Maintaining and repairing a chainsaw requires a clear understanding of its individual components and how they work together. Knowing the exact location and function of each part can greatly enhance the efficiency and lifespan of the tool.

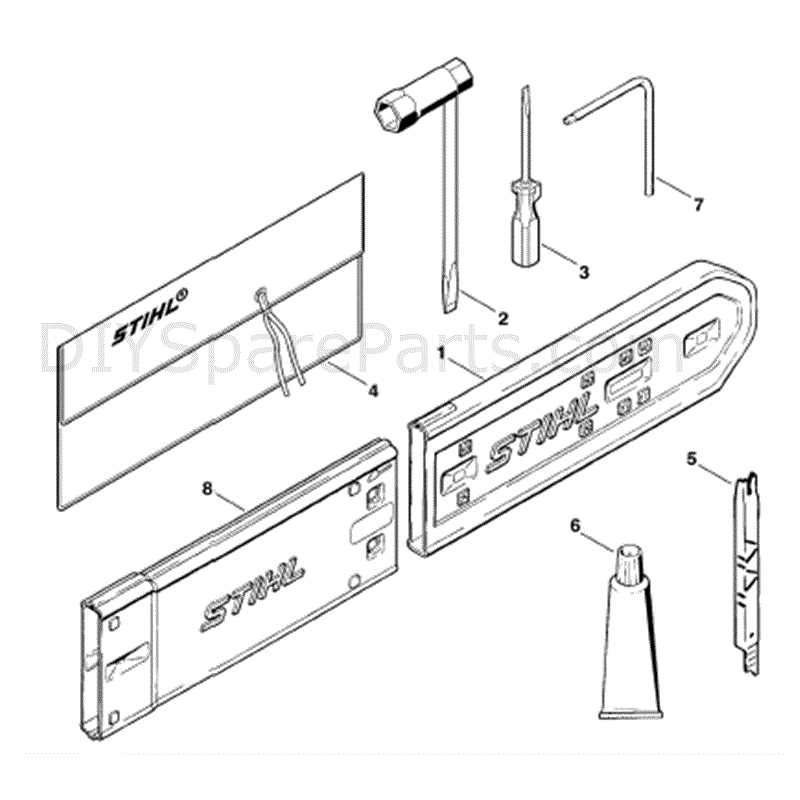

Proper identification of each element in the saw’s structure is crucial for performing repairs and routine maintenance. This knowledge helps users recognize signs of wear or damage and replace parts as needed.

Understanding the assembly ensures that users are able to handle any maintenance task, from simple adjustments to more intricate repairs. With the right information, keeping a chainsaw in optimal condition becomes a straightforward process.

