When it comes to maintaining and repairing your chainsaw, having access to a detailed reference document is crucial. A well-organized visual guide can help you identify each individual element, ensuring that repairs are made accurately and efficiently. Understanding the layout and configuration of components is the key to successful upkeep and troubleshooting.

For enthusiasts and professionals alike, accessing a clear schematic of the equipment’s inner workings can greatly simplify the process of diagnosing issues. This resource allows for easy identification of each part and its function, making assembly and disassembly more straightforward.

With the right reference, you can confidently handle any maintenance task. Whether you need to replace a specific component or just want to understand the overall structure of the tool, having the right guide in hand will make all the difference in your repair experience.

Understanding the Chainsaw Component Layout

Having a clear visual representation of your tool’s internal structure is essential for effective maintenance and repair. A detailed reference guide provides a map of how the various elements are organized and interact. This allows users to quickly pinpoint where issues may arise and how to resolve them. By familiarizing yourself with the layout, you can approach repairs with confidence and accuracy.

How to Read the Reference Guide

The reference document typically breaks down the machinery into labeled sections, each representing a different functional area. Understanding these labels and how they correlate with the tool’s operation will help you identify specific components. Focus on the parts that are most commonly replaced or adjusted during routine maintenance. This approach will save time and effort when you need to perform repairs.

Advantages of Using the Layout for Maintenance

By using a detailed schematic, you gain insight into the connections between different components, making the repair process more intuitive. Whether you’re fixing a malfunction or performing routine upkeep, understanding how the tool is constructed is essential. This knowledge ensures that parts are installed correctly, reducing the risk of errors and ensuring a longer lifespan for your equipment.

How to Use the Reference for Repairs

When it comes to repairing your equipment, having a visual guide can be extremely helpful. A well-organized reference allows you to understand the structure of your tool and easily identify the components that need attention. Using this guide properly will make repairs more efficient and reduce the likelihood of errors.

Steps for Repairing with the Visual Guide

Follow these steps to ensure a smooth repair process:

- Locate the Issue: Start by identifying the problem area. Check the operational symptoms to narrow down where the issue may lie.

- Find the Relevant Section: Use the reference to find the area related to the malfunction. The guide will have clear sections that are labeled according to function or part type.

- Verify Components: Cross-reference each part in the area to ensure that it is intact and functioning properly.

- Gather Replacement Parts: Based on the guide, locate the specific parts you need to replace. This will ensure that you’re using the correct components for your repair.

- Perform the Repair: Using the guide, carefully remove the damaged components and replace them with new ones as indicated.

Benefits of Using the Reference for Repairs

- Accuracy: A visual guide ensures that each step is followed precisely, reducing the risk of mistakes.

- Time-saving: Instead of guessing or trial-and-error, having a clear roadmap makes the process much quicker.

- Prevents Further Damage: By following the guide, you avoid causing additional issues that could arise from improper repairs.

Parts Identification for Your Chainsaw

Accurate identification of components is a crucial step in the repair and maintenance process. By understanding the function and location of each element in your equipment, you can quickly address issues and ensure efficient operation. A detailed reference can help you pinpoint specific pieces, making it easier to troubleshoot and replace damaged or worn-out parts.

Each part plays a distinct role in the overall functioning of the tool, and recognizing their position and connection within the system is vital. Familiarizing yourself with these components allows for quicker assessments and smoother repairs. With the right guide, even complex machinery becomes more approachable, reducing uncertainty during maintenance.

Key Components and Their Functions

Understanding the critical components of your equipment is essential for effective maintenance and repair. Each part serves a unique purpose and works in harmony with others to ensure smooth operation. Knowing the function of each element helps in diagnosing issues and making precise adjustments or replacements when necessary.

The following table outlines some of the key components and their primary functions within the machinery:

| Component | Function |

|---|---|

| Engine | Drives the mechanical parts, providing the necessary power for operation. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion, ensuring optimal engine performance. |

| Chain Brake | Stops the chain in case of sudden movement or kickback, improving safety. |

| Clutch | Transfers power from the engine to the chain, allowing it to rotate and perform tasks. |

| Fuel Tank | Holds the fuel required for the engine, ensuring it has enough to operate for extended periods. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean air for combustion. |

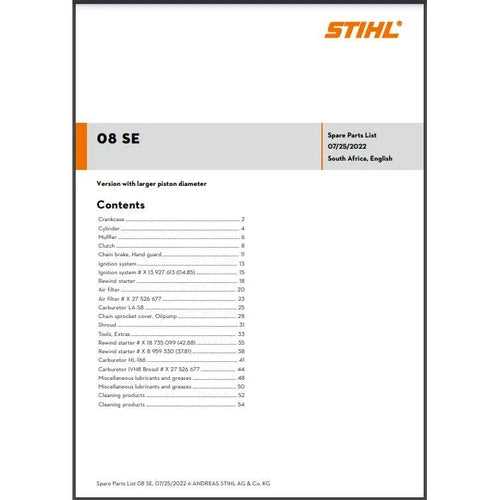

Accessing and Downloading the Reference Guide

To perform accurate repairs and maintenance, having access to a detailed schematic is essential. These resources are often available online for easy download, providing a clear view of the internal structure and components of your equipment. Accessing and downloading this reference guide ensures that you have the necessary information at your fingertips when performing any service tasks.

Here are the steps to easily access and download the reference guide:

- Search for the Guide: Use the model name and the term “manual” or “service guide” in your search to locate the official document.

- Select the Correct File: Be sure to download the most up-to-date version to ensure accuracy and completeness.

- Download the File: Click on the provided download link, and choose the location on your device where you’d like to save the file.

- Open and View: Once downloaded, open the file with a compatible viewer to begin exploring the components and their functions.

Having the guide in a downloadable format allows you to refer to it anytime, whether you’re in the workshop or on the go. This convenience enhances your ability to perform repairs with precision and confidence.