Understanding the intricate layout and structure of your vehicle is essential for proper maintenance and repair. Whether you’re a seasoned mechanic or a DIY enthusiast, knowing how each element fits together can save time and money. This guide will help you navigate through the detailed structure of your truck, making it easier to identify, replace, or upgrade specific components when necessary.

By using a comprehensive reference that illustrates the various sections and components of your vehicle, you can streamline repairs and ensure that no detail is overlooked. From the engine to the suspension system, this visual reference will provide clarity, reducing the risk of mistakes and enhancing your overall repair process.

With the right knowledge and tools, tackling complex repairs becomes more manageable, and you can maintain your vehicle in top condition for years to come. This guide will serve as a helpful resource, offering clear visual aids to support your understanding and repair efforts.

Understanding the Vehicle Components

Every vehicle is composed of a complex system of interconnected elements that work together to ensure smooth operation. To maintain or repair any truck, it’s essential to understand the various sections and how they function. A solid understanding of the structure helps identify problems quickly, reducing downtime and improving efficiency during maintenance tasks.

When working on a specific model, each unit may have unique features or configurations. Familiarizing yourself with the arrangement of components, from the engine to the transmission, suspension, and electrical systems, can make all the difference in performing accurate repairs. These intricate systems are designed to support the vehicle’s performance, so knowing their layout will empower you to address issues more effectively.

By having a visual reference, you can easily pinpoint which parts require attention or replacement. This helps avoid unnecessary disassembly, saving time and effort while ensuring precision in your work. Proper identification of the individual sections is crucial for maintaining the long-term reliability and safety of your vehicle.

How to Use the Parts Diagram Effectively

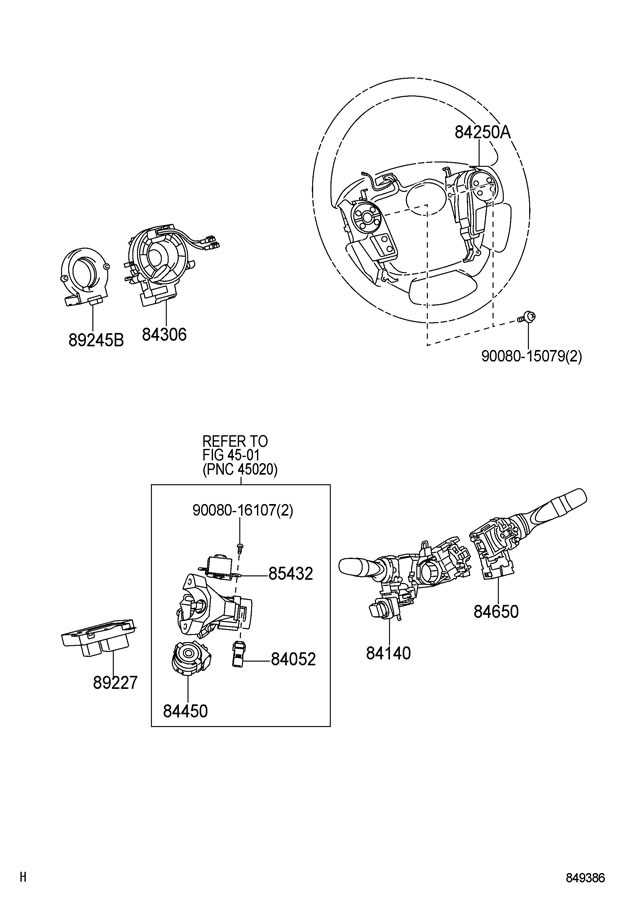

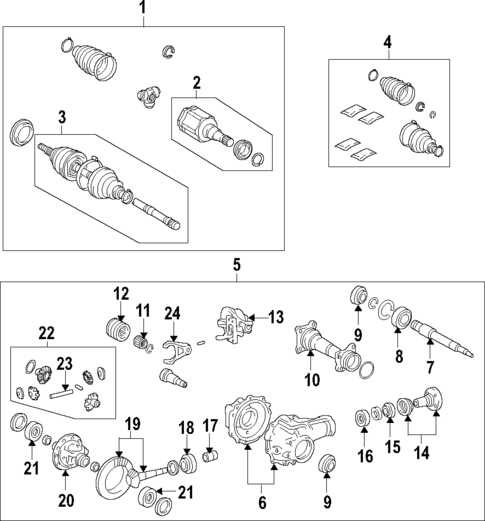

Using a visual reference for identifying and locating various components within your vehicle can drastically improve the repair process. These references are invaluable tools for both professionals and hobbyists, as they allow you to see the exact placement and relationship of each part. Understanding how to interpret these visuals correctly ensures efficient and accurate repairs, minimizing errors and unnecessary disassembly.

Study the Layout Before Starting

Before diving into any maintenance task, take the time to study the entire reference. Familiarize yourself with the general layout and structure of the system you’re working on. Knowing the key areas and their functions will help you navigate the diagram with ease, making it easier to locate specific components when needed.

Follow the Visual Cues for Efficient Repairs

Once you understand the general layout, focus on the individual sections. Look for indicators such as labels, numbers, or arrows that show the direction or sequence of assembly. These cues provide valuable information that guides you through the process, helping you pinpoint which parts need attention or replacement. By following the diagram step-by-step, you can avoid confusion and ensure a smooth repair process.

Common Issues and Replacement Parts for Your Truck

Every vehicle, regardless of age, experiences wear and tear over time. Some components are more susceptible to damage than others, requiring frequent attention and occasional replacement. Understanding the common issues that arise in certain systems can help you stay ahead of potential problems and ensure your truck remains in optimal condition.

Engine and Transmission Problems

One of the most common areas of concern for many truck owners is the engine and transmission system. Over time, parts such as seals, gaskets, and belts can wear out, leading to oil leaks, overheating, or performance issues. Regular inspection and replacing worn-out components like the timing belt or transmission fluid can prevent more severe damage and costly repairs.

Suspension and Brake System Maintenance

The suspension and brake systems are essential for safety and driving comfort. Components like shock absorbers, struts, and brake pads may degrade over time due to regular use. Replacing these parts as they show signs of wear can prevent driving instability, excessive noise, or failure to stop effectively. Timely maintenance of these critical systems ensures both safety and reliability on the road.