Understanding the intricate structure of a chainsaw is crucial for effective maintenance and repair. A well-organized system of parts works together to ensure smooth operation, and knowing how each element contributes to performance is essential for any owner. This section delves into the detailed assembly of key components, providing insights for better upkeep.

Regular inspection and accurate identification of components are vital for troubleshooting and extending the lifespan of your tool. By breaking down the construction, it becomes easier to pinpoint issues and execute repairs with precision.

Whether you are a professional or a hobbyist, gaining knowledge about the machine’s internal workings empowers you to handle routine tasks and unexpected breakdowns effectively. This guide will walk you through the fundamental elements that make up a reliable and efficient chainsaw.

Understanding Chainsaw Components

Every chainsaw consists of a variety of interconnected elements that enable it to function efficiently. These individual components, though diverse in their design and function, all play a vital role in ensuring the tool runs smoothly and reliably. Understanding the relationships between these pieces helps in proper maintenance and troubleshooting, enhancing overall performance.

Core Components of a Chainsaw

The core structure of a chainsaw includes the engine, fuel system, cutting mechanism, and safety features. Each part is designed to work in harmony with the others, with the engine providing the necessary power, the cutting mechanism ensuring precision, and the safety features protecting the user during operation. Being familiar with each of these essential elements allows for better handling and care of the chainsaw.

Critical Maintenance Considerations

Routine checks and proper care of the major components, such as the air filter, fuel lines, and blade, are essential for keeping the tool in top condition. Neglecting any of these parts can lead to suboptimal performance or even failure. By regularly inspecting these components, one can prevent common issues and ensure a long-lasting, efficient machine.

Key Components for Maintenance and Repairs

To keep your tool in optimal condition, regular inspection and upkeep of its essential elements are necessary. Properly maintaining and replacing key components can prevent costly repairs and ensure smooth functionality over time. Knowing which parts require attention is vital for anyone looking to extend the lifespan of their equipment.

Engine and Fuel System

The engine and fuel system are fundamental to the operation of the tool. These parts need to be kept clean and free of debris to avoid performance issues. Replacing spark plugs, cleaning the air filter, and ensuring fuel lines are clear are important steps to maintain a reliable power source and smooth operation.

Cutting Mechanism and Safety Features

The cutting mechanism, including the blade and drive sprocket, must be regularly sharpened and checked for wear. Additionally, safety features such as the chain brake and throttle controls should be periodically inspected to ensure they function correctly. Keeping these elements in top shape will improve performance and protect the user from potential accidents.

