Every machine is built with a variety of interconnecting elements that work together to achieve optimal performance. Knowing how these parts interact and understanding their roles can help ensure smoother operation and easier maintenance. This section aims to provide a comprehensive look into the core components of your saw, offering insight into how each piece contributes to the overall function.

Accurate identification of each component is crucial for troubleshooting, repairs, and regular upkeep. By learning the key features of the system, you’ll be better equipped to handle repairs or replacements, reducing downtime and extending the life of the equipment.

Proper maintenance can help prevent costly repairs and keep the saw running efficiently. Understanding the essential elements and their connections is an important step in maintaining your tool’s longevity and performance.

Understanding the Chainsaw Components

Every tool has several interconnected elements that play specific roles to ensure the proper operation of the machine. Understanding how these parts fit together and work in harmony is essential for both troubleshooting and maintenance. The success of your tool depends on the efficiency of each component, and knowing each part’s function can help optimize its performance over time.

Key Elements of the Assembly

The main parts of the tool consist of critical elements such as the engine, fuel system, and drive mechanisms. Each of these is essential for generating power, transferring energy, and ensuring smooth cutting. Recognizing the function of each part allows you to address issues quickly and confidently. The interaction between these components directly influences the tool’s overall functionality, making their understanding vital for maintaining long-lasting operation.

Maintenance Tips for Longevity

Regular care is key to ensuring that the components remain in good condition. Simple tasks, such as cleaning air filters, checking for wear, and lubricating moving parts, can prevent damage and reduce the need for major repairs. Understanding the role of each component enables you to perform focused maintenance tasks, ultimately extending the life of your equipment and keeping it running at its best.

Detailed Breakdown of Each Part

Every machine consists of several key elements, each contributing to its overall performance. By breaking down these components, it becomes easier to understand how the system functions and how each part supports the tool’s operation. A clear understanding of the individual components ensures effective troubleshooting and enhances the ability to perform maintenance tasks when needed.

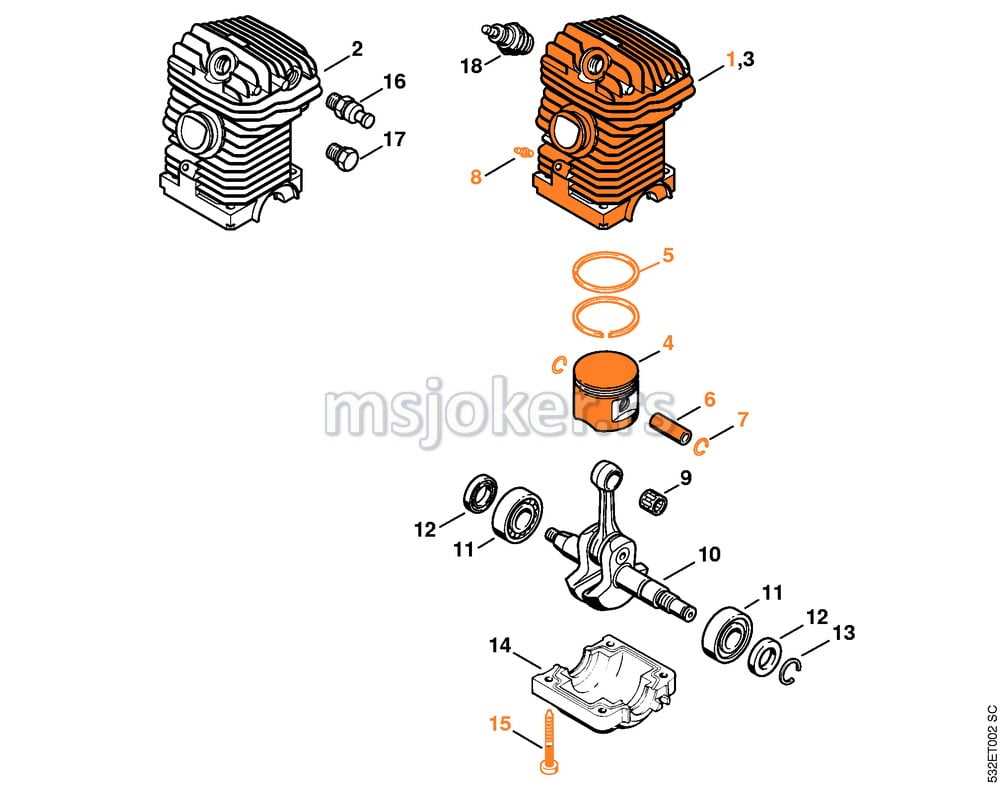

Essential Power and Drive Components

The engine and drive components are at the core of any chainsaw, responsible for generating the power required for cutting. The engine is powered by a combination of fuel and air, which is then converted into mechanical energy. The drive mechanism, which includes parts such as the clutch and sprocket, transfers that energy to the cutting chain, enabling it to move at high speeds. Regular inspection and maintenance of these components are essential for maintaining performance and avoiding breakdowns.

Control and Safety Features

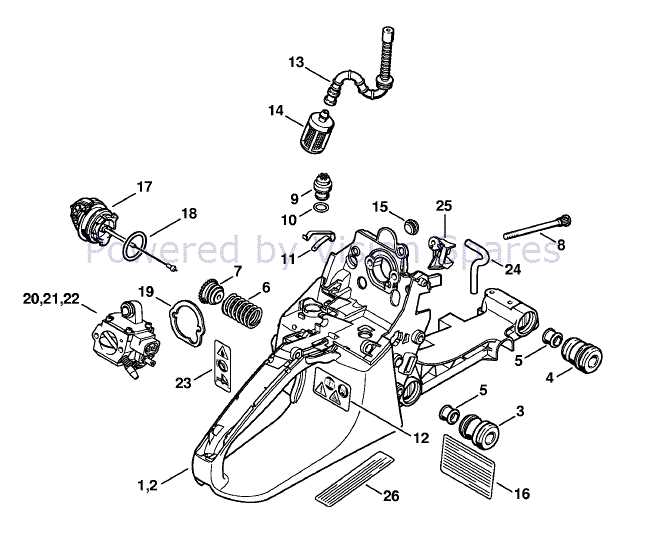

In addition to the core functional components, control and safety mechanisms play a critical role in ensuring the user’s safety and comfort. These include the throttle, trigger mechanism, and safety handles. The throttle controls the engine speed, while the safety features are designed to prevent accidents, such as an emergency stop mechanism or chain brake. Understanding these features is essential for safe operation and optimal handling of the tool.

How to Use the Parts Diagram for Repairs

When facing a malfunction or needing to replace a broken component, having a visual guide can be immensely helpful. A breakdown of the tool’s elements can serve as a reference, helping to identify specific parts that require attention. Understanding how to interpret these guides will not only speed up the repair process but also ensure that the correct components are addressed.

The first step is to locate the relevant guide for your tool. Once you have the visual layout, focus on identifying the components that need to be replaced or repaired. The layout typically shows each part labeled with its function and part number, making it easier to find the exact replacement needed. Pay attention to how parts are connected, as this helps in understanding the disassembly and reassembly process.

Additionally, using this guide allows you to spot common issues related to wear and tear. Once you’ve identified a problematic area, the guide can point you to the specific part that needs attention, whether it’s something simple like a cleaning or something that requires a replacement. With a clear understanding of the layout and function of each component, repairs can be performed with precision and ease.