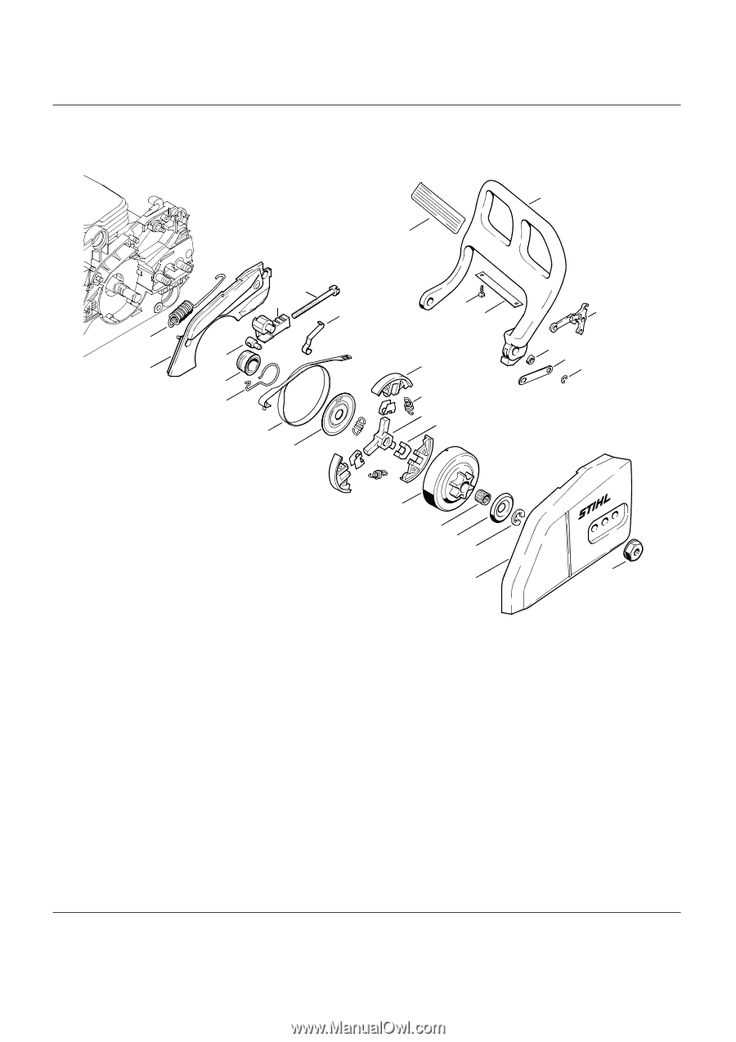

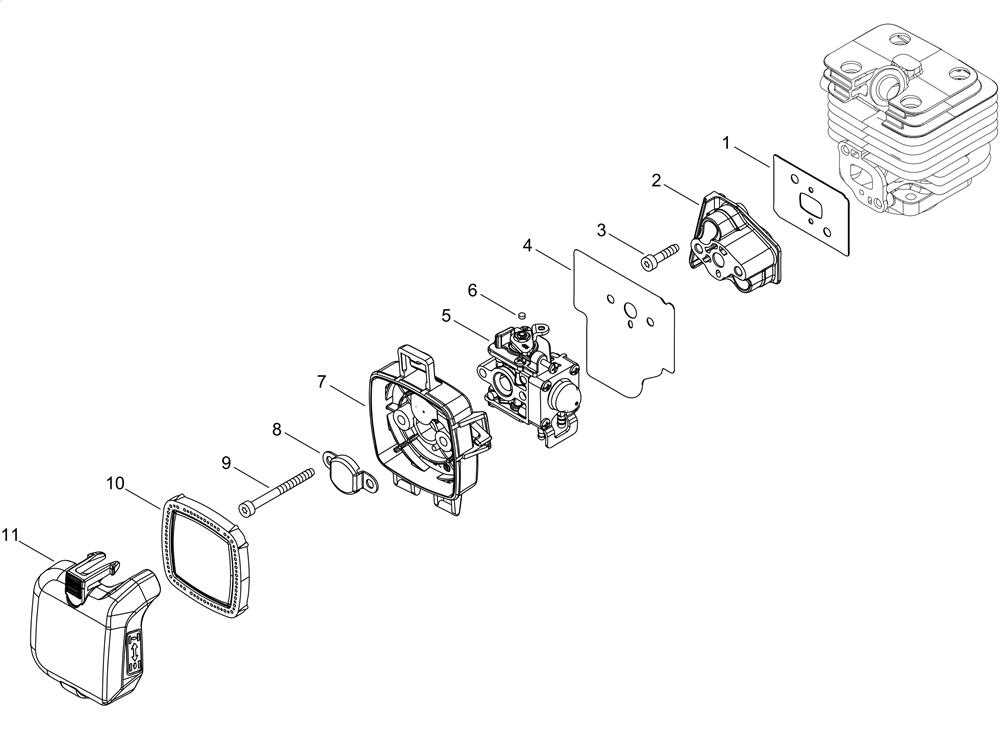

When maintaining and repairing any machine, having a clear view of its internal structure is essential. This guide will provide a closer look at the arrangement of essential elements, helping you identify each part and its role in overall functionality.

Knowing how to interpret the visual representation of these components can significantly simplify the repair process. Understanding where each piece fits and how they interact can prevent mistakes and ensure smoother handling during assembly and disassembly.

Proper identification of each part and its connections is critical for efficient maintenance and troubleshooting. Being familiar with the layout of these elements allows you to quickly spot wear or damage and make informed decisions on replacements or repairs.

Understanding the Component Layout

When working with any tool or machine, understanding how its parts are arranged is essential for effective operation and maintenance. Each element serves a specific function, and recognizing how they all fit together helps in troubleshooting and repairs.

The arrangement of these parts is designed to ensure smooth interaction between them, which is crucial for the machine’s performance. Knowing where each component is located and how it connects to the others is key to understanding how the system operates as a whole.

Having a clear overview of the component layout also makes it easier to spot potential issues. Whether it’s a malfunctioning element or a part that needs replacing, recognizing the structure of the system will allow you to quickly address any concerns and maintain optimal performance.

How to Read the Visual Breakdown

To properly interpret the visual representation of a machine’s components, it’s important to understand how the layout is organized. These illustrations provide a clear view of how parts are positioned and how they interact with each other.

Each section of the visual breakdown is usually labeled with identifying numbers or letters. These labels correspond to detailed descriptions of the components, making it easier to locate and understand each piece’s function within the assembly.

Familiarizing yourself with the symbols and notations used in the illustration helps you to identify key areas quickly. Once you understand the layout, you can more easily follow the connection between parts and troubleshoot any potential issues with precision.

Common Issues with Machine Components

When dealing with mechanical tools, it’s important to be aware of the most common issues that can arise within the internal structure. Over time, some components may experience wear and tear or malfunction, leading to performance problems.

Worn-out components are a frequent cause of issues. Parts that undergo frequent movement or friction tend to degrade faster, affecting overall functionality. Regular inspection can help identify these worn parts early, preventing further damage.

Another common problem is misalignment of parts. As the tool is used, vibrations and impacts can cause components to shift, which can lead to operational inefficiency or even failure. Ensuring everything is properly aligned is crucial for smooth operation.

Lastly, issues such as clogging or debris buildup in critical areas can cause disruptions in the tool’s performance. Regular cleaning and maintenance of these sections help prevent these problems and ensure that the equipment functions at its best.