Every tool, regardless of its type, consists of numerous elements that work together to ensure optimal performance. Knowing how to identify and manage these components is key to extending the tool’s lifespan and functionality. Proper understanding of the structure allows for better maintenance and simpler repairs, saving both time and money.

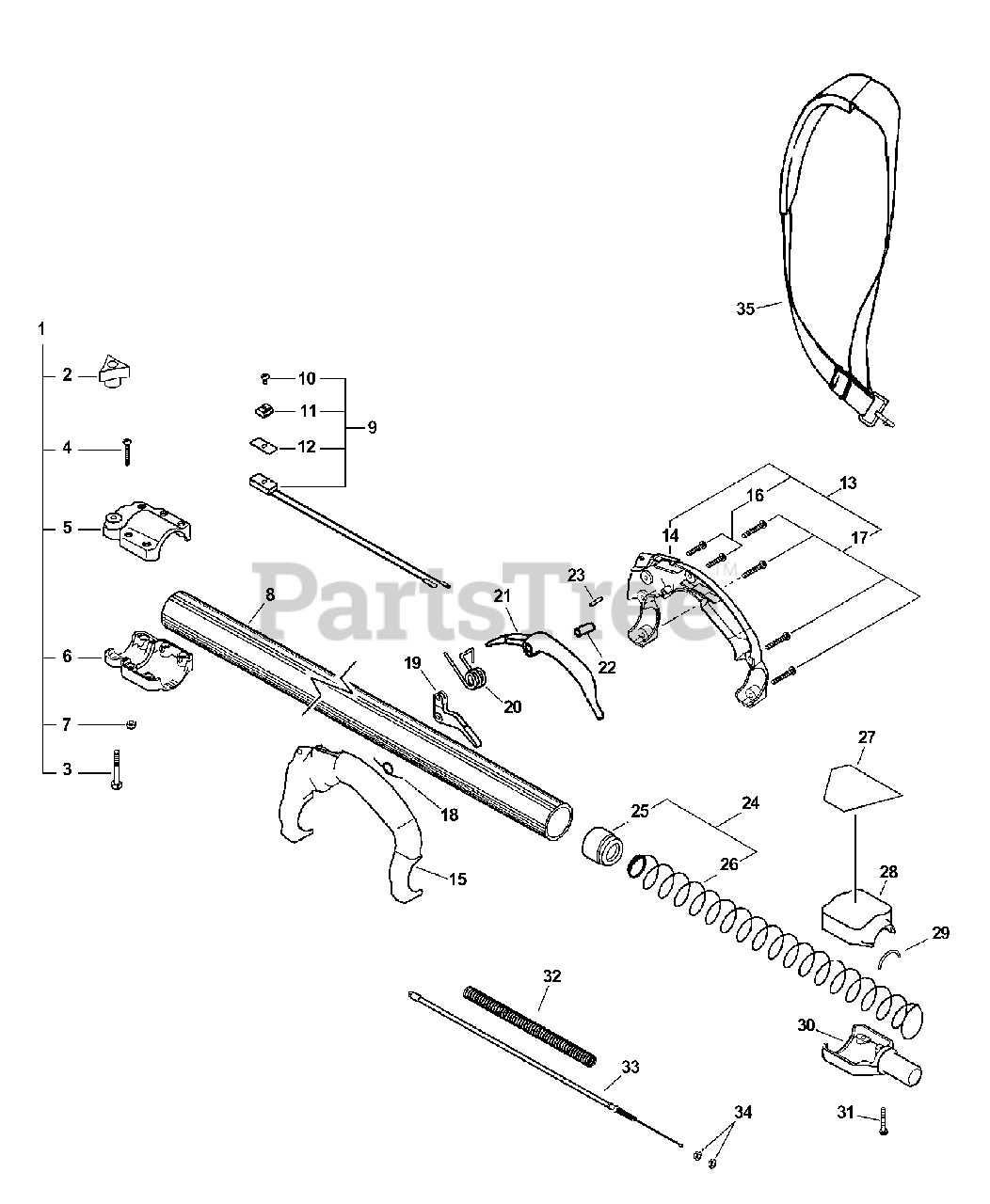

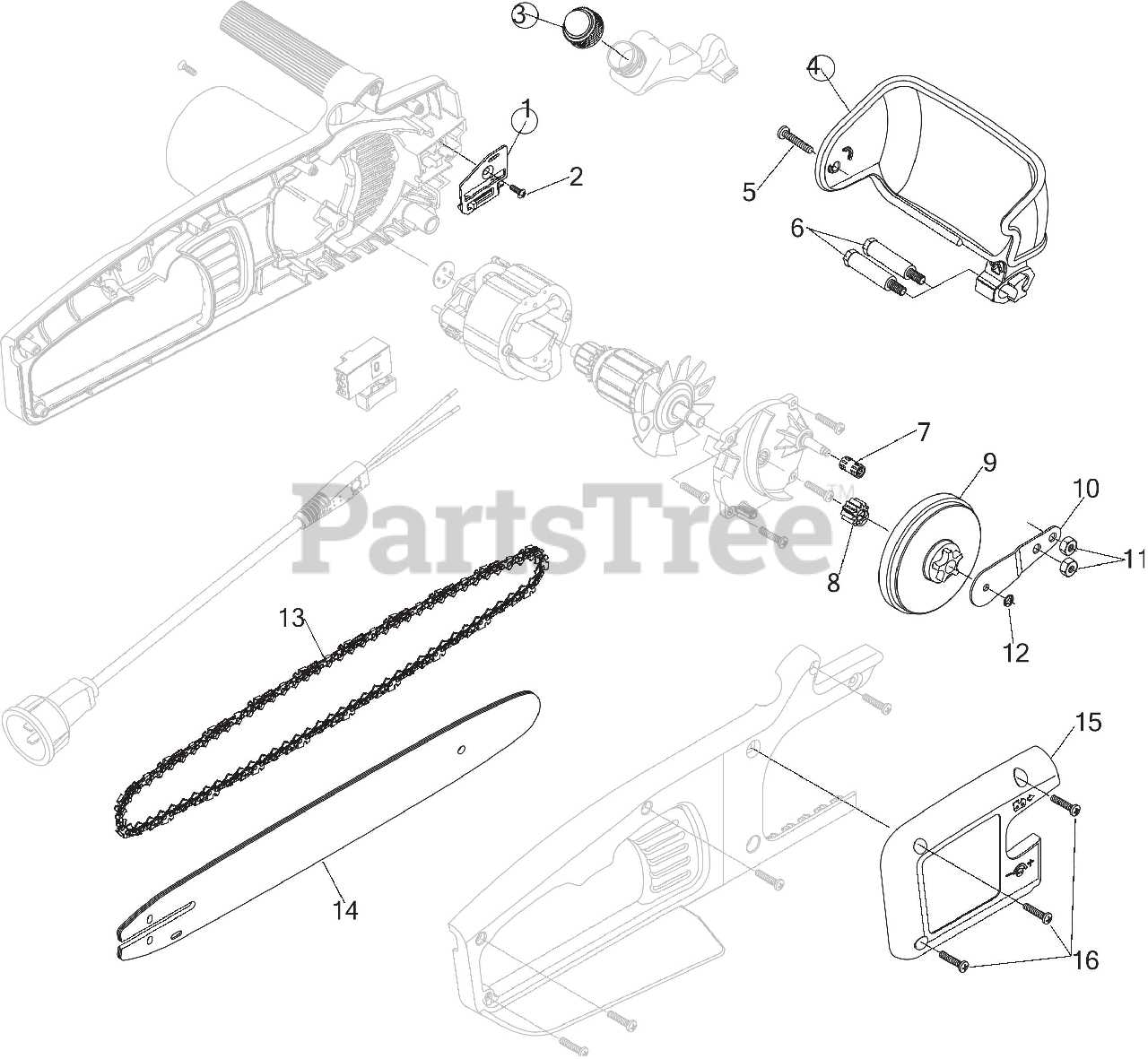

When dealing with a complex tool, having a clear visual representation of its individual sections can be immensely helpful. It helps users identify any worn-out or broken components and allows them to replace parts accurately. This understanding ensures smooth operation, preventing unnecessary issues during use.

Whether you are an experienced technician or a DIY enthusiast, knowing how to interpret the structure of your tool is essential for efficient repairs. It aids in simplifying the maintenance process and ensures that every part functions as intended, reducing the risk of malfunction or damage over time.

Understanding Stihl Pole Saw Parts

Every tool is built with a combination of critical components, each serving a specific function that contributes to its overall performance. Understanding how each piece works together can help ensure smooth operation and longevity. When it comes to managing a tool, knowledge of these elements is essential for troubleshooting and repair.

The structure of such equipment includes both visible and internal elements, each playing an important role in its mechanics. Identifying these sections allows users to quickly pinpoint any problems, whether they are related to wear, damage, or misalignment. This understanding helps in maintaining efficiency and ensures that all components are working harmoniously.

Familiarizing yourself with the various elements of your tool is important for both routine maintenance and emergency repairs. Knowing which parts are prone to wear or are difficult to replace can help in preparing for necessary actions when problems arise. It can also improve the performance of the tool by enabling accurate repairs and replacements when needed.

How to Read a Stihl Pole Saw Diagram

