Every complex machine relies on a precise arrangement of individual components that work together to ensure smooth operation. A detailed understanding of these elements is essential for anyone involved in maintenance or repairs. Having a clear view of how each part interacts can save time and prevent unnecessary mistakes.

Whether you’re a professional mechanic or a dedicated DIY enthusiast, recognizing the different pieces within your equipment is crucial. By studying the structure and organization of these components, you’ll be able to identify any issues more quickly and address them effectively. Efficiency and accuracy are the ultimate goals when diagnosing and fixing any malfunctions.

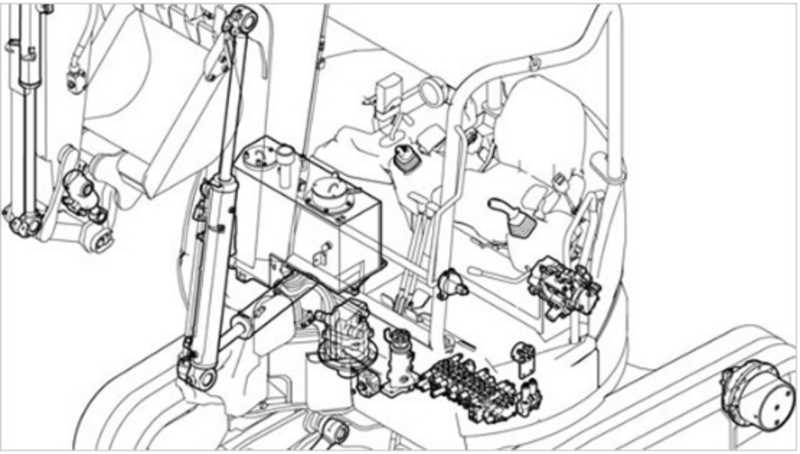

Understanding Branson Tractor Components

Each machine is composed of a variety of essential elements that function together to deliver reliable performance. Understanding the role of each component and how it fits into the overall system is vital for anyone maintaining or repairing the equipment. By identifying the purpose of each part, it becomes easier to troubleshoot and keep the machinery running smoothly.

Key Functions of Core Elements

The main components of a machine serve distinct functions that are interconnected. From the engine to the transmission, each part has a specific job that contributes to the machine’s overall operation. A detailed view of these elements allows for better maintenance and quicker identification of any potential issues.

Recognizing Potential Issues

Knowing the parts and their placement also makes it easier to spot problems early. Whether it’s wear and tear or a malfunction, understanding how the components should look and behave allows for timely interventions. This can prevent costly repairs and help maintain optimal performance over time.

Identifying Key Parts for Efficient Repair

Efficient repair starts with knowing which components are critical for the machine’s operation. Understanding the function of each element allows for faster diagnostics and targeted maintenance. When you know exactly what needs attention, you can prevent unnecessary disassembly and avoid overlooking crucial issues.

Recognizing Essential Elements

Some components are more central to the machine’s functionality than others. Identifying these critical elements, such as the engine or transmission, ensures that you prioritize your repairs effectively. Having a mental map of these parts will guide you in addressing the most important areas first.

Minimizing Repair Time

By knowing the layout and key features of the system, repairs can be done in a more time-efficient manner. This knowledge allows technicians to avoid wasting time on parts that don’t require immediate attention, ultimately speeding up the process and reducing downtime.

How to Use Branson Parts Diagram

To perform effective maintenance or repairs, it’s important to understand how to interpret visual references that outline the layout of a machine’s components. These guides offer a clear view of the equipment’s structure, helping you identify specific parts and their connections. Properly using such references ensures you address the correct areas and speeds up the repair process.

Locating the Right Component

One of the first steps when using such guides is knowing how to find the part you need to focus on. Most visual references are organized in sections or categories, allowing you to pinpoint areas of concern quickly. Make sure to familiarize yourself with the key categories to avoid confusion during repairs.

Understanding Connections and Functions

Once you’ve located a component, the next step is understanding how it connects with other elements in the system. These references often show how parts interact with each other, which is essential when troubleshooting or replacing components. Analyzing the relationships between parts helps you grasp their collective function and ensures better decision-making during repairs.