Understanding the internal structure of a chainsaw is essential for anyone performing maintenance or repairs. This guide provides a clear overview of how each part interacts to ensure smooth operation. Proper knowledge of the different sections and components can significantly enhance the longevity and efficiency of your machine.

Each tool consists of various elements, from the engine to the cutting system. By exploring these components, users can identify potential issues more easily and take the necessary steps to resolve them. Accurate identification of each element plays a key role in troubleshooting and ensuring the safety of the equipment during use.

Whether you are a seasoned professional or a beginner, familiarizing yourself with the mechanics of the chainsaw will help in performing quick repairs and improving overall performance. Understanding its intricate layout can lead to more efficient maintenance, saving both time and money.

Understanding Chainsaw Components

Every cutting machine is built with various essential elements that work together to achieve optimal performance. Familiarizing yourself with these components is crucial for effective operation, repair, and maintenance. By understanding the layout and function of each part, you can improve the overall reliability of your tool and address issues more efficiently.

Key Components for Efficient Operation

At the heart of the machine is the engine, which powers the entire system. Alongside it are critical components like the air filtration system, fuel system, and ignition components. These elements are vital for ensuring smooth and uninterrupted operation. The cutting mechanism, including the chain and guide bar, are designed to provide precision and efficiency during use. Each component must work in harmony to ensure reliable performance, making regular inspection and care necessary.

Maintenance and Repair Considerations

Proper maintenance involves knowing how to handle and replace specific parts as needed. Regular checks on elements like the carburetor, clutch, and spark plug are essential for preventing wear and tear. In-depth knowledge of how each component functions allows users to identify early signs of damage and make informed decisions on repairs. Staying proactive with upkeep not only extends the life of the tool but also guarantees its efficiency during every use.

How to Read the Assembly Layout

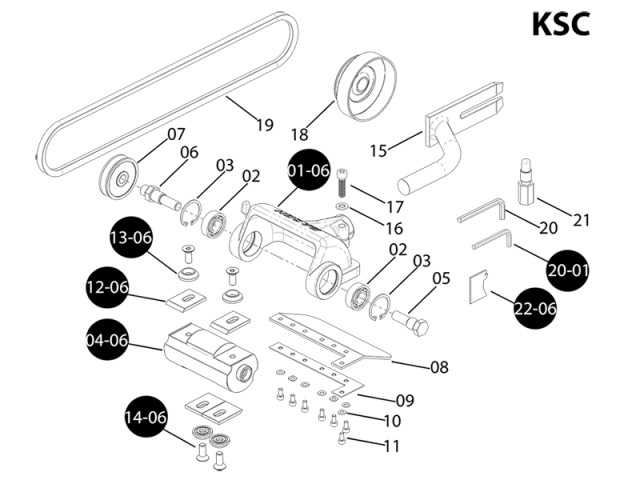

Understanding how to interpret a visual breakdown of a machine’s components is key for anyone looking to perform repairs or maintenance. These illustrations provide a detailed view of how each part is connected, helping you identify their functions and placements. By studying the layout, users can quickly pinpoint any issues and understand how the system operates.

Identifying Components in the Layout

The first step in reading a component illustration is recognizing the different sections and their labels. Each part is usually marked with a number or name, allowing you to cross-reference it with a list that describes its specific function. Understanding the numbering system is crucial, as it enables you to follow the assembly step by step. This clarity helps avoid confusion when it’s time to make repairs or replacements.

Interpreting the Connections

The next step is understanding how each part is connected. The lines and arrows in the layout represent the relationships between various components, showing how they interact. Pay close attention to these connections to ensure that when you’re performing maintenance, you know how to disassemble and reassemble the system correctly. Knowing the layout helps in preventing errors during reassembly and guarantees that the machine functions as intended.

Common Components and Their Functions

Every cutting tool relies on specific components that work together to ensure smooth and efficient operation. Understanding the functions of each essential element is vital for proper maintenance and troubleshooting. By learning about the most common parts, you can effectively manage repairs and optimize the tool’s performance.

Engine and Power System

The engine is the core of the machine, providing the power needed for all functions. It is supported by the fuel and air systems that ensure proper combustion. Components such as the carburetor, spark plug, and fuel filter play crucial roles in maintaining fuel efficiency and starting reliability. Regular inspection of these parts ensures that the engine runs smoothly and consistently without interruption.

Cutting Mechanism

The cutting mechanism includes the guide bar and chain, which work in tandem to provide precision during operation. The guide bar provides a stable path for the chain, while the chain’s teeth engage the material being cut. Regular maintenance of these components is essential for maintaining cutting performance. Ensuring the chain is properly tensioned and sharpened prevents unnecessary wear and increases cutting efficiency.