Understanding the intricate design of a chainsaw is essential for effective maintenance and repair. With many interconnected parts, it’s important to know how each component functions and how to identify them when replacement is needed. This knowledge can save time, reduce errors, and help ensure that the equipment operates at peak performance.

By breaking down the visual representation of each part and its placement within the machine, users can gain a clearer understanding of its assembly. Knowing what each piece looks like and how it interacts with others makes troubleshooting much easier and more efficient.

Identifying common issues becomes more straightforward when familiar with the essential components. It also ensures that parts are replaced correctly, improving longevity and reducing the likelihood of further damage or malfunction.

Understanding the Chainsaw Components

Every chainsaw is a complex machine with various components working together to ensure smooth operation. Familiarizing yourself with the essential parts helps you understand how they function individually and as part of the whole system. Whether you’re repairing, replacing, or maintaining a chainsaw, having knowledge of its components is crucial for success.

The engine, cutting mechanism, and safety features are among the primary areas to focus on when understanding a chainsaw. Each segment plays a significant role in performance and safety. Here are some key areas to consider:

- Engine assembly: This is the heart of the machine, generating the power needed for cutting.

- Fuel system: Components such as the carburetor, fuel filter, and fuel lines supply the engine with the necessary fuel mixture.

- Bar and chain: These are the cutting components, and their alignment and condition directly impact cutting efficiency.

- Ignition system: This system controls the spark necessary for combustion, ensuring the engine starts and runs smoothly.

- Safety features: Items like the chain brake, throttle lock, and handlebar help reduce the risk of accidents during use.

By learning how each part works, you can better assess when something needs to be fixed or replaced. A well-maintained chainsaw performs efficiently and lasts longer, making it a valuable tool for anyone working with it regularly.

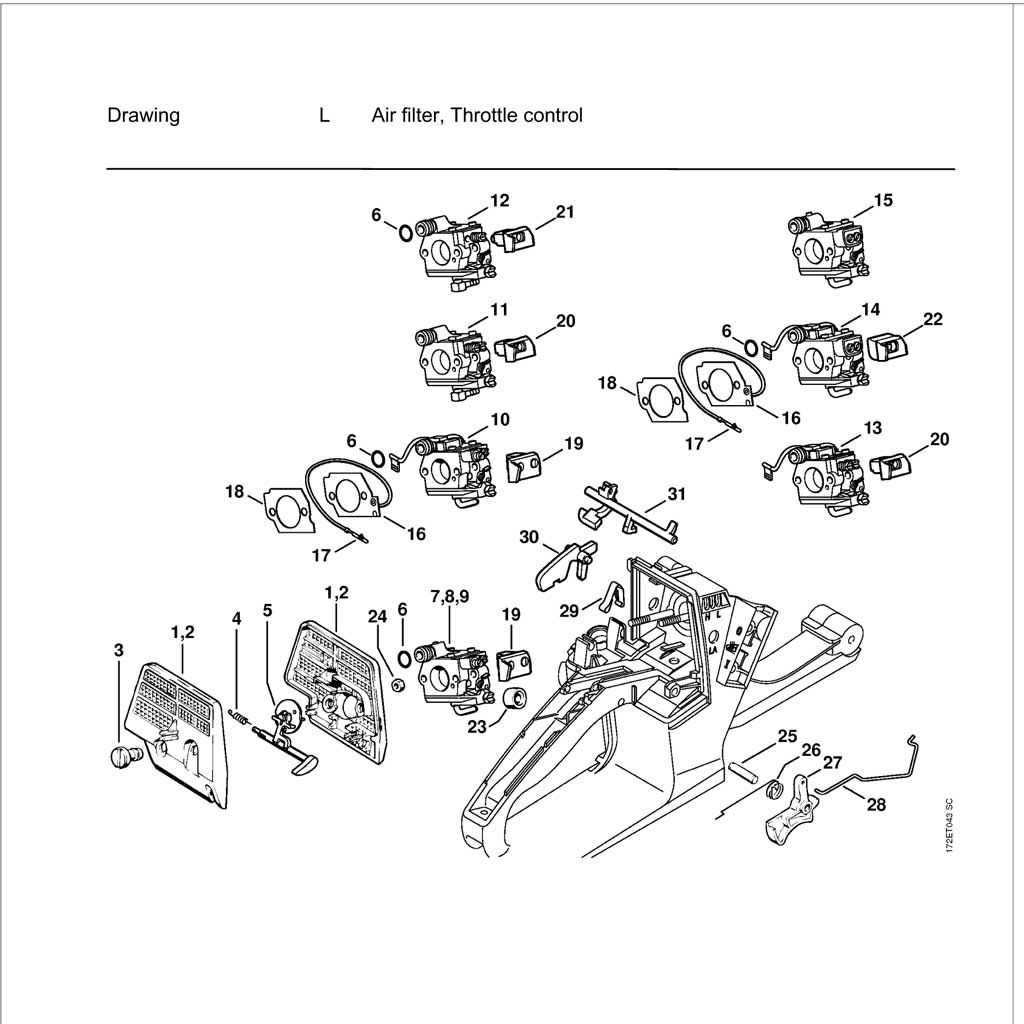

How to Read the Chainsaw Component Breakdown

Understanding a visual breakdown of a machine’s components can be a crucial step in maintaining or repairing it. These detailed illustrations offer a clear view of how each piece fits into the overall assembly. Reading and interpreting these visual guides ensures you can identify the correct parts, understand their functions, and know their placement.

To begin, focus on the main sections outlined in the diagram. Each part will be labeled with a number or identifier that corresponds to a detailed list. This list typically provides additional information such as part names, descriptions, and sometimes part numbers. Follow these simple steps to read the diagram effectively:

- Locate key components: Start by finding the major sections, such as the engine assembly or cutting mechanism, which will help you identify related components.

- Follow the numbering: Each part is assigned a specific number in the visual guide, which is referenced in the parts list for easier identification.

- Understand the connections: Observe how parts are connected to one another in the diagram, which will provide insight into their functionality and maintenance needs.

- Use the legend or parts list: This accompanying list helps explain each part in more detail, including any specific tools or procedures needed for replacement.

By mastering how to interpret these illustrations, you can quickly diagnose issues and understand which components need attention, ensuring your equipment runs optimally.

Common Chainsaw Replacement Components

Maintaining the functionality of your chainsaw often involves replacing worn or damaged components. Some parts are more prone to wear due to their frequent use or exposure to high stress. Knowing which parts to replace and how to identify them is crucial for keeping your tool in top condition.

Engine and Fuel System Components

The engine assembly, fuel system, and ignition parts are critical for the smooth operation of the chainsaw. Common components that may need replacement include:

- Carburetor: This part controls the fuel and air mixture and may need to be replaced if it becomes clogged or malfunctions.

- Fuel filter: The filter prevents debris from entering the fuel system and can become clogged over time.

- Spark plug: A worn or damaged spark plug can cause starting issues or reduce engine performance.

Cutting Mechanism and Safety Features

As the cutting components are subjected to the most stress, they often require attention or replacement:

- Chain: Over time, the chain can become dull, loose, or even damaged, affecting cutting efficiency.

- Bar: The guide bar may wear down with heavy use, leading to uneven cutting.

- Chain brake: This safety feature can wear out and may need to be replaced to ensure proper functionality.

By staying on top of these common replacements, you can prolong the life of your chainsaw and keep it running effectively for years to come.