When maintaining any complex machinery, it is essential to have a clear understanding of its internal structure. Each component plays a crucial role in ensuring the tool functions efficiently and safely. A thorough breakdown of all the parts can simplify repair and maintenance tasks, helping users identify any issues that may arise.

One of the most important aspects of such equipment is understanding how the individual elements fit together and work in unison. By examining a detailed schematic, users can quickly familiarize themselves with the names and locations of various components, improving their ability to troubleshoot or replace malfunctioning parts.

In this guide, we will explore the most common components, their purposes, and how they contribute to the overall operation of the machine. With this knowledge, you’ll be better equipped to maintain, repair, and extend the life of your equipment.

Stihl MS250 Chainsaw Key Components

Understanding the essential elements of any tool is crucial for efficient maintenance and repair. Each component has a distinct role that contributes to the overall performance, ensuring smooth operation. Knowing how these pieces fit together allows for a more precise approach when troubleshooting or performing routine checks.

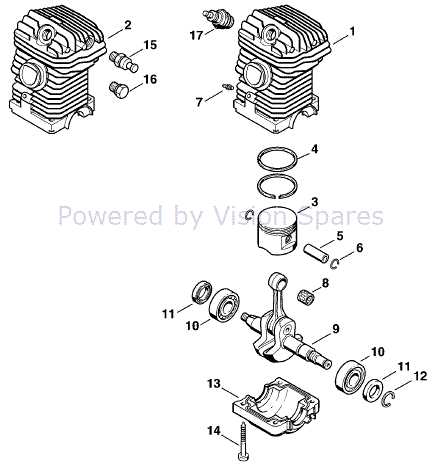

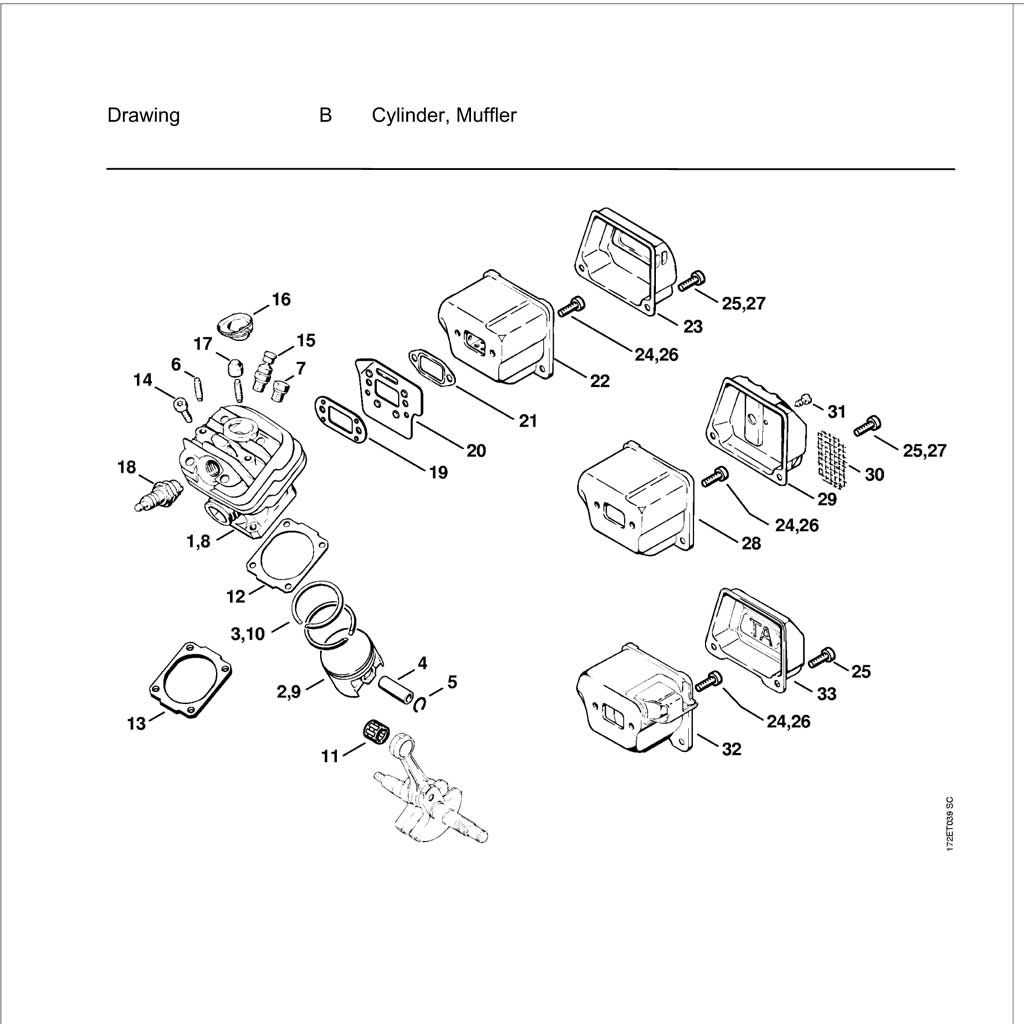

Engine and Drive Mechanism

The engine is the heart of the tool, responsible for generating the power required for operation. It works in tandem with the drive system, which transfers the engine’s energy to the cutting mechanism. A well-maintained engine ensures consistent performance and longevity of the entire system.

