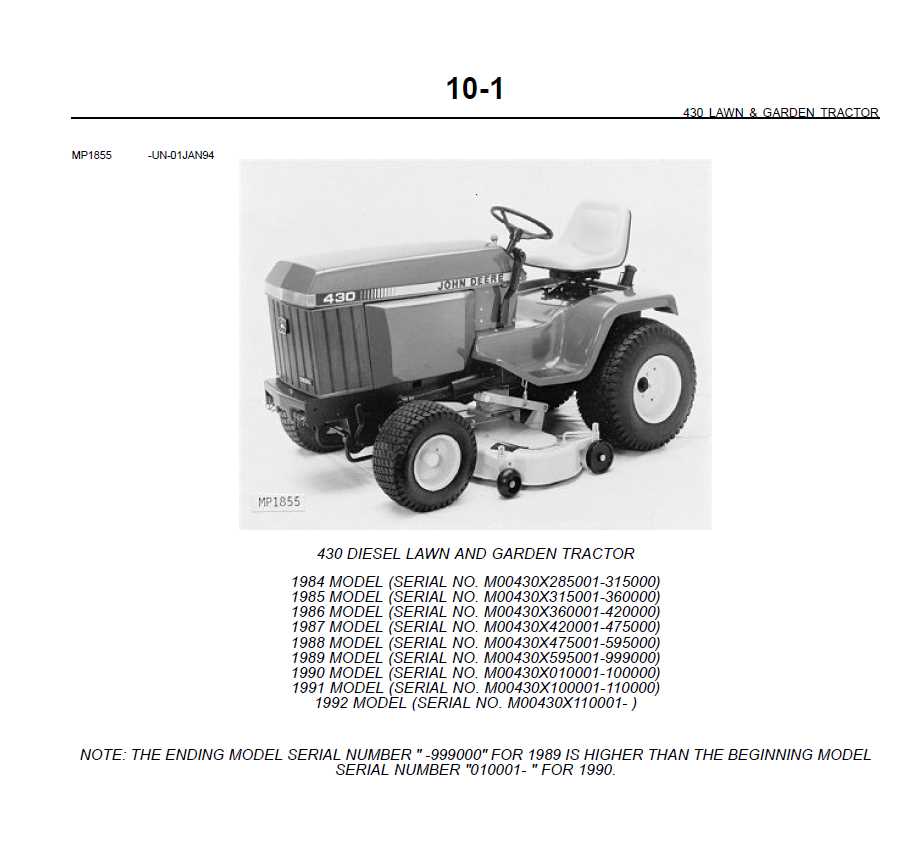

Understanding the structure of heavy machinery is crucial for anyone looking to maintain, repair, or enhance their equipment’s functionality. Knowing how each element fits together ensures smoother operations and longer lifespans. Proper maintenance hinges on the ability to identify parts and their relationships within the system.

With a clear representation of all key elements, it becomes easier to diagnose problems, carry out repairs, and replace worn-out components. Whether you’re a professional mechanic or a machine owner, recognizing the arrangement and function of the various sections plays a vital role in preserving the integrity of the equipment.

Detailed guides and visual aids are invaluable tools, offering a clear view of each part’s role, and they simplify the process of upkeep and troubleshooting. This resource will help you better understand your machinery and the essential steps for keeping it in top working condition.

Understanding Heavy Machinery Components

Every complex machine consists of numerous interconnected elements that work together to perform various functions. To ensure efficient operation, it’s essential to comprehend the role of each individual part within the whole system. Understanding these components not only aids in troubleshooting but also plays a significant role in maintenance and repair tasks.

Key Elements and Their Functions

Each section of a machine serves a specific purpose. Some components, such as the engine, transmission, and hydraulic system, are responsible for providing power and motion. Others, like the frame and axles, offer stability and support. Recognizing the function of each element allows operators and technicians to identify potential issues early and act accordingly.

How Components Interact in the System

The true efficiency of machinery lies in the seamless interaction between its various parts. A malfunction in one area can affect the performance of others. For example, a hydraulic failure can influence the functionality of the entire operational system. Understanding these relationships ensures better diagnostic procedures and more accurate repairs.

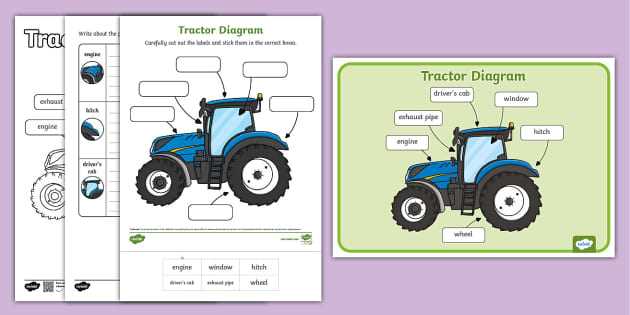

How to Use Machinery Component Diagrams

Using visual guides to identify and understand the various elements of a machine can greatly simplify the maintenance and repair process. These illustrations provide a detailed view of the equipment, allowing users to quickly locate specific parts, understand their function, and assess potential issues. Mastering how to interpret these visuals enhances both troubleshooting and preventive maintenance.

Reading the Visual Representation

Diagrams typically break down the entire system into its smaller sections, highlighting each component’s position and connection. To effectively use these resources, it’s important to familiarize yourself with the legend or key that explains the symbols and labels. This will help you interpret the visual accurately and avoid confusion during repairs.

Steps to Identify and Replace Components

Once you’ve located the part in the diagram, the next step is to assess its condition. For replacement or repair, follow the outlined connections to understand how each part fits into the overall system. Always ensure you have the correct part number and specifications before making a substitution, as even minor discrepancies can impact performance.

Common Issues with Machinery Components

Heavy equipment often experiences wear and tear over time, leading to a variety of mechanical issues. These problems can stem from faulty connections, outdated components, or improper maintenance. Identifying and addressing these concerns early is crucial to preventing costly repairs and ensuring smooth operation.

Some of the most frequent issues include hydraulic failures, engine overheating, and transmission malfunctions. These problems can often be traced back to insufficient lubrication, damaged seals, or worn-out parts that need to be replaced. Regular inspection and maintenance can help mitigate these issues and prolong the life of the machinery.

Electrical failures and system overloads are also common, especially when wiring is damaged or parts become corroded. Keeping components clean and ensuring that all connections are secure can reduce the likelihood of such disruptions. Troubleshooting with accurate knowledge of the system’s layout is essential for quick and effective repairs.