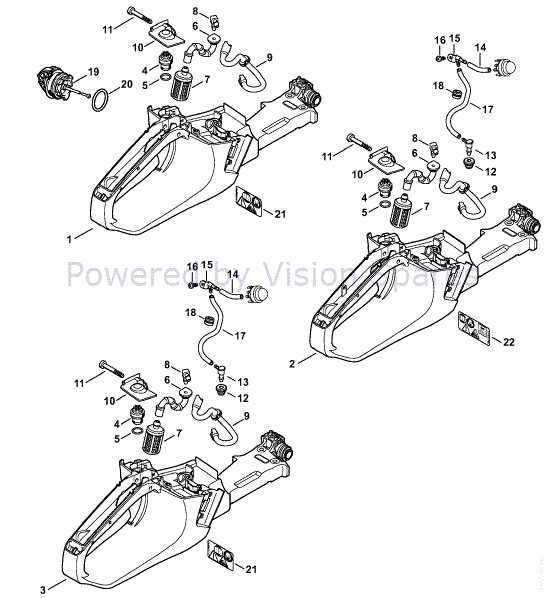

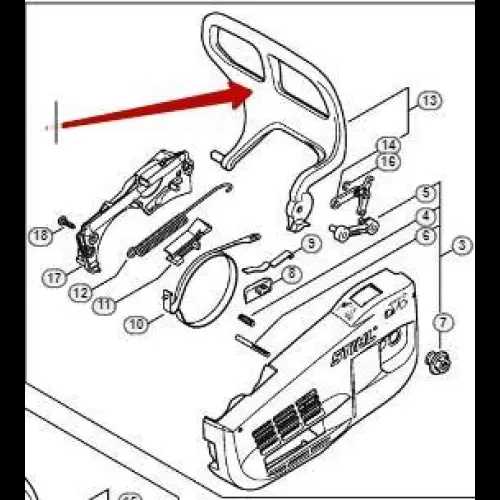

How to Read the Parts Diagram

Understanding the layout of any machinery’s components is essential for successful repairs and maintenance. A visual representation of the internal structure can provide crucial insights into how everything fits together. Learning to interpret these illustrations helps users easily identify which parts need attention and how to replace or service them effectively.

Interpreting the Labels and Symbols

Most schematics feature labels, numbers, or symbols that correspond to specific elements of the tool. These markings help you cross-reference parts with their descriptions in a manual or catalog. Being familiar with these codes allows you to quickly locate the components you need to work on or replace.

Understanding the Layout and Flow

The layout of the diagram is often arranged to show the flow and connection between components. Understanding how each piece interacts within the system is key to troubleshooting issues or performing upgrades. Recognizing the relationships between the various sections of the tool can save time when diagnosing problems.

Identifying Key Parts for Maintenance

Proper maintenance begins with knowing which components require regular attention. Some elements are more prone to wear and tear due to their constant use, while others may need occasional checks to ensure everything is functioning smoothly. Identifying these critical components allows you to focus on the areas that matter most, improving the tool’s longevity and performance.

Familiarizing yourself with these essential elements makes routine maintenance easier and more efficient. Regular inspection of high-wear parts such as the air filter, fuel system, and cutting components can prevent more significant issues from developing. By addressing small problems early, you can avoid costly repairs and downtime.

Understanding how each vital part operates within the system also aids in troubleshooting. Knowing which areas to inspect first during a malfunction will help you quickly pinpoint and resolve issues. With the right focus, maintenance becomes a straightforward task that enhances the overall performance of your equipment.