Knowing the various elements that make up your equipment is crucial for its proper use and maintenance. A detailed illustration can help you identify each piece and understand how everything works together efficiently. This knowledge empowers you to handle repairs, perform routine checks, and ensure longevity in your machine’s performance.

Maintenance and proper care go hand in hand with a clear understanding of your tool’s layout. Whether you’re troubleshooting a malfunction or performing a simple cleaning, having access to an accurate representation makes tasks much easier and more effective.

In this guide, we’ll explore the key components, how to identify them, and why each part is important for smooth operation. By familiarizing yourself with this information, you can ensure your equipment remains in top condition, ready for any task at hand.

Understanding Your Tool’s Key Components

Every tool is built with a series of interconnected elements, each serving a specific function to ensure smooth operation. Understanding these individual components allows you to better manage your equipment, diagnose issues, and perform maintenance tasks with confidence. From the core mechanism to the smallest features, each part plays a role in the tool’s performance and efficiency.

When you familiarize yourself with the internal layout and function of these components, you gain a deeper insight into how the tool operates. This knowledge is vital not only for troubleshooting but also for optimizing its lifespan. In addition, knowing the key sections can help when seeking replacements or upgrades.

In the following sections, we will delve into the essential elements that contribute to the overall functionality of your machine. Understanding their purpose and how they fit together will give you a complete picture of the equipment and improve your ability to maintain it effectively.

How to Identify Components on the Layout

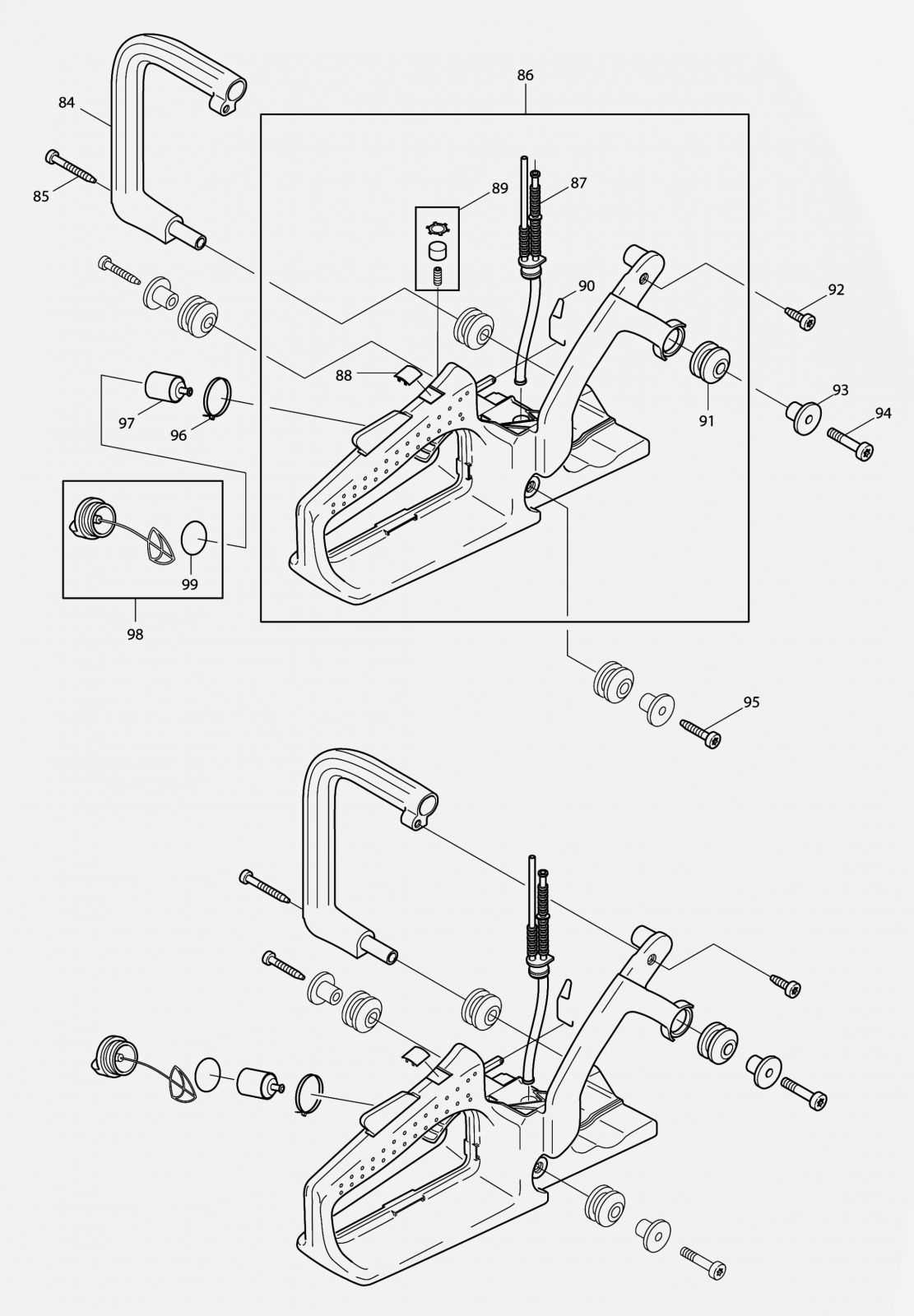

Recognizing and distinguishing the various elements of your tool requires understanding how to read and interpret its visual representation. By carefully studying the layout, you can pinpoint each individual piece and understand its role within the system. This process makes it easier to address issues, perform repairs, and ensure all parts are functioning properly.

Step-by-Step Identification Process

Begin by familiarizing yourself with the overall structure of the visual guide. Look for labels or numbers next to each component, which help to clearly identify the part. Each section of the image typically corresponds to a specific area of the tool, such as the motor, handle, or housing. By cross-referencing these labels with the tool’s manual or specifications, you can gain clarity on each piece’s function.

Common Mistakes to Avoid

When identifying parts, ensure you don’t confuse similar-looking elements, especially in intricate layouts. Pay close attention to sizes and shapes, as these can vary across different models. A proper understanding of the labels and their corresponding locations will help you avoid misidentification, making repairs and maintenance tasks smoother and more efficient.

Key Maintenance Tips for Your Tool

Proper upkeep is essential for keeping your equipment running efficiently and extending its lifespan. Regular maintenance ensures optimal performance, reduces the risk of malfunctions, and can prevent costly repairs in the future. By following a few simple guidelines, you can keep your tool in top shape, ready for use whenever you need it.

Start with routine checks, such as inspecting for wear and tear on key components. Clean your tool after each use to remove debris and prevent the buildup of dirt, which can affect its functionality. Always ensure the moving parts are well-lubricated to avoid friction and overheating, which can lead to damage over time.

Additionally, make it a habit to tighten screws and fasteners, as they can loosen with regular use. Pay close attention to the fuel system and replace any filters or components that show signs of deterioration. Keeping track of these simple yet important tasks will go a long way in preserving your tool’s performance and ensuring a longer lifespan.