When working with any mechanical tool, understanding its internal components is crucial for efficient maintenance and troubleshooting. Knowing where each part fits and how they interact ensures smoother operation and longer service life. This is especially important for anyone who relies on their equipment for heavy-duty tasks.

In this section, we will provide a comprehensive overview of the key elements of a popular chainsaw model. By familiarizing yourself with the layout, you can better identify any issues and know exactly which parts may need attention or replacement. Understanding the structure of your tool also aids in performing repairs and assembling new components.

Whether you’re a professional or a hobbyist, gaining insight into the tool’s construction will help you make informed decisions when it comes to repairs and upgrades. Knowing how to handle each part properly ensures that your chainsaw functions at its best, delivering top-notch performance with every use.

Understanding Chainsaw Components Layout

Every mechanical tool, especially those used for heavy-duty tasks, is made up of several interconnected components that work together to ensure smooth operation. Understanding how these elements are arranged and how they function within the system is essential for proper maintenance and troubleshooting. A clear understanding of the tool’s construction allows for quicker diagnostics when problems arise.

The arrangement of these components is crucial for both the functionality and the longevity of the equipment. Each part plays a vital role in the overall operation, from the engine to the cutting mechanism. Knowing how to recognize each element and its position can help you identify any potential wear or damage, ensuring you can perform necessary repairs promptly.

In this section, we will break down the essential components of a common model, exploring how each piece contributes to the tool’s efficiency. By gaining a better understanding of the layout, you will be able to identify which components are more susceptible to damage and how to replace them when needed.

