When working with heavy-duty equipment, understanding its internal structure is essential for effective maintenance. Knowing the individual components and how they fit together ensures a smooth repair process and extends the lifespan of your machine.

In this guide, we will walk you through the essential elements of your tool, explaining the various components and their functions. Having a clear understanding of these parts can help you diagnose issues and perform timely repairs, avoiding unnecessary downtime.

Whether you are an experienced user or new to machinery, this resource will provide valuable insights into how to manage your equipment efficiently. Proper knowledge of assembly and disassembly is crucial for maintaining performance and safety over time.

Understanding Key Equipment Components

When it comes to operating a powerful tool, each component plays a critical role in its overall functionality. Familiarizing yourself with these elements allows for better troubleshooting and efficient repairs. Recognizing how each piece interacts helps ensure your machine runs smoothly and effectively.

Core Functional Elements

The engine and cutting mechanisms are the heart of any machinery. Understanding how these elements are interconnected is essential for optimal performance. The power source drives the cutting action, while other parts manage the tool’s stability and precision. A detailed knowledge of these components can prevent unnecessary wear and damage, improving both safety and efficiency.

Maintenance and Replacement Considerations

Routine maintenance involves inspecting and replacing worn-out components to keep the tool performing at its best. Knowing which parts are most prone to wear, such as belts or filters, ensures you stay proactive in maintaining your equipment. Regular checks for damage or misalignment can help avoid costly repairs and prolong the life of your tool.

How to Read the Equipment Layout

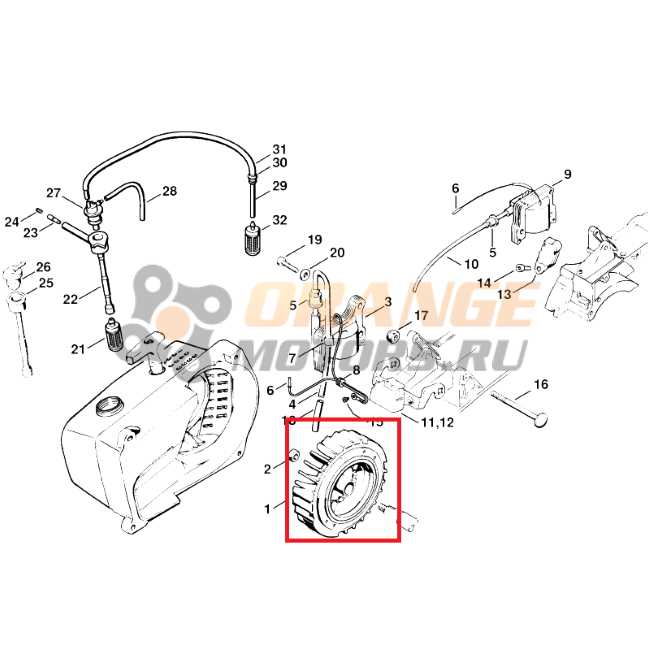

Understanding the visual representation of your machine’s components is crucial for proper maintenance and repairs. A well-structured layout helps identify each part and its location, making it easier to troubleshoot and replace components when necessary. Knowing how to interpret these illustrations ensures accurate repairs and reduces the risk of errors.

Each section of the visual guide corresponds to a different area of the machine, often divided by function or accessibility. The components are typically numbered or labeled, which corresponds to the descriptions or part numbers listed in the accompanying manual. This system simplifies the identification of each element, allowing for efficient assembly and disassembly.

Pay attention to the symbols and lines connecting various components, as they often indicate how pieces interact or are connected. Understanding these relationships will help you address issues quickly and accurately, improving the overall maintenance process.

Common Issues and Replacement Components

Every piece of equipment faces common challenges over time, whether from wear, environmental conditions, or heavy usage. Understanding these frequent issues and knowing the right replacement components can help maintain the tool’s performance and extend its service life. Proactive attention to these problems prevents costly downtime and keeps your machine operating efficiently.

One of the most common issues is the wear of moving parts, such as belts, filters, and spark plugs. These components often require regular replacement to avoid malfunctions. Clogs or dirt buildup can also affect performance, requiring cleaning or the replacement of filters to maintain airflow and power efficiency.

Another common problem is misalignment or damage to cutting mechanisms, which can cause reduced efficiency or safety risks. Identifying the damaged parts and replacing them quickly helps prevent further damage to other components. Regular inspections and timely replacements are key to avoiding significant repairs down the line.