Understanding the intricate details of your equipment’s structure is crucial for efficient operation and timely repairs. Knowing how each part fits together helps in maintaining peak performance and extending the lifespan of your machine. This guide will assist you in familiarizing yourself with the key elements of your chainsaw and how they interact.

By examining the detailed breakdown, you’ll gain insights into the specific components that require regular attention. Whether you’re performing routine maintenance or dealing with a malfunction, having a clear understanding of the inner workings can save both time and effort.

Proper knowledge of machinery components not only enhances your confidence in handling repairs but also ensures that you can make informed decisions when replacements are needed. This section aims to simplify the process by providing an easy-to-follow explanation of how each part functions within the overall system.

Understanding Chainsaw Components

Every machine is made up of several critical elements that work in unison to ensure its smooth operation. These components, ranging from the power system to the cutting mechanism, each serve a specific function that contributes to the overall efficiency of the tool. Familiarity with these parts is essential for proper maintenance and repair, allowing users to diagnose issues quickly and accurately.

Main Functional Parts

The main parts of a chainsaw include the engine, fuel system, and cutting equipment. The engine powers the entire machine, while the fuel system ensures a steady supply of energy. The cutting mechanism, often referred to as the bar and chain, is responsible for executing the actual work. Understanding how these elements interact will help you identify the most common areas where issues may arise.

Supportive Components

In addition to the primary functional parts, various supportive components, such as the air filter, ignition system, and safety features, ensure smooth operation and user safety. The air filter prevents dirt and debris from entering the engine, while the ignition system is responsible for starting the engine. These smaller parts, though often overlooked, play an equally important role in keeping the chainsaw running efficiently.

How to Read a Machine Breakdown

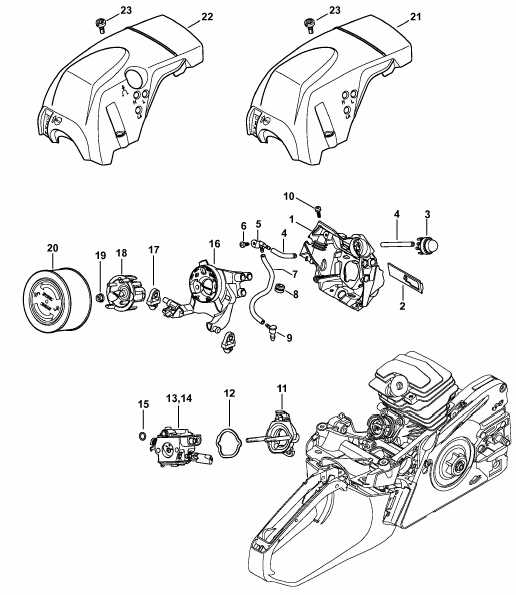

Interpreting a machine breakdown is essential for understanding how each component fits into the overall system. These visual guides provide a clear representation of where each element is located and how it connects with others. By familiarizing yourself with these illustrations, you can easily identify the parts in question, which will be crucial when performing maintenance or repairs.

The key to reading these breakdowns lies in recognizing the symbols, numbers, and labels that correspond to specific components. Each part is typically numbered, with a corresponding list that provides the part’s name and function. Understanding this reference system allows you to quickly identify the component you need to inspect or replace.

Common Repairs for Chainsaw

Regular use of machinery can lead to wear and tear, often requiring repairs to maintain optimal performance. Knowing the most common issues and how to address them can save time and ensure your tool runs smoothly. This section will guide you through the typical repairs and troubleshooting steps needed for common problems.

Here are some of the frequent repairs that may be required:

- Fuel System Issues: Over time, fuel lines and filters can become clogged or damaged, leading to engine performance problems.

- Chain Tensioning: A loose or overly tight chain can cause difficulty in cutting or even damage the bar and engine.

- Air Filter Maintenance: A dirty or clogged air filter can reduce engine efficiency and cause overheating.

- Starter Rope Repair: If the starter rope becomes frayed or snapped, it will need replacement to ensure proper ignition.

- Ignition System Problems: Faulty spark plugs or ignition coils can result in difficulty starting the machine.

Addressing these common issues promptly will help prevent more serious damage and extend the life of your tool. Always refer to the user manual for specific instructions on how to carry out these repairs.