How to Read the Chainsaw Layout

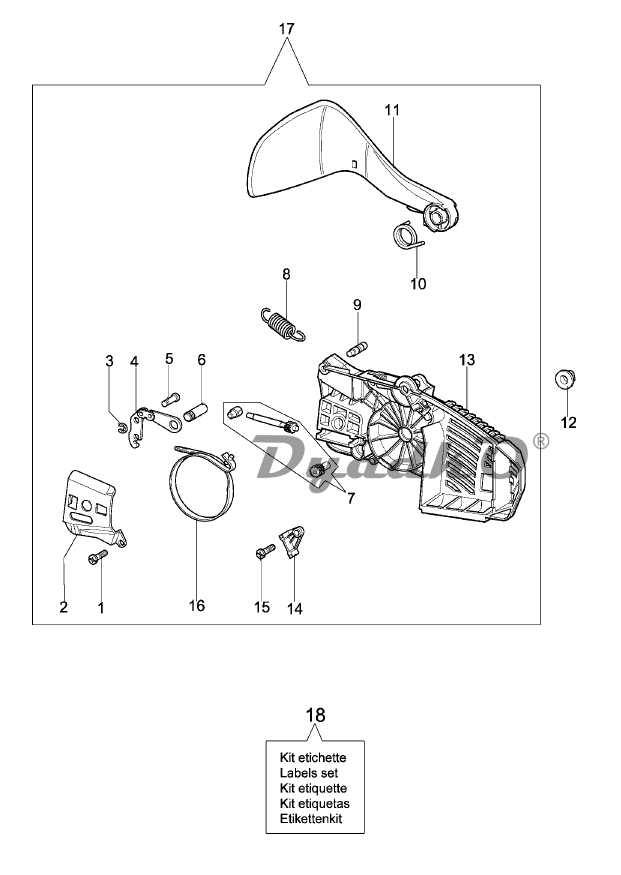

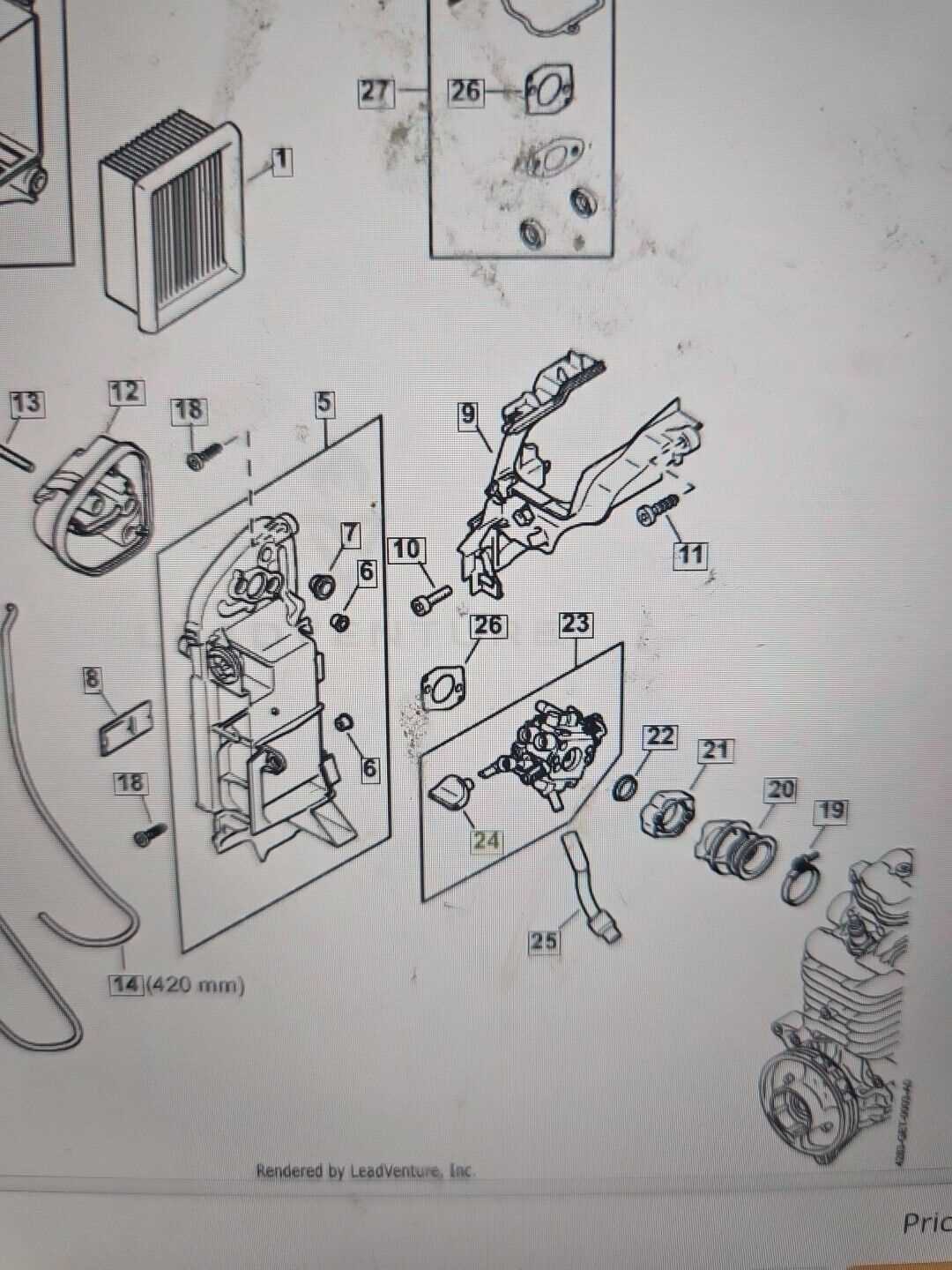

Understanding how to read an equipment layout is a key skill for anyone maintaining or repairing mechanical tools. These visual representations provide a clear, organized view of all the crucial components, allowing you to easily identify each part and its specific location. By learning to interpret these layouts, you can make the repair process more efficient and reduce the risk of mistakes.

The layout typically includes labeled components, with each section offering insight into how parts are connected and interact. It is essential to familiarize yourself with the symbols and numbering conventions used to describe these elements. These visual guides are designed to help you pinpoint exactly which components are at fault or require replacement, saving you time during repairs.

Once you are familiar with the layout, it becomes much easier to navigate through complex repair procedures. With a clear understanding of where each component belongs, you can also ensure that everything is reassembled properly. Knowing how to read this guide thoroughly can prevent unnecessary confusion and help you maintain the tool in optimal working condition.

Common Issues and Spare Parts for Chainsaw

Mechanical tools, especially those used for demanding tasks, often experience wear and tear over time. Recognizing the most common issues can help you address them before they cause major disruptions to the tool’s operation. Identifying which parts are most prone to damage allows you to keep the tool functioning properly and avoid unnecessary downtime.

Among the frequent issues that arise with this type of equipment are problems with the ignition system, fuel delivery, and the cutting mechanism. These areas are crucial for the tool’s performance, and any malfunction can significantly affect its efficiency. Knowing the common signs of wear and the parts involved can help in troubleshooting and repairs.

Having access to the right spare components is essential for quick fixes. Parts such as air filters, spark plugs, fuel lines, and chains are some of the most commonly replaced items. Understanding which spare parts you might need in advance ensures that you can address problems promptly, minimizing interruptions and extending the life of your equipment.