Understanding the structure of your machinery is essential for efficient maintenance and repairs. Having a clear visual representation of the various elements and their connections can significantly simplify the process of troubleshooting and part replacement. This guide will help you navigate the assembly and identify the right components when the time comes for maintenance.

Whether you are a professional or a DIY enthusiast, knowing where each part fits and how it interacts with the others is crucial. With this visual reference, you can confidently manage repairs, ensuring your equipment stays in optimal condition for longer periods. Regular maintenance backed by an accurate guide can prevent costly breakdowns and improve the lifespan of your tools.

In this article, we will break down key mechanical systems, highlight essential components, and show you how to use these resources to keep your machine running smoothly. By the end, you’ll be equipped with the knowledge needed to tackle any repair task with confidence.

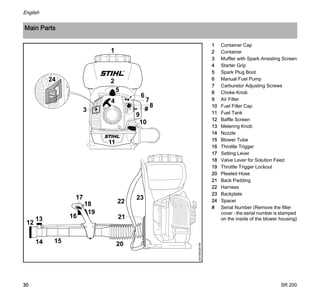

Understanding the Equipment Layout

Familiarizing yourself with the layout of your machinery is a crucial step toward efficient repairs and maintenance. A detailed breakdown of the system’s components and their interconnections allows for easier identification of potential issues and the appropriate replacement parts when necessary. The clearer the layout, the simpler the process of addressing any mechanical problems.

Each element of the machine plays a specific role in its overall performance. By understanding how these individual pieces fit together, you can better assess the condition of your equipment and make informed decisions about repairs. This knowledge is especially valuable when troubleshooting, as it helps pinpoint the source of malfunction quickly and accurately.

In this section, we will focus on key systems and their components, showing how they integrate to function efficiently. With a well-structured visual reference, maintenance becomes a more manageable task, ensuring that your equipment remains reliable and performs at its best.

Key Components of the Engine

Understanding the core elements that power your machine is essential for proper upkeep. Each key component plays a vital role in ensuring smooth operation and preventing mechanical failures. By recognizing how these parts function individually and together, you can effectively diagnose issues and perform necessary maintenance.

The engine’s primary components, such as the ignition system, fuel delivery system, and exhaust, are interconnected to optimize performance. The ignition system, for example, ensures that the engine starts reliably, while the fuel system controls the delivery of fuel for efficient combustion. Regular inspection and servicing of these parts can greatly extend the life of your equipment and maintain its efficiency.

In this section, we will highlight the most critical parts that form the engine assembly, providing insights on their functions and the best practices for keeping them in top condition. Familiarity with these components helps reduce downtime and ensures your machinery operates at peak performance.

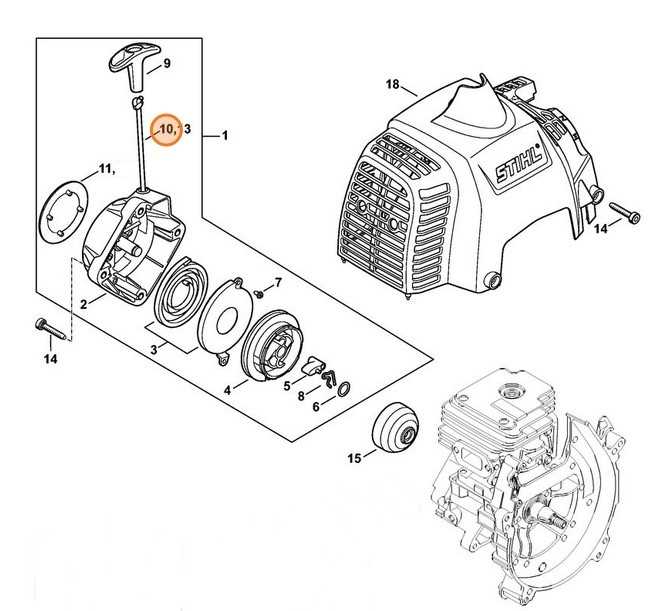

How to Use the Visual Guide for Repairs

Using a visual reference for repair tasks can significantly improve the efficiency and accuracy of maintenance work. It allows you to quickly locate damaged or worn-out components and identify the correct replacements. This process can save time and prevent errors that may occur when working with complex machinery.

Here’s how to effectively use this guide for your repair needs:

- Identify the Problem Area: Start by locating the malfunctioning component. Carefully examine the machine to determine which part is causing issues.

- Match Components: Refer to the visual reference and match the part you need to replace with the corresponding image or label. This will help ensure you choose the right component for the repair.

- Remove the Damaged Part: Once identified, carefully disassemble the machine to remove the faulty part. Use proper tools and follow the guidelines for safe removal.

- Install the Replacement: After selecting the correct replacement, install it by following the assembly instructions. Make sure it fits securely and functions correctly within the system.

- Test the Equipment: After the replacement, test the machine to ensure the repair has been successful and everything is working smoothly.

By following these steps and utilizing the visual guide, you can streamline the repair process and ensure that your equipment is back in working condition in no time.