Maintaining and repairing outdoor tools can often seem like a daunting task, especially when it comes to identifying and replacing specific components. Whether you’re a seasoned professional or a weekend enthusiast, knowing how to recognize and handle the various elements of your equipment is crucial for keeping it in optimal working condition.

Clear and detailed illustrations can simplify this process, offering a visual reference for understanding how each part fits together and functions. By having access to a well-organized layout, you can easily pinpoint worn or damaged pieces, making repairs more straightforward and less time-consuming.

Recognizing common issues and understanding the components involved allows you to make informed decisions when it comes to replacements or upgrades. Knowing the specific role of each element can ultimately lead to more efficient maintenance and prolonged tool life.

Understanding Key Outdoor Equipment Components

Every outdoor tool consists of multiple elements that work together to perform specific functions. A solid understanding of these components is essential for troubleshooting, maintenance, and repairs. Whether you’re dealing with a machine that cuts, trims, or weeds, knowing how each part contributes to the overall performance helps ensure the equipment runs smoothly and efficiently.

Main Functional Parts

The core components of any equipment include the power source, cutting mechanism, and control system. The power source drives the tool, while the cutting mechanism handles the task at hand, whether it’s slicing through grass or clearing tough vegetation. The control system, often consisting of handles and buttons, enables you to adjust speed, direction, or power as needed. Understanding the interaction between these elements is key to diagnosing issues and maintaining performance.

Wear and Tear: Commonly Affected Components

Over time, certain parts of the equipment are more prone to wear. The cutting elements, such as blades or strings, can become dull or damaged, affecting efficiency. Other components like the motor, fuel lines, and air filters also require attention to prevent performance issues. Regular inspection of these parts ensures early identification of problems and allows for timely replacements, which can extend the lifespan of the machine.

How to Read a Tool Component Illustration

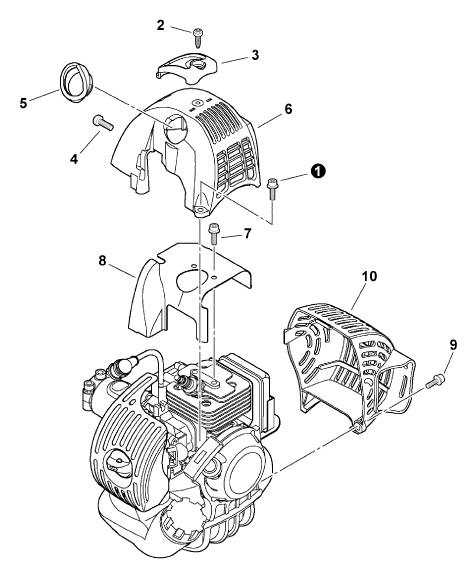

Understanding technical illustrations can significantly ease the process of identifying components and performing repairs. These visual references often provide a clear layout of how different elements of the tool are arranged and interact with one another. By learning how to interpret these illustrations, you can quickly locate specific parts and understand their function within the system.

Interpreting Symbols and Labels

Most component illustrations feature specific symbols and labels that help identify each part. These could include part numbers, names, and additional notes regarding material or dimensions. Pay close attention to these markings, as they provide essential information for ordering replacements or understanding how each component fits into the assembly.

Understanding Part Placement and Connections

In addition to labeling, these visuals show the arrangement of parts within the tool, highlighting how each element connects or fits into the overall structure. Arrows and lines often indicate how parts align or how certain components move in relation to others. This understanding allows for more precise disassembly, reassembly, and maintenance tasks, ultimately ensuring your tool functions optimally.

Common Issues and Replacement Parts

Like any tool, outdoor equipment can face performance issues due to wear and tear over time. Recognizing the most common problems and knowing which components need replacing is crucial for maintaining the efficiency and longevity of your machine. Regularly inspecting these key areas allows you to address issues early and keep your equipment running smoothly.

Frequent Problems in Outdoor Equipment

One of the most common issues is reduced cutting performance, often caused by dull or damaged cutting elements. Whether it’s a blade or a line, these components can wear out quickly with prolonged use. Another frequent problem is engine malfunction, which may result from clogged filters, dirty spark plugs, or fuel line blockages. Regular maintenance can help prevent these issues from disrupting operation.

Essential Replacement Components

When problems arise, certain components are more likely to need replacing. For instance, cutting elements such as blades, strings, or cords often require regular replacement to maintain optimal cutting performance. Other commonly replaced parts include air filters, spark plugs, and fuel lines. Keeping spare parts on hand can minimize downtime and ensure your equipment is ready when needed.