Understanding the inner workings of your chainsaw is crucial for keeping it running smoothly. Whether you’re performing regular maintenance or fixing a specific issue, knowing the right components and how they fit together can save you time and effort. This guide aims to help you navigate the different elements that make up your tool and how to identify when they need attention.

Proper maintenance requires familiarity with the parts and how they function in unison. By studying the layout of each section, you can easily pinpoint potential problems, reduce downtime, and improve performance. This resource will break down the essential components, providing clear guidance for repairs and replacements.

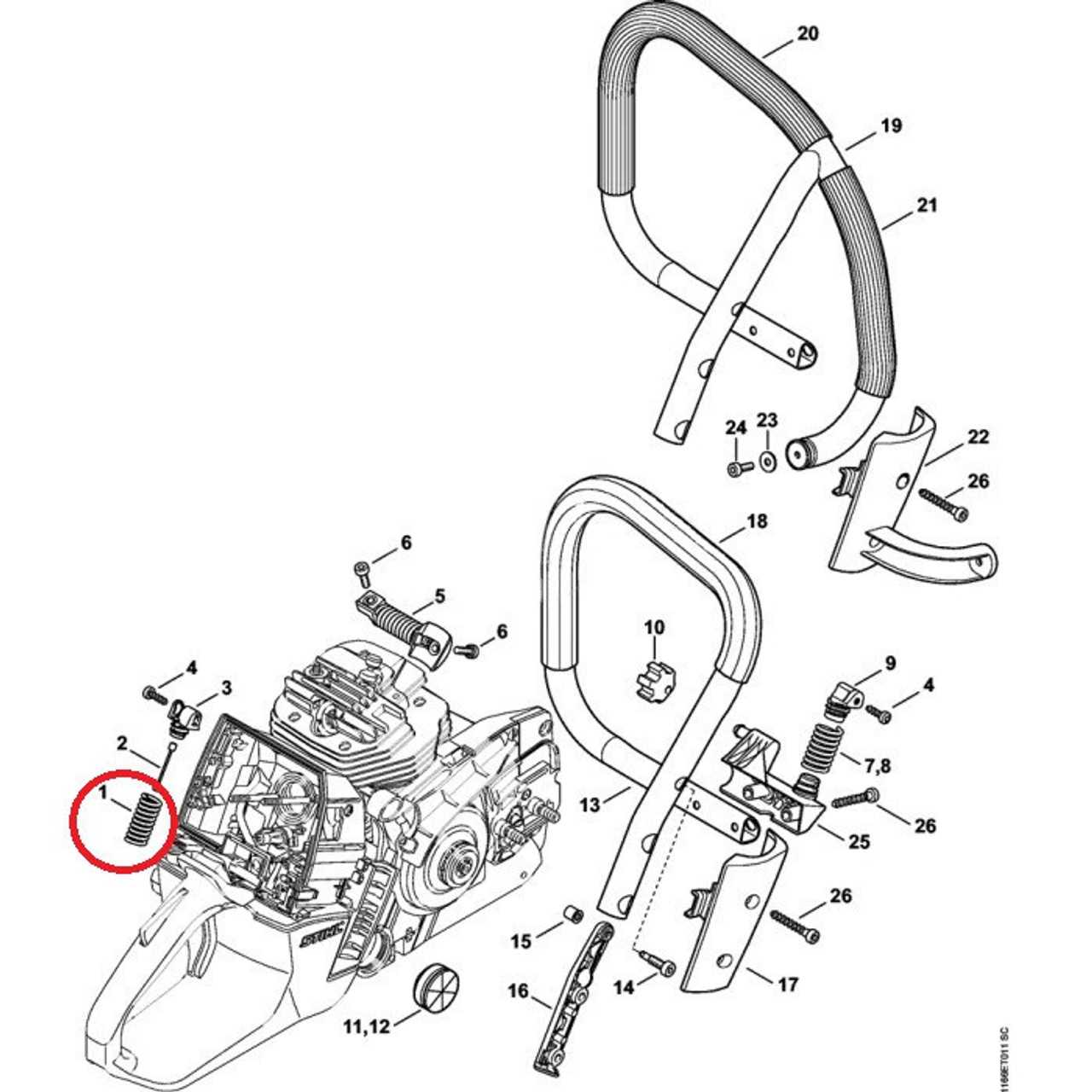

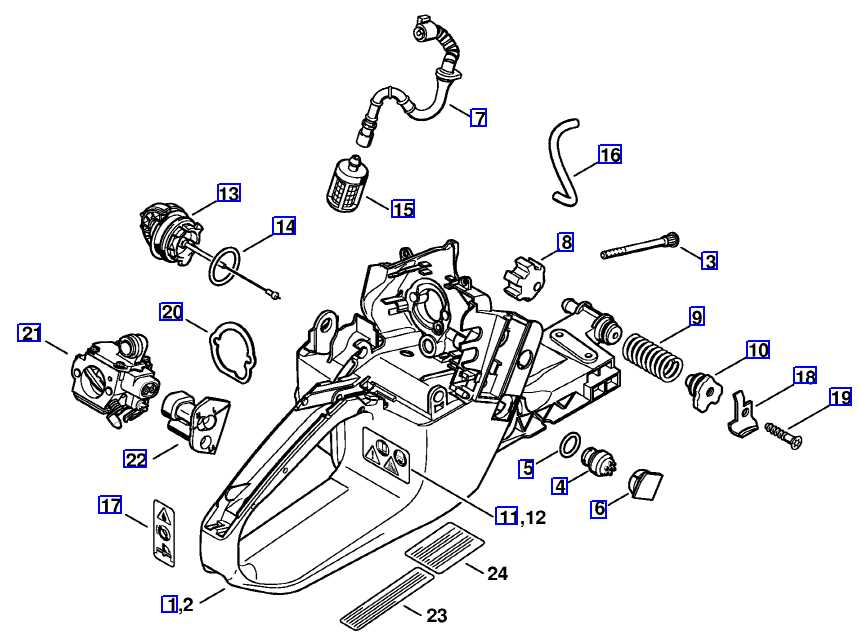

Learning how to interpret visual schematics is an invaluable skill for anyone who works with these machines. These illustrations serve as roadmaps, offering a clear view of all critical components, making repairs more manageable and efficient. With the right tools and knowledge, you can tackle any issue and restore your chainsaw to its optimal condition.

Understanding the Stihl MS311 Components

Every machine is made up of various critical elements that work together to ensure smooth operation. Recognizing these components and their roles is essential for efficient maintenance and troubleshooting. From the engine to the smaller, intricate mechanisms, each part serves a unique purpose, contributing to the overall performance and longevity of the tool.

The motor, air filtration system, and fuel delivery mechanism are some of the most vital elements, each directly affecting the machine’s power and efficiency. The ignition system, too, is a cornerstone, enabling the engine to start and run consistently. Other components like the bar and chain assembly, clutch, and lubrication system all play specific roles in making sure the tool functions properly during use.

Understanding the relationship between these parts allows for more accurate diagnostics. Whether you’re facing a power issue, experiencing inconsistent performance, or simply performing regular upkeep, knowing how each element contributes to the overall system is key. With this knowledge, you can take the necessary steps to maintain and repair the tool effectively, preventing more serious malfunctions down the line.

How to Use the Parts Diagram Effectively

