Proper understanding of your chainsaw’s construction is essential for efficient maintenance and troubleshooting. Knowing the individual elements and their functions allows for a smoother repair process and ensures your tool stays in top working condition.

In this guide, we will explore the various parts that make up this powerful machine. You will learn how to identify and replace worn components, as well as understand how each section contributes to the overall performance.

Whether you are performing routine maintenance or tackling more complex fixes, a clear understanding of the tool’s layout will help you work with confidence and precision. Taking the time to familiarize yourself with the internal mechanics will save you time and reduce costly repairs in the long run.

Understanding Chainsaw Components

Every chainsaw is made up of a series of interconnected parts, each contributing to its overall functionality. Understanding these elements and their roles is crucial for anyone looking to maintain or repair the machine effectively. By becoming familiar with each component, you can better assess its condition and identify areas that may require attention or replacement.

Key Components and Their Functions

The engine, bar, and chain are the primary components of any cutting tool, but there are many smaller yet equally important parts that work together to ensure smooth operation. The fuel system, including the carburetor and fuel lines, regulates power and efficiency, while the ignition system ensures reliable starting. The lubrication system keeps internal components running smoothly, reducing wear and tear during extended use.

Maintenance Considerations

Regular checks on each section of your tool can help prevent major breakdowns. Be sure to inspect the air filter, spark plug, and fuel system to keep the engine running at its best. Additionally, monitoring the tension and sharpness of the cutting chain, along with the condition of the bar, will improve both cutting performance and safety. Understanding these elements will enable you to address issues promptly before they cause significant damage.

How to Read the Component Breakdown

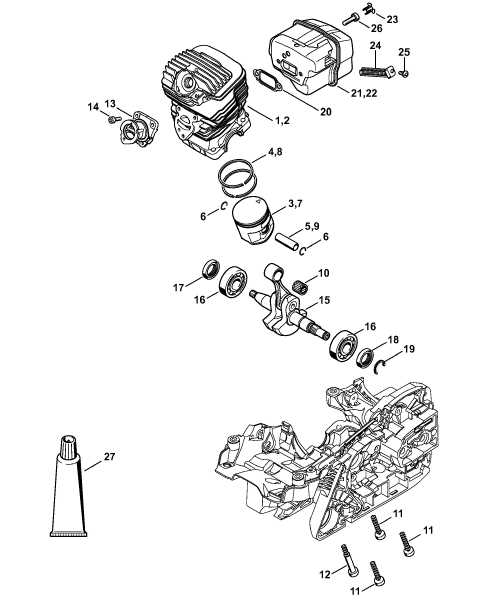

Understanding how to interpret a component breakdown is essential for anyone performing repairs or maintenance on their tool. A clear, well-structured diagram provides a visual representation of each element and how it fits into the overall assembly. By following these illustrations, you can easily identify parts, their placement, and how they interact with other sections.

Identifying Key Elements

Each section of the illustration typically labels individual components with numbers or letters, which correspond to a list of detailed descriptions. Familiarize yourself with the layout to quickly locate the items you’re working on. Pay attention to the surrounding context in the diagram, as it shows how each part connects to the rest of the machine, helping you visualize the assembly process more effectively.

Using the Breakdown for Repairs

When repairing or replacing components, refer to the breakdown to ensure you’re using the correct part number. The diagram will also give you insight into the necessary tools or procedures for disassembling the machine safely. By following these steps, you can confidently handle any repair, ensuring proper reassembly and smooth functionality of your tool after maintenance.

Common Repairs Using the Component Breakdown

When performing maintenance or repairs, having a clear visual reference of the tool’s construction is invaluable. It helps in pinpointing which components may need attention and understanding how to properly disassemble and reassemble each part. By using the breakdown, you can address common issues with greater accuracy and efficiency.

Replacing the Cutting Chain

One of the most frequent repairs involves replacing a dull or damaged cutting chain. The breakdown allows you to see the exact placement of the chain and its attachment to the bar. By identifying the chain tensioner and fasteners, you can easily remove the old chain and replace it with a new one. Ensuring correct tension after installation is crucial for safe operation.

Fuel System Maintenance

The fuel system often requires attention due to clogging or leakage. Using the reference guide, you can identify the fuel lines, carburetor, and filters. A blocked fuel line or dirty filter can hinder engine performance, and the breakdown will show you how to safely access and replace these components. Proper fuel system maintenance ensures optimal performance and extends the life of your machine.