Understanding how to interpret an assembly guide is crucial when working with complex equipment. These visual representations offer a clear overview of the different components and their relationships, making it easier to locate and identify specific sections. Whether for repair or maintenance, knowing how to read these visuals will streamline the process and reduce confusion.

Identify the Key Components

The first step in reading an assembly guide is to familiarize yourself with the key elements. Most guides include labels or numbering systems that correspond to different sections of the tool. Recognizing these parts helps in understanding their function and determining which ones require attention.

Understand the Assembly and Disassembly Process

After identifying the key components, it’s important to understand how they fit together. Diagrams typically show how each part connects and aligns with others. Knowing the assembly process allows you to follow the correct order when disassembling or reassembling the tool, ensuring a smooth and efficient process.

Essential Components for Pole Saw Repair

When performing maintenance or repair on any tool, it’s crucial to identify the essential components that play a significant role in its function. Each section must be thoroughly checked to ensure proper performance. Recognizing which components are most likely to wear out or become damaged will help prevent future issues and ensure smooth operation.

Motor and Drive Mechanism

The motor and drive mechanism are at the heart of the tool’s functionality. Ensuring these components are in good condition is essential for proper power transmission. A malfunctioning motor or drive mechanism can lead to poor performance or even complete failure, making it important to inspect these parts regularly.

Cutting Mechanism and Blade Assembly

The cutting mechanism is responsible for executing the primary task of the tool, so maintaining it is vital. The blade assembly should be regularly sharpened and checked for wear or damage. Faulty or dull blades can affect cutting efficiency, leading to longer working hours and more stress on the machine.