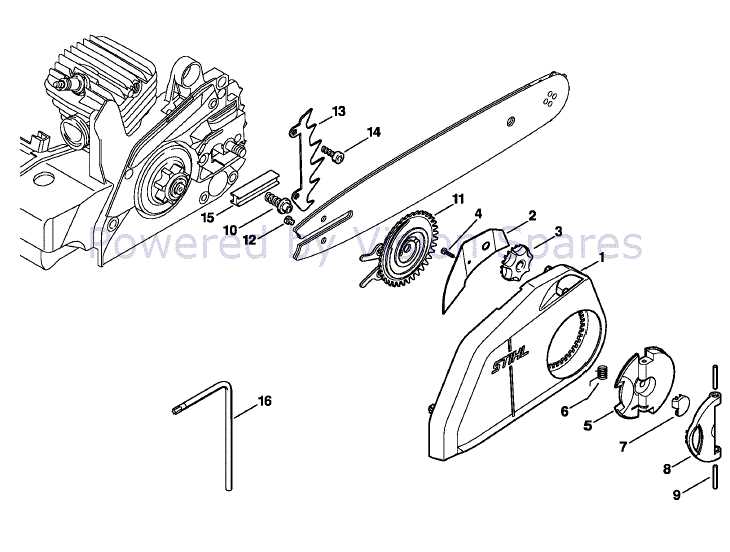

Cutting Mechanism and Housing

The cutting mechanism, typically composed of the guide bar and chain, is designed to efficiently cut through various materials. The housing serves as a protective casing, securing the cutting mechanism and other internal components. Regular inspection of these parts is necessary to prevent wear and ensure optimal cutting efficiency.

Understanding the Assembly of Stihl MS250

Proper assembly of any mechanical tool is essential for its effective operation. Each component must be installed in the correct order and securely fastened to ensure the system works efficiently. Understanding how these individual parts fit together can greatly improve the user’s ability to maintain and repair the tool.

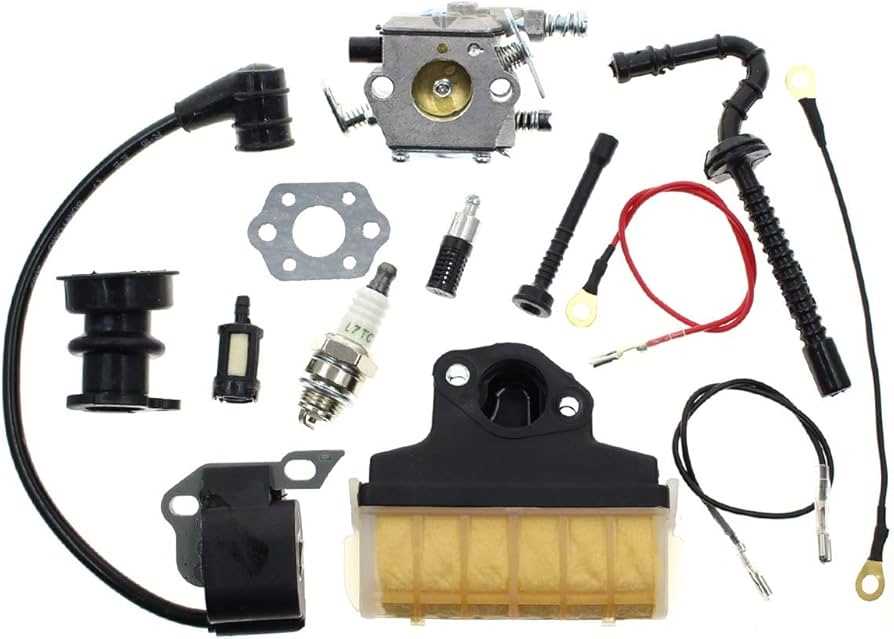

The assembly starts with the core components, such as the engine and its housing, followed by the attachment of the power transmission system. Once the main structure is in place, additional elements like the cutting mechanism, air filter, and safety features are added. Careful attention to each step ensures that no parts are overlooked, and everything functions as intended.

For those unfamiliar with the tool’s inner workings, a detailed breakdown can make the process much clearer. Familiarizing oneself with how the different parts connect allows for a smoother reassembly after maintenance or repair tasks.

Common Parts Issues and Solutions

As with any complex mechanical tool, certain components are prone to wear and tear over time. Understanding the common issues that may arise can help users identify and resolve problems efficiently. Regular inspection and timely intervention are key to preventing more serious damage and maintaining smooth operation.

Engine and Power Transmission Problems

One of the most frequent issues is related to the engine and power transmission system. These components are under constant stress and can sometimes fail due to improper maintenance or prolonged use.

- Issue: Engine failure to start or stalling during operation.

- Solution: Check the spark plug, fuel system, and ignition components. Replace damaged or worn parts as necessary.

- Issue: Lack of power during operation.

- Solution: Inspect the air filter and fuel lines for blockages or damage. Clean or replace as needed.

Cutting Mechanism and Safety Features

Another area where issues commonly arise is the cutting mechanism. Over time, the guide bar and chain can become dull or misaligned, reducing cutting efficiency and increasing the risk of accidents.

- Issue: Dull or damaged chain.

- Solution: Sharpen or replace the chain when it shows signs of wear.

- Issue: Misalignment of the guide bar.

- Solution: Ensure the bar is properly secured and aligned. If needed, adjust or replace it.