When maintaining or repairing any cutting tool, it’s crucial to have a clear understanding of its components. Knowing how each part fits together and functions will make the process of troubleshooting and assembly much easier. This knowledge ensures smooth operation and extends the lifespan of your equipment.

Component identification is key to recognizing potential issues before they escalate. Whether you’re dealing with wear and tear, or replacing a faulty piece, having a reference guide allows you to work with confidence. With the right tools and a clear understanding of your machine’s layout, performing repairs becomes a manageable task.

Regular maintenance can prevent major breakdowns. With a visual guide and some basic mechanical skills, even novice users can confidently handle essential repairs. Take the time to familiarize yourself with your tool’s inner workings, and you’ll improve its performance for years to come.

Understanding the Stihl MS 361 Parts

To properly maintain and repair your cutting tool, it’s essential to have a thorough understanding of its internal components. Each element plays a vital role in the overall functionality and performance of the machine. By familiarizing yourself with these key elements, you can easily diagnose issues and ensure efficient operation during use.

Key Components of the Machine

When examining the various sections of the equipment, there are several core parts to focus on. The engine, fuel system, and cutting mechanism are the most integral elements, each contributing to the machine’s power and precision. Understanding how these sections work together will give you a better sense of when to replace or repair specific components.

Importance of Regular Inspection

Frequent inspection of your tool’s internal components is crucial for its longevity. By regularly checking for wear or damage, you can prevent costly repairs and maintain optimal performance. Knowing what to look for and when to act will help avoid unexpected breakdowns and keep the tool running smoothly.

How to Read the MS 361 Diagram

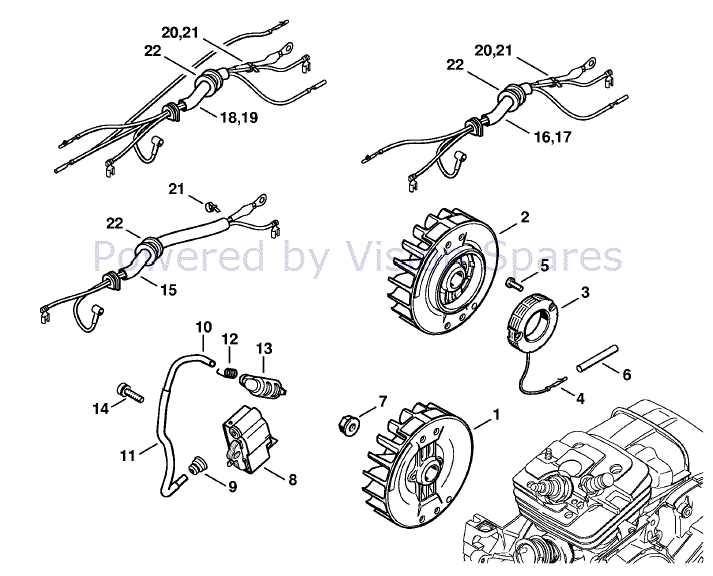

Understanding visual guides for your equipment’s components is essential for effective repairs and maintenance. These illustrations provide an organized view of how each element fits into the overall structure, allowing you to identify parts easily. Whether you’re looking to replace a worn-out piece or perform routine checks, knowing how to interpret these visuals will save time and ensure accuracy.

Decoding the layout begins with recognizing the different sections of the tool. Typically, each part is labeled with a unique identifier, making it easier to reference during repairs. Understanding these labels is crucial for pinpointing the exact component that needs attention.

Component grouping in the diagram is another helpful feature. Parts are often grouped according to their function within the machine, such as the power system, safety mechanisms, or cutting assembly. Familiarizing yourself with these groupings will help you focus on the specific areas that require your attention without getting overwhelmed by unnecessary details.

Common Maintenance Tips for Stihl MS 361

Proper care and maintenance of your cutting equipment are essential for ensuring its longevity and reliable performance. Regular upkeep prevents breakdowns, enhances efficiency, and ensures your tool works optimally throughout its lifespan. By following a few simple practices, you can extend the life of your tool and avoid costly repairs.

Regular Cleaning and Inspection

Routine cleaning of your equipment’s external and internal parts is crucial for maintaining smooth operation. Dust, debris, and residue can build up, affecting performance. Inspecting components such as the air filter, fuel lines, and spark plug regularly will help you identify issues early and keep the machine running at its best.

Lubrication and Tension Checks

Proper lubrication is key to maintaining the moving parts of your tool. Ensure that the chain and other critical components are well-lubricated to avoid excessive wear and overheating. Also, regularly check the tension of the chain and other adjustable parts to ensure they are properly set for optimal performance and safety.