Visual schematics are invaluable tools for understanding how different elements of a machine are connected and interact with each other. By referencing these detailed illustrations, you can quickly identify the location of components and better understand their functions. This can simplify the process of assembly, disassembly, and repair, ensuring you approach maintenance tasks with precision and confidence.

To use these illustrations effectively, start by familiarizing yourself with the overall layout and the key sections of the machine. Pay close attention to the numbers or labels attached to each component, which will help you match them with their corresponding parts when ordering replacements or performing repairs. It’s also important to understand the flow of systems, such as how the engine, fuel delivery, and exhaust components work together.

When troubleshooting, these diagrams become especially useful. They allow you to cross-check symptoms with specific parts, helping you identify worn or faulty components that may be causing the issue. By consulting the visuals and understanding the location of each part, you can focus your efforts on the exact area in need of attention, avoiding unnecessary steps and saving time on repairs.

Common Issues and Replacement Parts for MS311

Like any mechanical tool, chainsaws can encounter a variety of issues during their lifespan. Understanding the common problems that arise and knowing the specific components that need to be replaced can help maintain the tool’s performance and prevent unexpected breakdowns. Regular inspection and timely replacement of worn parts are essential to keep the equipment running efficiently.

One of the most frequent issues is a lack of power, which can stem from problems with the ignition system or fuel delivery. A faulty spark plug or a clogged carburetor can hinder engine performance. Similarly, the chain may wear out over time or become loose, causing inefficient cutting. Replacing the chain and ensuring proper tension can resolve these issues and restore cutting power.

Other components such as the air filter and the oil pump can also become clogged or damaged, leading to overheating or poor lubrication. These are simple to replace and can prevent more serious engine damage. Regular maintenance and using quality replacement components will help ensure that the machine stays in optimal condition, avoiding costly repairs and ensuring longevity.