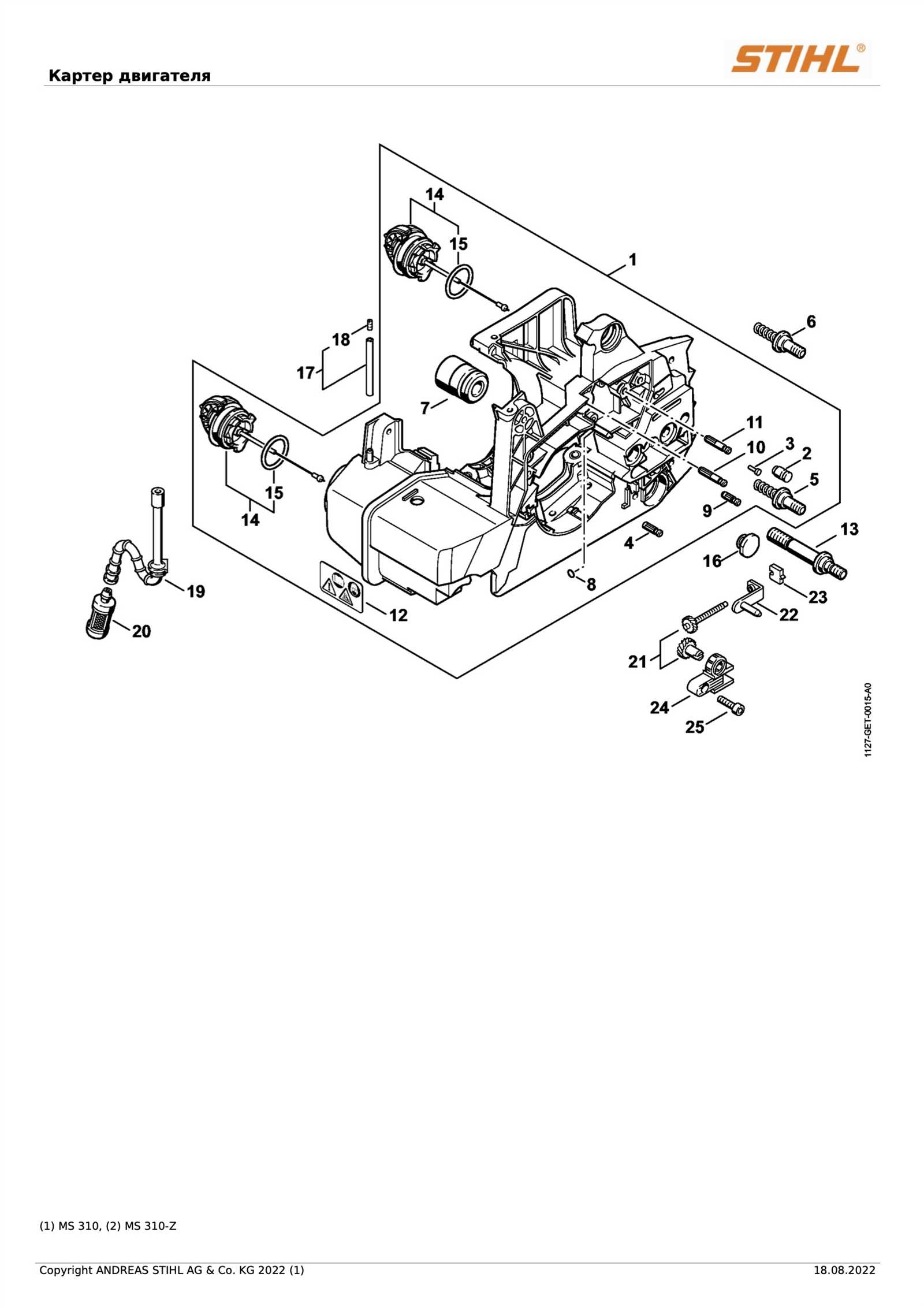

Step-by-Step Assembly Guide

Assembling the various components of your tool in the correct sequence is essential for ensuring proper functionality and safety. Each part must be carefully connected and securely fastened to avoid malfunctions during operation. Following a clear, organized process will make reassembly easier and help avoid unnecessary issues.

Preparing the Base Assembly

Start by positioning the main body on a flat surface. Install the engine and fuel system components first, ensuring all connections are tight and secure. Check that the intake and exhaust ports are properly aligned before proceeding to the next steps.

Attaching the Cutting Mechanism

Once the engine assembly is in place, attach the cutting mechanism. Begin with the drive sprocket, followed by the chain and blade. Ensure the components are securely attached, and verify that the chain tension is correct. Finally, install the safety features, such as the chain brake, and double-check that everything is functioning properly before testing.

How to Identify Each Component

Properly identifying each element within your tool is essential for maintenance, repairs, and troubleshooting. Understanding the function and appearance of each component allows for quicker diagnosis of issues and more efficient handling. Below are several key steps to help you recognize the important pieces of the assembly.

- Engine Assembly: This is typically the central part of the tool, often marked by a series of cooling fins and exhaust ports. It provides the necessary power to operate the tool.

- Fuel System: Look for components like the fuel tank, fuel lines, and the carburetor. These are essential for the proper intake and delivery of fuel to the engine.

- Cutting Mechanism: The cutting system usually includes the chain, bar, and drive sprocket. This assembly is designed to provide the cutting motion and should be checked for proper alignment and tension.

By following these guidelines, you’ll be able to quickly identify key components and ensure they are functioning properly for safe and effective use.

Common Issues with Tool Components

Over time, various elements of your equipment may experience wear and tear, leading to decreased performance or malfunction. Recognizing these common issues early can help prevent further damage and ensure smooth operation. Below are some typical problems that may arise with key components.

Engine Problems: The engine may struggle to start or run erratically if there is a buildup of dirt or debris in the air filter, carburetor, or spark plug. Regular cleaning and replacement of these components can help restore proper function.

Fuel System Issues: If the fuel lines become cracked or clogged, fuel delivery may be hindered, leading to poor performance. Inspecting and replacing worn fuel lines is necessary to keep the system running efficiently.

Cutting Mechanism Failures: A dull or improperly tensioned chain can cause the tool to cut inefficiently or even cause strain on the engine. Ensuring proper chain tension and regular sharpening will maintain optimal cutting performance.