Chainsaw Components Breakdown

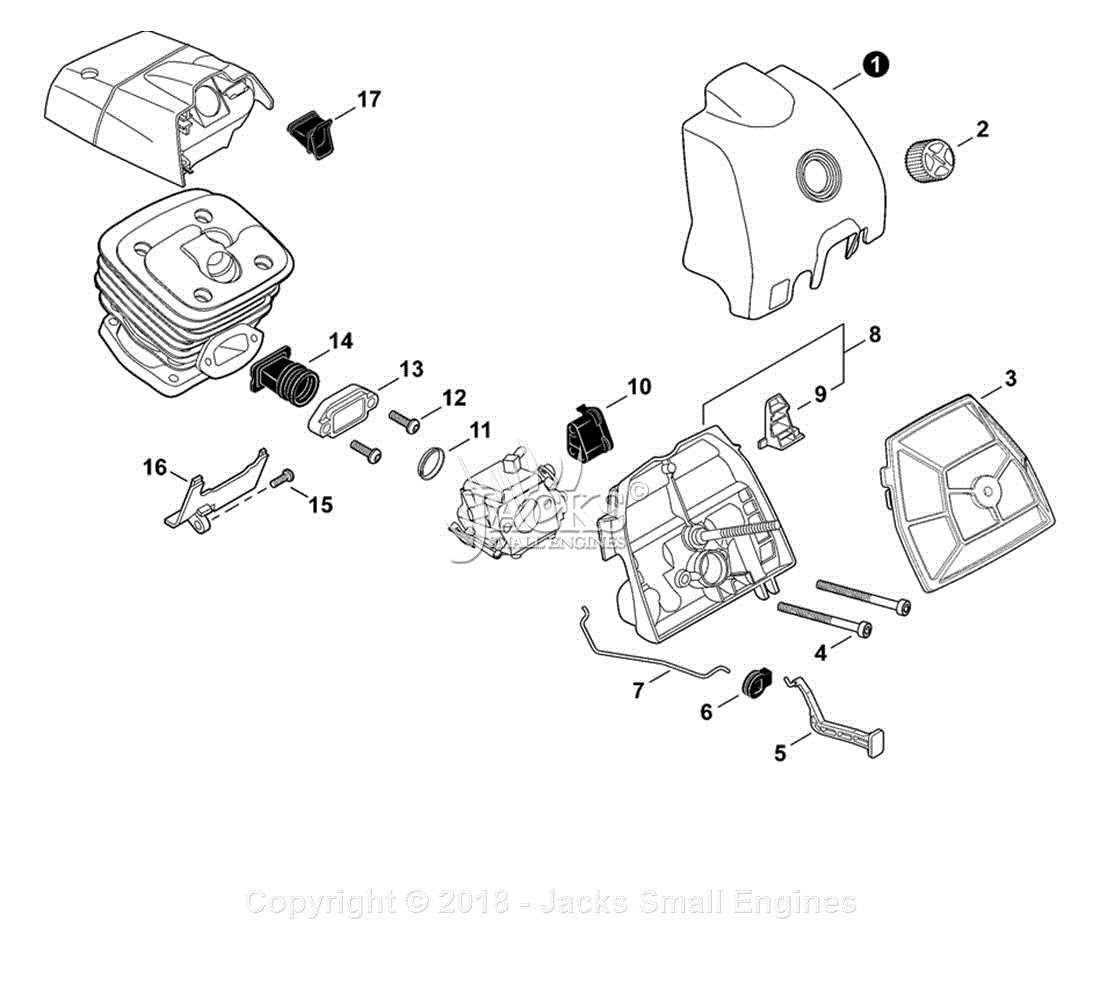

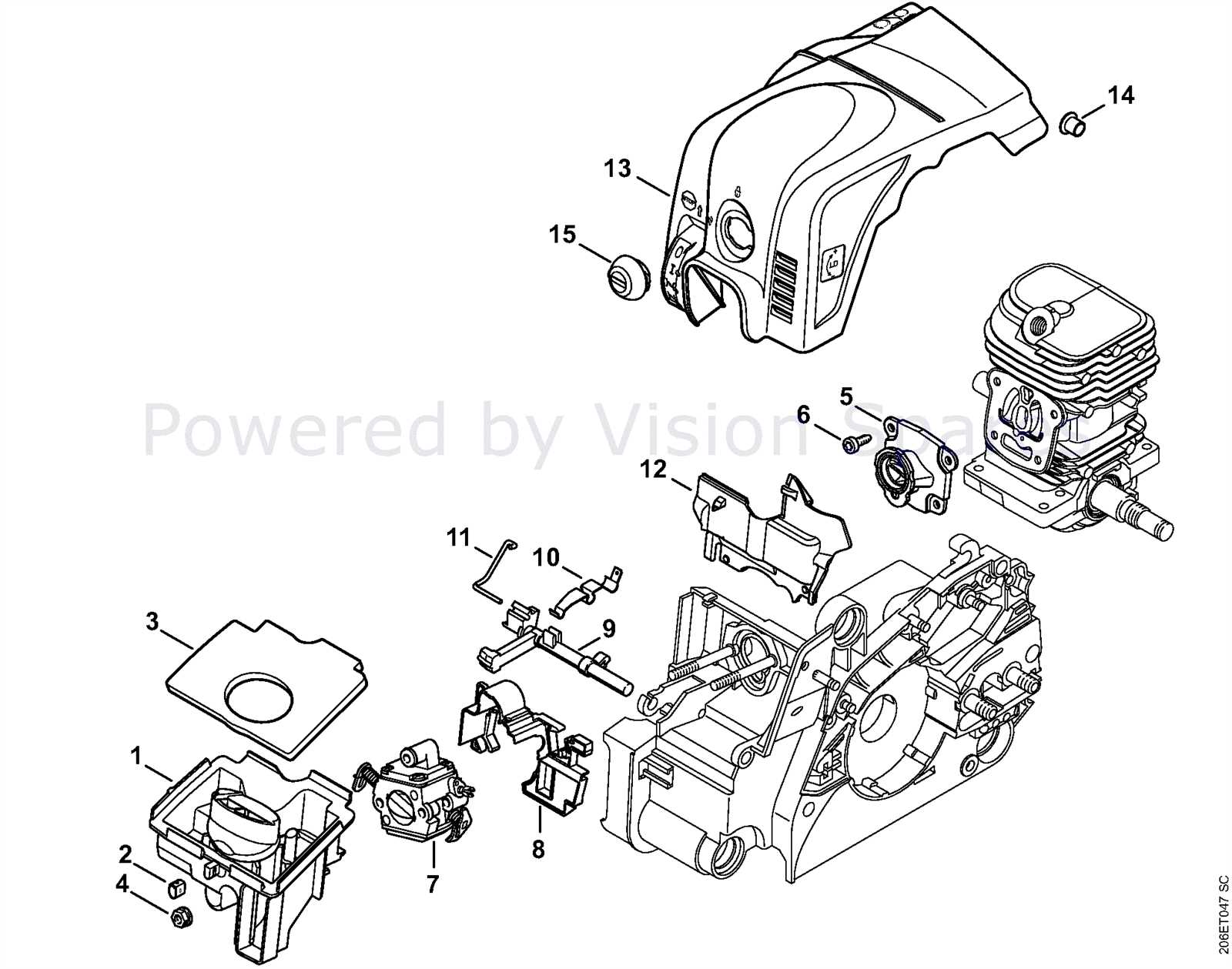

Understanding the inner workings of a chainsaw requires a closer look at its individual elements. Each component serves a specific purpose and contributes to the overall functionality of the tool. By breaking down the structure, users can gain insight into the design and operation of the saw.

Engine system, cutting mechanism, and safety features are among the key sections that make up the saw. Identifying and properly maintaining these parts ensures smooth operation and enhances the machine’s lifespan. For example, the engine system is responsible for powering the tool, while the cutting mechanism handles the actual sawing process.

Other critical elements include the fuel system, exhaust, and lubrication mechanisms, all of which play an essential role in maintaining optimal performance. Proper care and timely repairs of these components can prevent breakdowns and reduce the need for costly replacements.

Identifying Key Components for Repair

When it comes to repairing a chainsaw, knowing the most important components is crucial. Recognizing which parts are prone to wear and understanding their functions can make the repair process much smoother and more efficient.

Key sections such as the ignition system, fuel lines, and cutting chain are the most common areas requiring attention. These components are integral to the saw’s operation, and any issues with them can lead to performance loss or even complete failure.

In addition to the engine and cutting mechanism, the air filter and sprocket play vital roles in maintaining smooth operation. Regular checks of these elements help identify potential problems early, allowing for quicker repairs and preventing further damage.

Understanding the Function of Each Part

Each element within a chainsaw plays a crucial role in its overall functionality. Knowing how these components work together helps users understand how to operate and maintain the tool effectively.

Power System and Engine

The engine is the heart of the machine, converting fuel into energy to drive the cutting mechanism. The ignition system is responsible for starting the engine, while the carburetor mixes air and fuel for combustion. Understanding the power system is vital for troubleshooting performance issues.

Cutting Mechanism and Drive

The cutting mechanism, which includes the chain and sprocket, is responsible for the actual sawing action. The chain, driven by the engine, moves around the guide bar to cut through wood. Regular maintenance of these parts ensures the saw remains sharp and efficient.

Lubrication and cooling systems work in tandem to keep the machine running smoothly. While the lubrication system ensures the moving parts are well-oiled, the cooling system prevents overheating during prolonged use.